Heat exchanger

A technology of heat exchangers and oxides, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as unsuitable heat exchangers, and achieve the effect of maintaining antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the heat exchanger according to the present invention will be described in more detail with reference to the drawings. Expressions of singular number used in the present invention shall include expressions of plural number unless a different meaning is clearly indicated in the context.

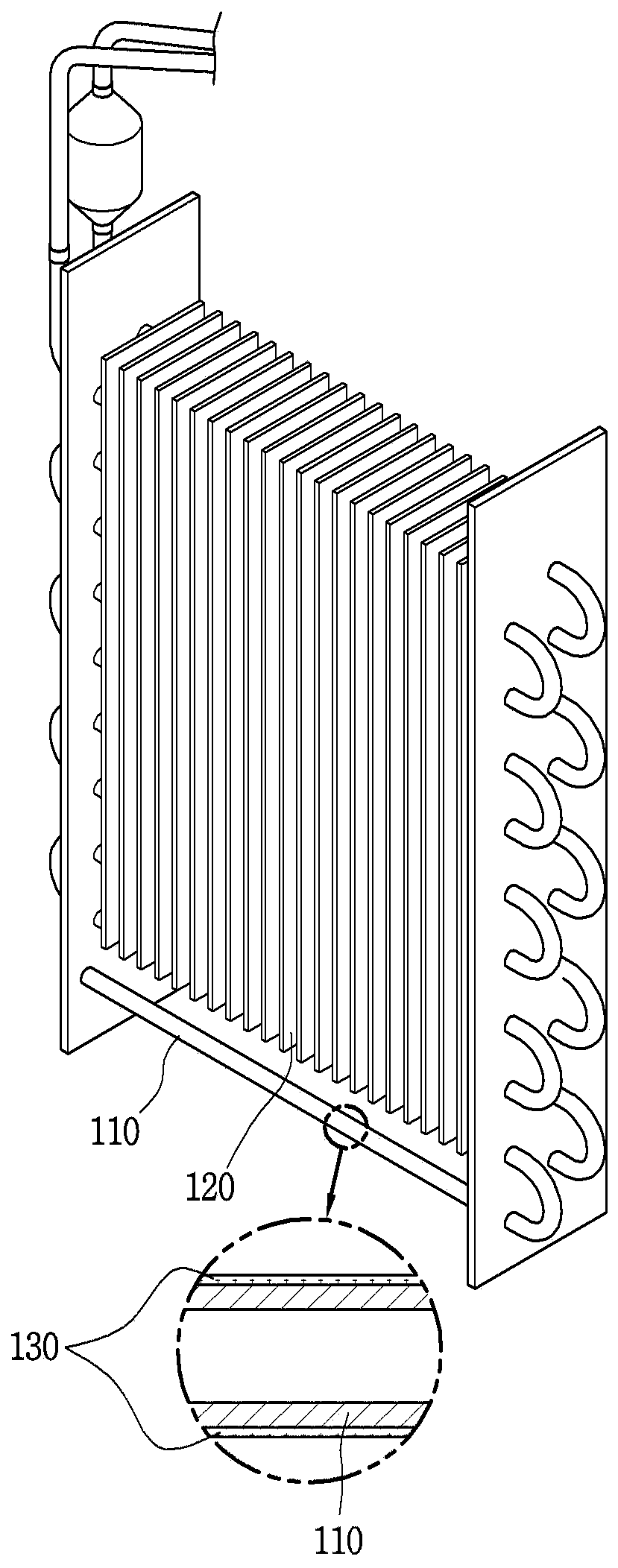

[0033] figure 1 It is a conceptual diagram showing an example of the heat exchanger provided by this invention.

[0034] The refrigerant tube 110 forms a flow path of a heat exchange fluid. The heat exchange fluid may be, for example, a refrigerant. The refrigerant pipe may pass through the cooling fins in a straight line, change directions outside the cooling fins, and repeatedly pass through the cooling fins again.

[0035] The cooling fins 120 are used to increase the heat exchange efficiency of the heat exchanger by expanding the heat exchange area. The cooling fins are coupled to the refrigerant tubes. if refer to figure 1 , shows that the cooling fins are formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com