Auxiliary heat transfer structure of memory

A memory and auxiliary heat technology, applied in electric solid state devices, semiconductor devices, semiconductor/solid state device parts, etc. Good abrasiveness, wear resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

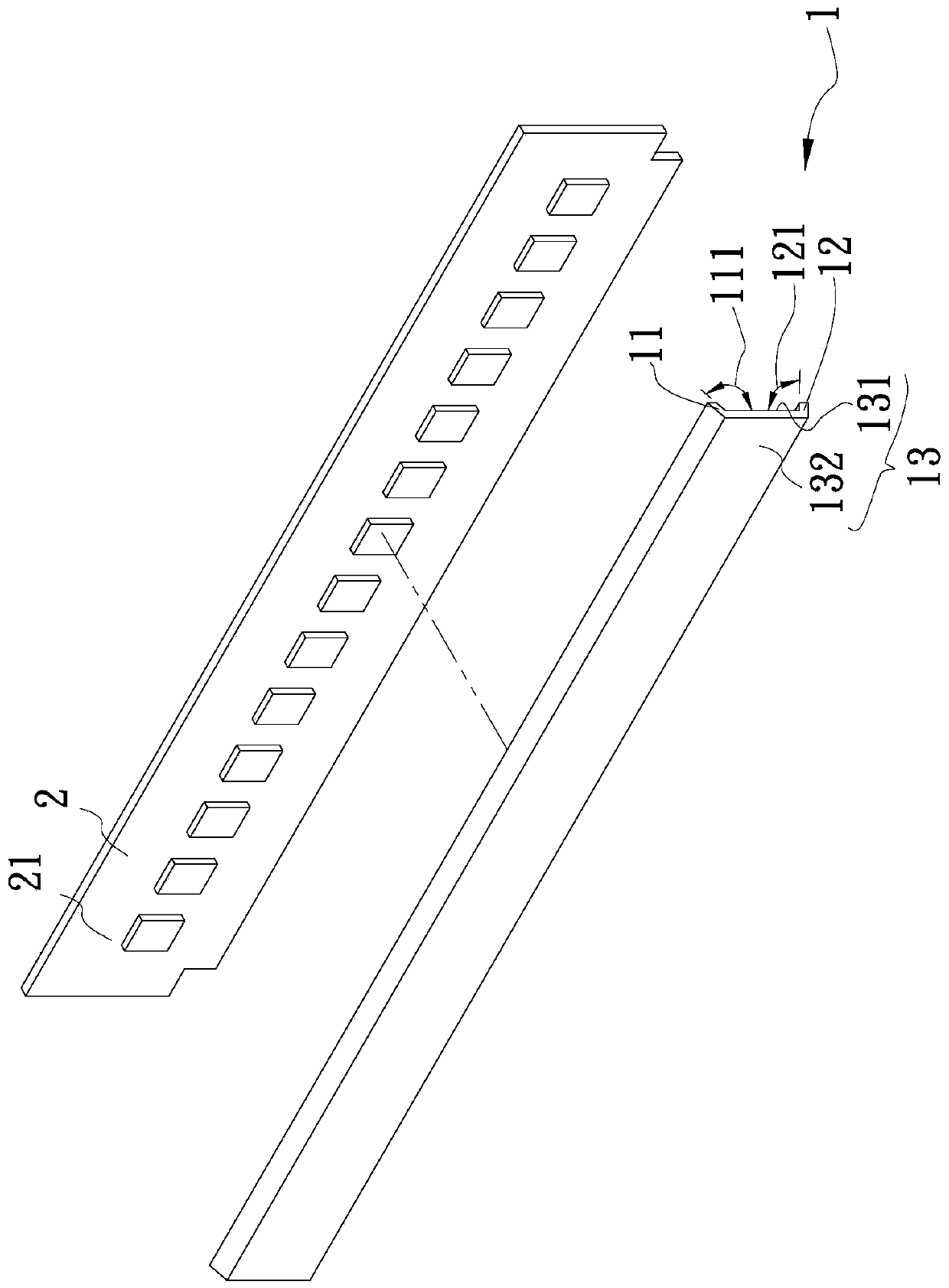

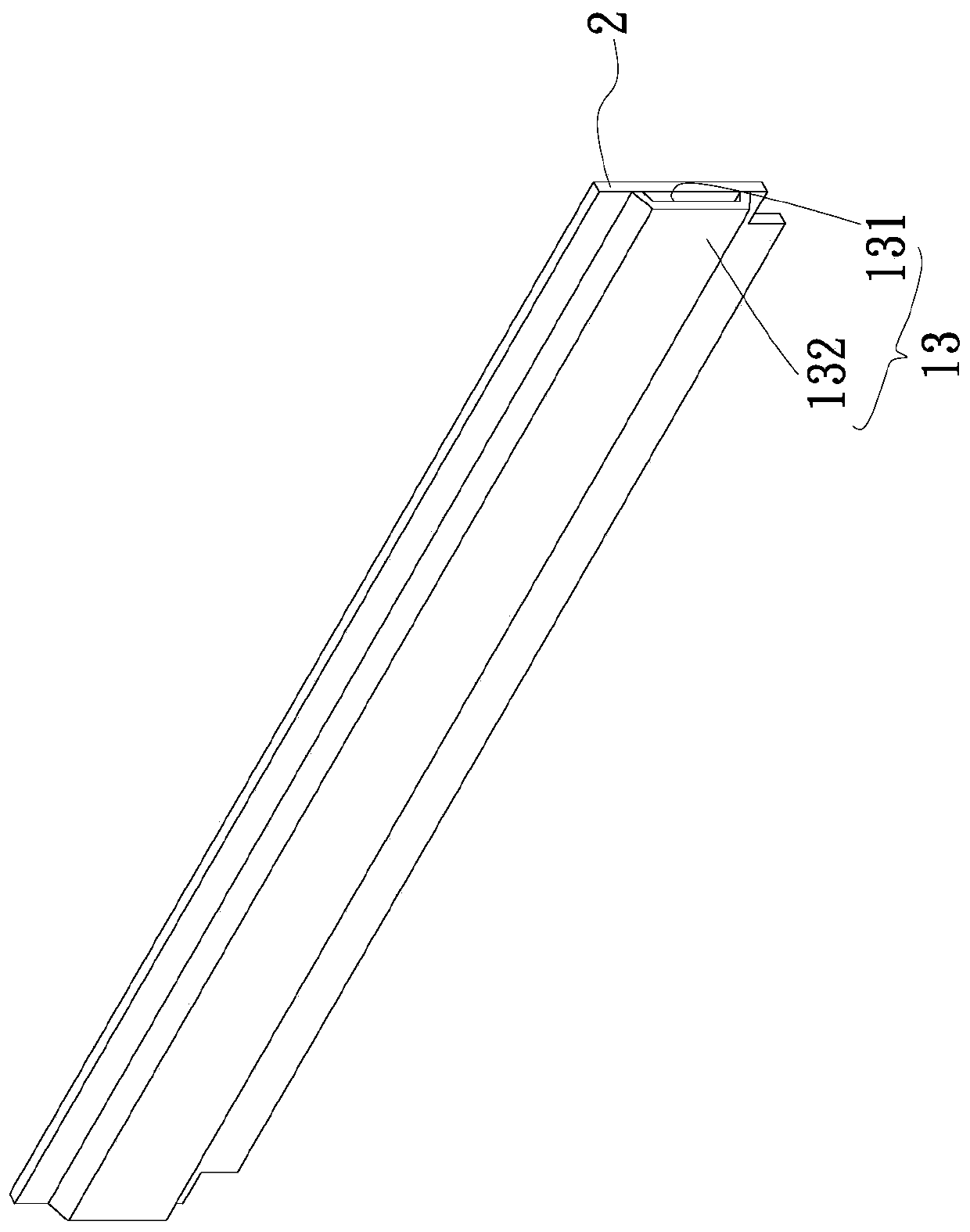

[0027] see figure 1 , Figure 1a , figure 2 , is a three-dimensional exploded, cross-sectional and combined view of the first embodiment of the memory-assisted heat transfer structure of the present invention. As shown in the figure, the memory-assisted heat transfer structure of the present invention is combined with at least one memory unit and a water-cooling component correspondingly It is assumed that the memory auxiliary heat transfer structure includes: a body 1;

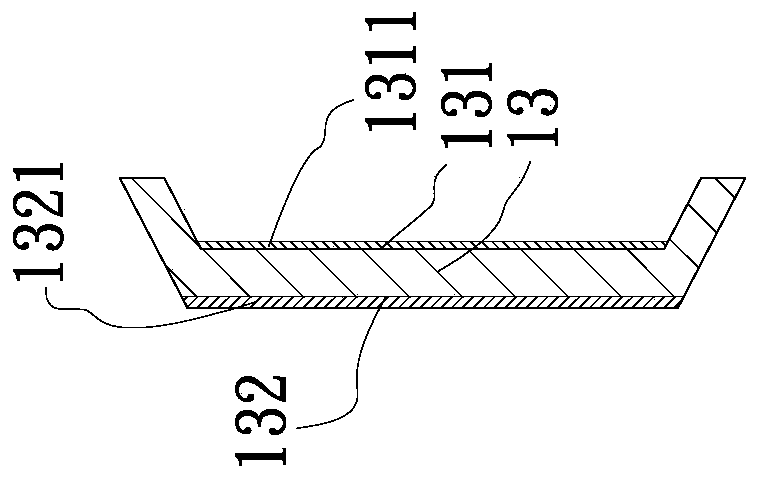

[0028] The main body 1 has a first end 11, a second end 12 and an intermediate section 13. 1. There may be an included angle or a curved surface or an arc surface between the two ends 11 and 12, wherein the included angle is a first included angle 111 and a second included angle 121, and the first and second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com