Volute chamber diversion ridge for vortex shaft

A diversion sill and vortex chamber technology, which is applied in the field of flood discharge and energy dissipation, can solve the problems of inability to ensure the air supply of the vortex cavity, the inability to ensure the ventilation of the vortex cavity, and the water flow falling to the bottom of the well. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

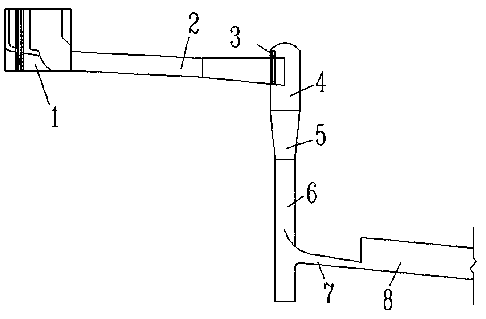

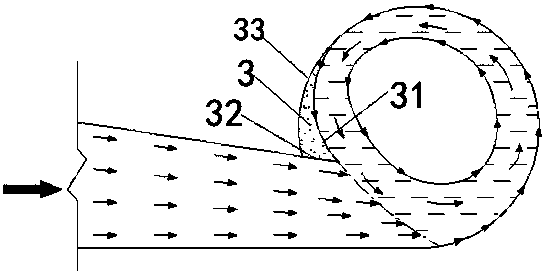

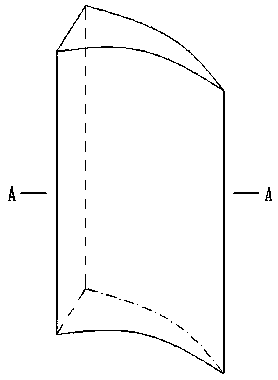

[0026] See Figure 5 , Image 6 with Figure 8 , A vortex chamber diversion sill for a swirling shaft, the vortex chamber sill 3 is provided on the vortex chamber wall surface 33 on the exit side of the upper flat section, and the vortex chamber sill includes rotating water flow in the vortex chamber The direction of the guide arc surface 31 and the connecting surface 32 in the direction of the water flow into the vortex chamber, and the guide arc surface 31 and the connecting surface 32 intersect in the direction of the water flow; along the direction of water flow in the vortex chamber, the guide arc surface 31 and The wall surface of the vortex chamber 4 smoothly transitions and connects; the connecting surface 32 is a curved surface, thereby forming a connecting curved surface, along the direction of water flow into the vortex chamber, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com