Sucrose-free hard ice cream and preparation method thereof

A technology of ice cream and hard ice cream, applied in the field of sucrose-free hard ice cream and its preparation, to achieve the effect of reducing the degree of Maillard reaction, low energy, and great market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

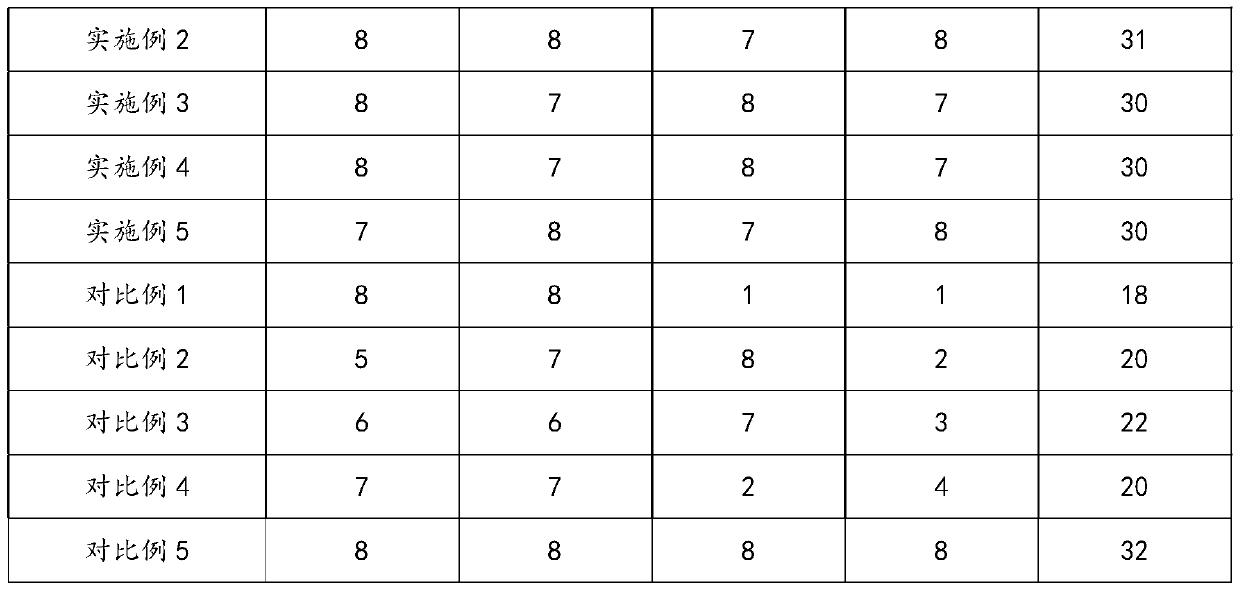

Examples

Embodiment 1

[0024] (1) on the basis of preparing 100 parts of hard ice cream by weight, take 50 parts of whole milk, 15 parts of skim milk, 2 parts of cream, 0.25 parts of steviol glycosides, 5 parts of erythritol and 3 parts of stabilizer, The rest is supplemented with water, mixed and stirred evenly to obtain a mixture.

[0025] (2) Homogenize the mixture at 20MPa and 60°C.

[0026] (3) The homogenized mixture is sterilized at 90°C for 5 minutes, and then rapidly cooled to 0°C after completion.

[0027] (4) The obtained feed solution was subjected to aging treatment at 2° C. for 5 h.

[0028] (5) Freezing the aged feed liquid, and then canning and molding after completion;

[0029] (6) After filling, the product is hardened at -50°C, and then stored at a low temperature after completion to obtain the ice cream provided by the present invention.

Embodiment 2

[0031] (1) on the basis of preparing 100 parts by weight of hard ice cream, take by weighing 10 parts of whole milk, 15 parts of skim milk, 10 parts of cream, 0.5 part of steviol glycoside, 5 parts of erythritol and 2 parts of stabilizer, The rest is supplemented with water, mixed and stirred evenly to obtain a mixture.

[0032] (2) Homogenize the mixture at 20MPa and 50°C.

[0033] (3) Sterilize the homogenized mixture at 90°C for 10 minutes, and then quickly cool it to 4°C.

[0034] (4) The obtained feed solution was subjected to aging treatment at 4° C. for 3 h.

[0035] (5) Freezing the aged feed liquid, and then canning and molding after completion;

[0036] (6) After filling, the product is hardened at -30°C, and then stored at a low temperature after completion to obtain the ice cream provided by the present invention.

Embodiment 3

[0038] (1) Based on the preparation of 100 parts by weight of hard ice cream, weigh 30 parts of whole milk, 8 parts of skim milk, 6 parts of cream, 5 parts of D-psicose and 1 part of stabilizer, and add the rest with water , mix and stir evenly to obtain a mixture.

[0039] (2) Homogenize the mixture at 18MPa and 60°C.

[0040] (3) Sterilize the homogenized mixture at 80°C for 10 minutes, and then quickly cool it down to 1°C.

[0041] (4) The obtained feed solution was subjected to aging treatment at 2° C. for 4 hours.

[0042] (5) Freezing the aged feed liquid, and then canning and molding after completion;

[0043] (6) After filling, the product is hardened at -50°C, and then stored at a low temperature after completion to obtain the ice cream provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com