Oxygen-enrich gas water heater and work method thereof

A gas water heater and water heater technology, applied in water heaters, fluid heaters, oxidized water/sewage treatment, etc., can solve the problem of low user experience and achieve the effect of easy selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

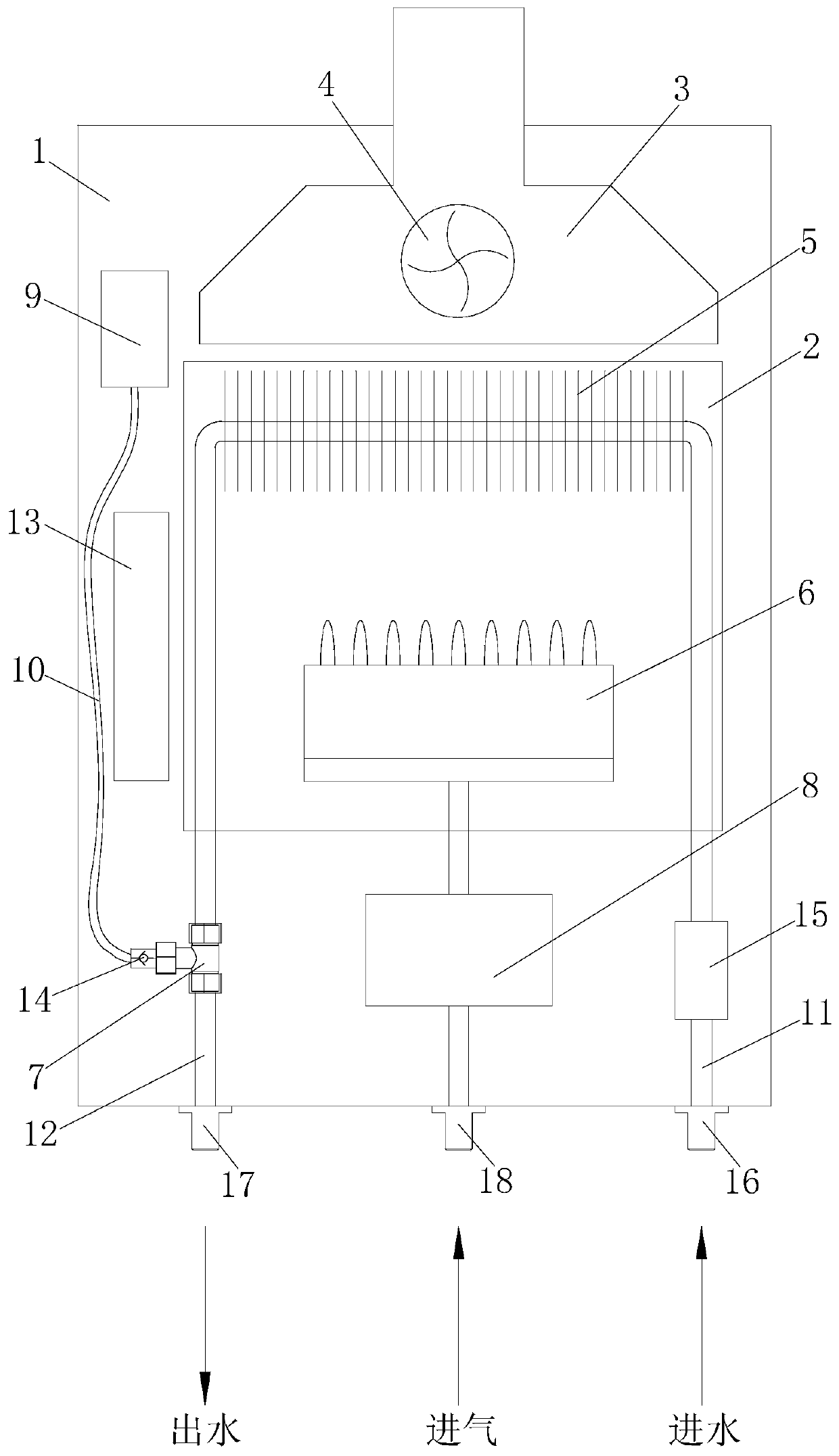

[0045] Example 1 (eg figure 1 , 5 -8 shown).

[0046]The oxygen-enriched gas water heater in this embodiment includes a water heater shell 1, a combustion chamber 2, a smoke collecting hood 3, a fan 4, a heat exchanger 5, a burner 6, a tee joint 7, a gas proportional valve 8, an air pump 9, Inflatable pipe 10, water inlet pipe 11, water outlet pipe 12, controller 13, check valve 14 and water flow sensor 15.

[0047] The combustion chamber 2, the smoke collection hood 3 and the air pump 9 in this embodiment are all located in the water heater shell 1, the smoke collection hood 3 is located above the combustion chamber 2, the fan 4 cooperates with the smoke collection hood 3, the heat exchanger 5 and the combustion chamber The burners 6 are all located in the combustion chamber 2, the burner 6 is connected to the gas proportional valve 8, the air pump 9, the water inlet pipe 11 and the water outlet pipe 12 are all connected to the three-way joint 7, and the water flow sensor 1...

Embodiment 2

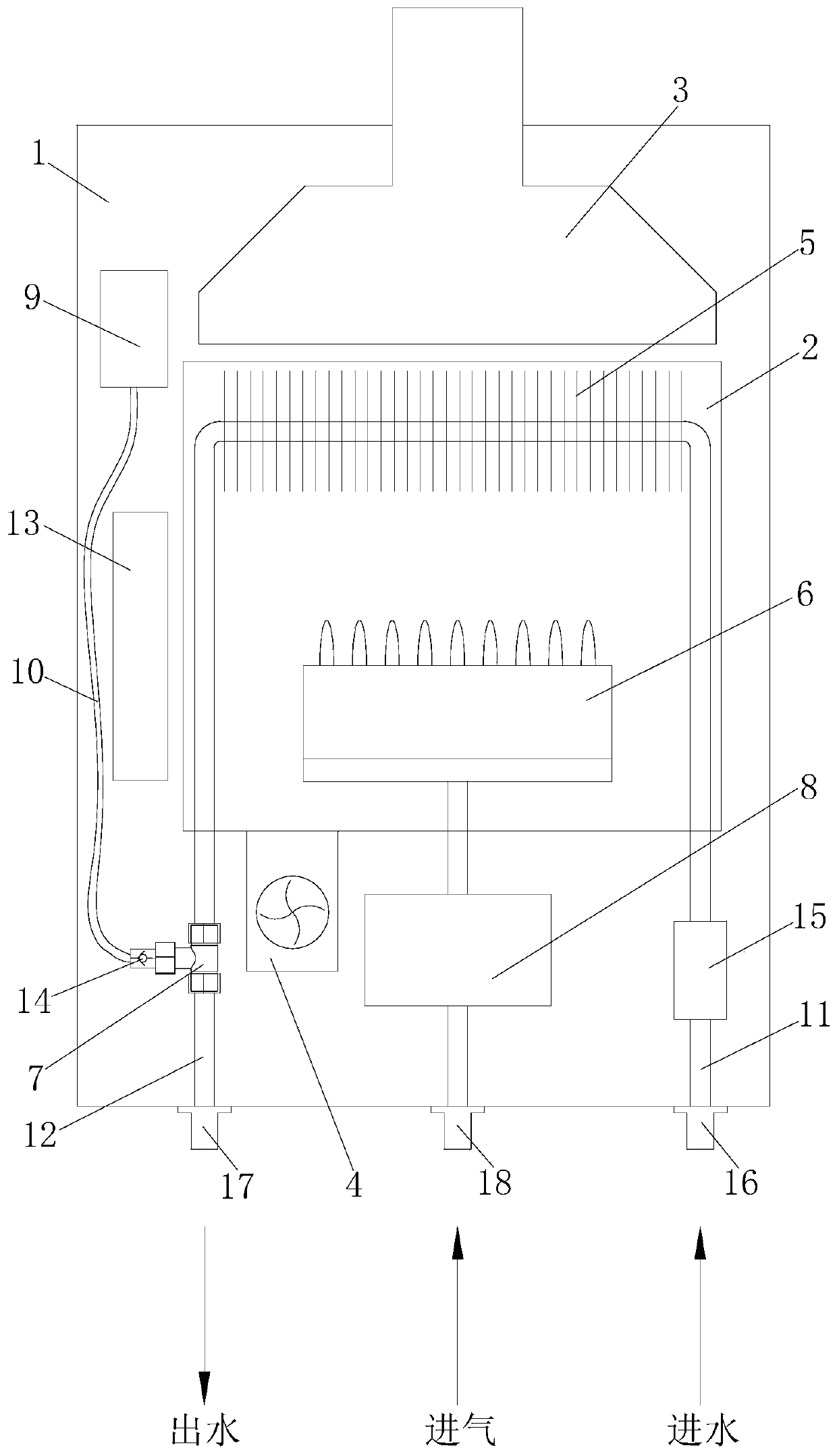

[0059] Example 2 (eg figure 2 , 5 -8 shown).

[0060] The oxygen-enriched gas water heater in this embodiment includes a water heater shell 1, a combustion chamber 2, a smoke collecting hood 3, a fan 4, a heat exchanger 5, a burner 6, a tee joint 7, a gas proportional valve 8, an air pump 9, Inflatable pipe 10, water inlet pipe 11, water outlet pipe 12, controller 13, check valve 14 and water flow sensor 15.

[0061] The combustion chamber 2, the smoke collection hood 3 and the air pump 9 in this embodiment are all located in the water heater shell 1, the smoke collection hood 3 is located above the combustion chamber 2, the fan 4 cooperates with the smoke collection hood 3, the heat exchanger 5 and the combustion chamber The burners 6 are all located in the combustion chamber 2, the burner 6 is connected to the gas proportional valve 8, the air pump 9, the water inlet pipe 11 and the water outlet pipe 12 are all connected to the three-way joint 7, and the water flow sensor...

Embodiment 3

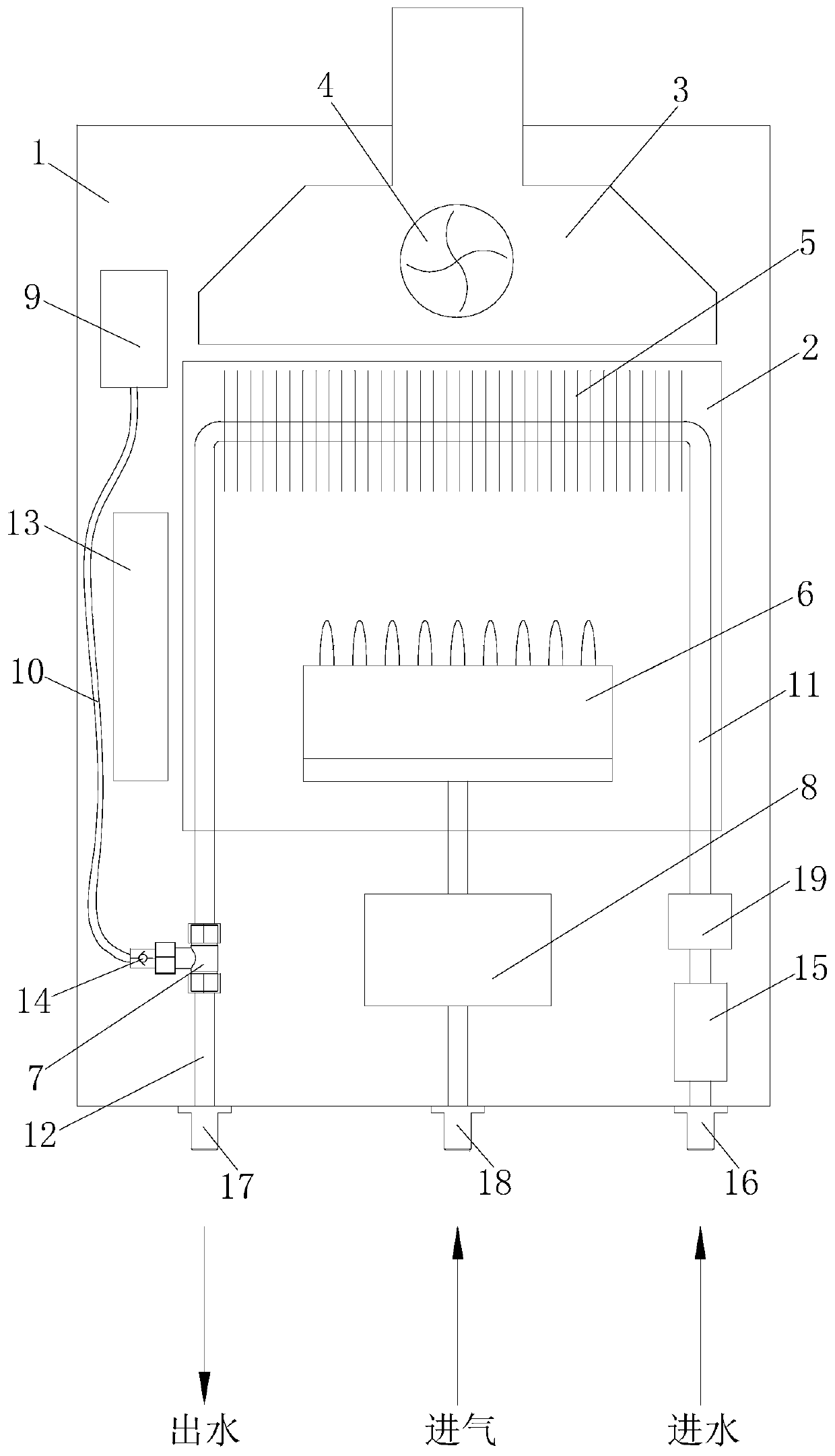

[0073] Example 3 (as image 3 , 5 -8 shown).

[0074] The oxygen-enriched gas water heater in this embodiment includes a water heater shell 1, a combustion chamber 2, a smoke collecting hood 3, a fan 4, a heat exchanger 5, a burner 6, a tee joint 7, a gas proportional valve 8, an air pump 9, Inflatable pipe 10, water inlet pipe 11, water outlet pipe 12, controller 13, check valve 14 and water flow sensor 15.

[0075] The combustion chamber 2, the smoke collection hood 3 and the air pump 9 in this embodiment are all located in the water heater shell 1, the smoke collection hood 3 is located above the combustion chamber 2, the fan 4 cooperates with the smoke collection hood 3, the heat exchanger 5 and the combustion chamber The burners 6 are all located in the combustion chamber 2, the burner 6 is connected to the gas proportional valve 8, the air pump 9, the water inlet pipe 11 and the water outlet pipe 12 are all connected to the three-way joint 7, and the water flow sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com