Low-nitrogen fuel oil burner

A burner and fuel oil technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problem that the emission has not yet reached the national and local standards, and achieve the effect of reducing the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

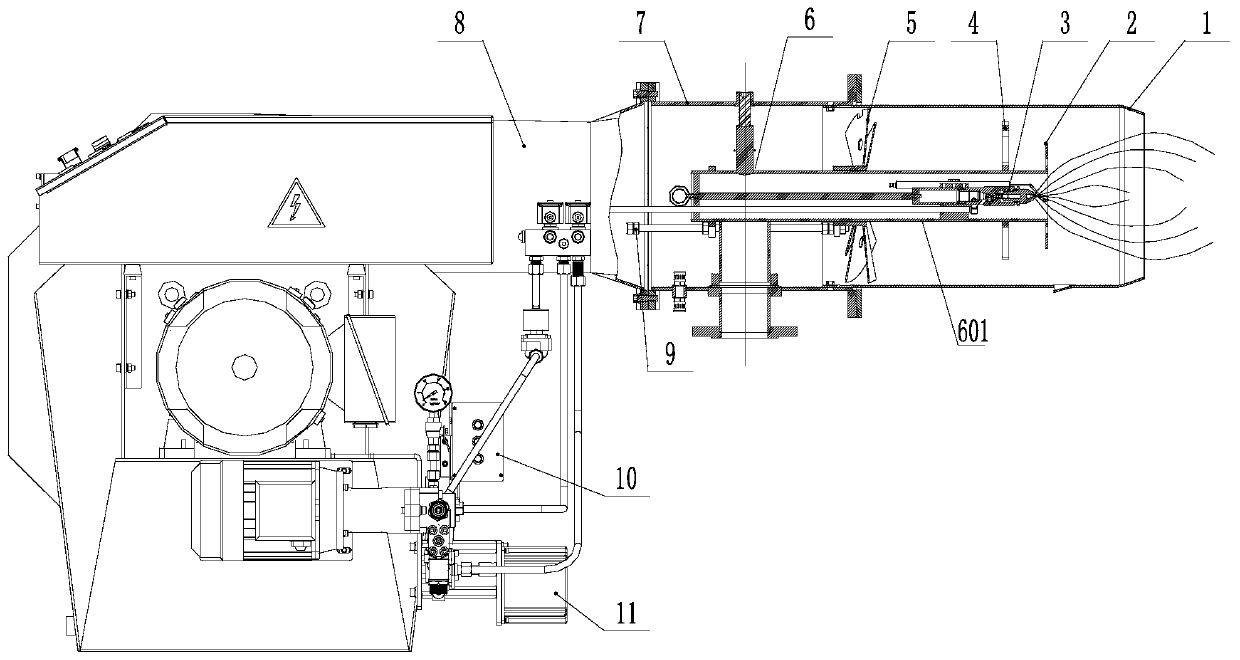

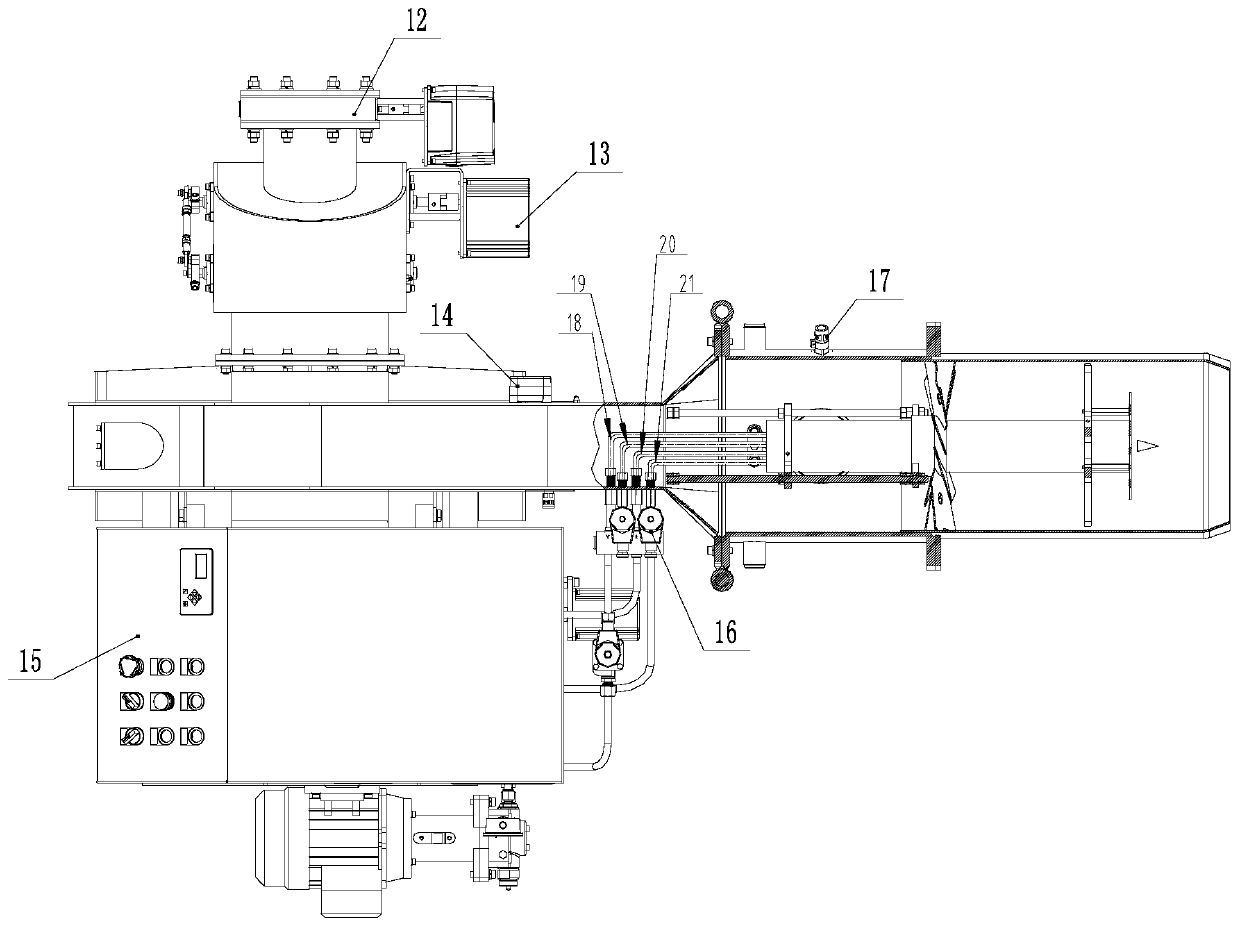

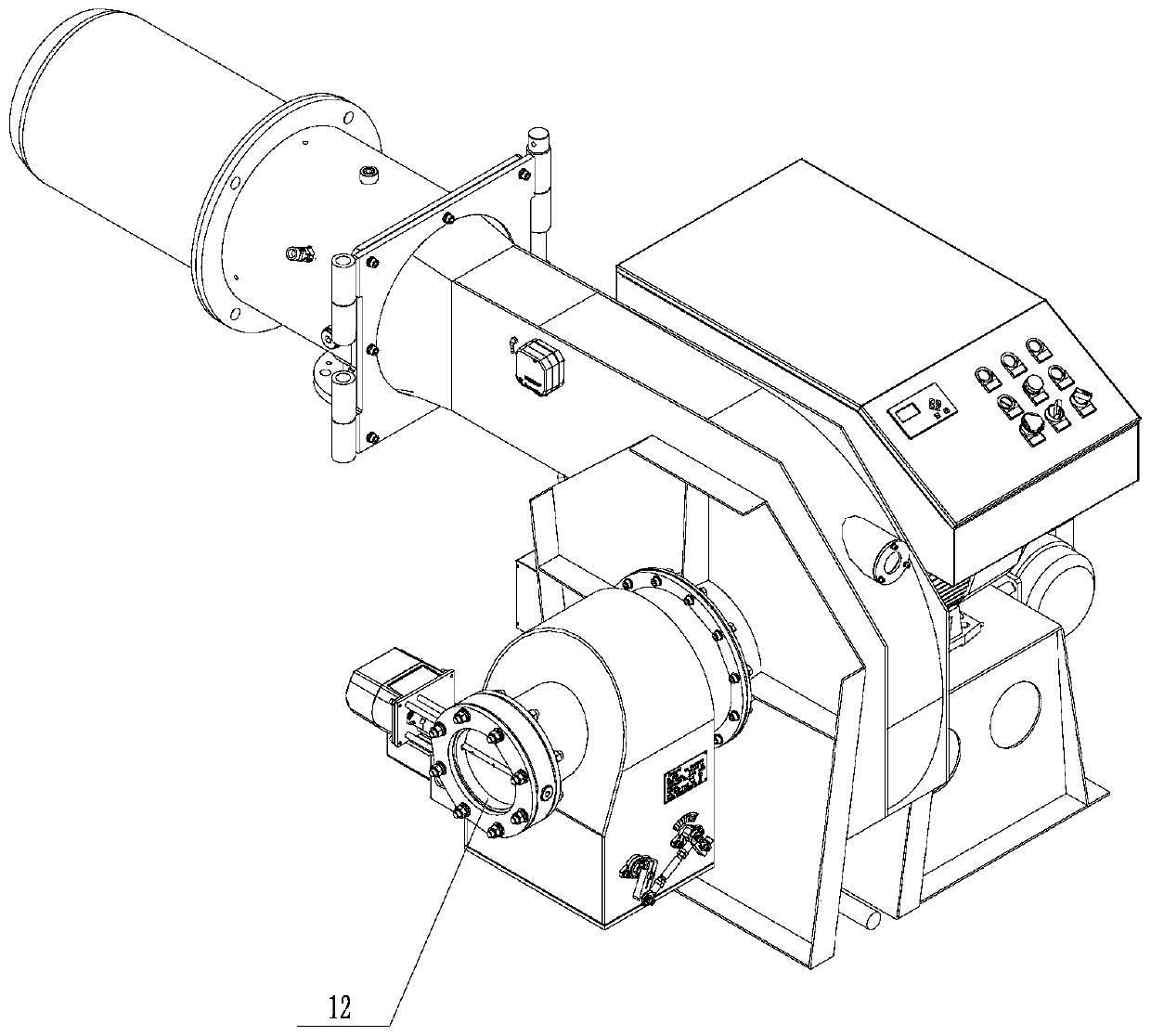

[0034] Such as Figure 1-3 As shown, a low-nitrogen fuel burner includes a burner housing 8, a flame tube 1, a diffuser plate 2, a nozzle and an ignition needle assembly 3, a swirler 5, and a center seat assembly 6. The flame tube 1 passes through a rotating flange The component 7 is connected to the front end of the burner housing 8, and its inner chambers are connected with each other. The front end of the flame tube has a closing opening, the closing angle is 160°, and the closing length is 40mm; the center seat component 6 is installed on the rotating flange component 7 and the flame At the center of the inner cavity of the tube 1, the center seat assembly 6 includes a central inner tube 601, and the diffuser disc 2 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com