Laundry detergent and preparation system and preparation process thereof

A technology for preparing systems and laundry detergents, which can be applied in the directions of liquid degassing, liquid degassing by vibration, foam dispersion/prevention, etc., and can solve problems such as incomplete defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

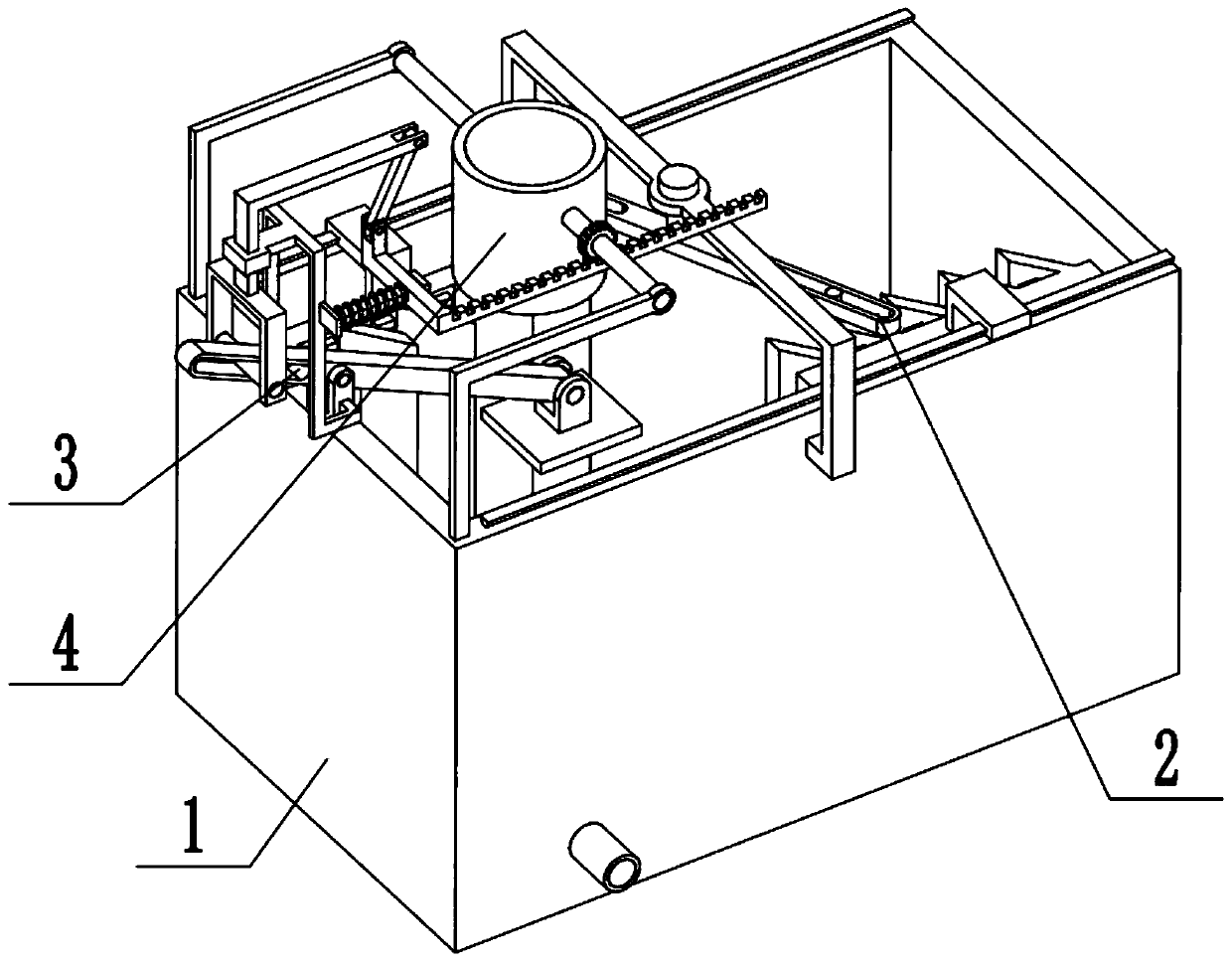

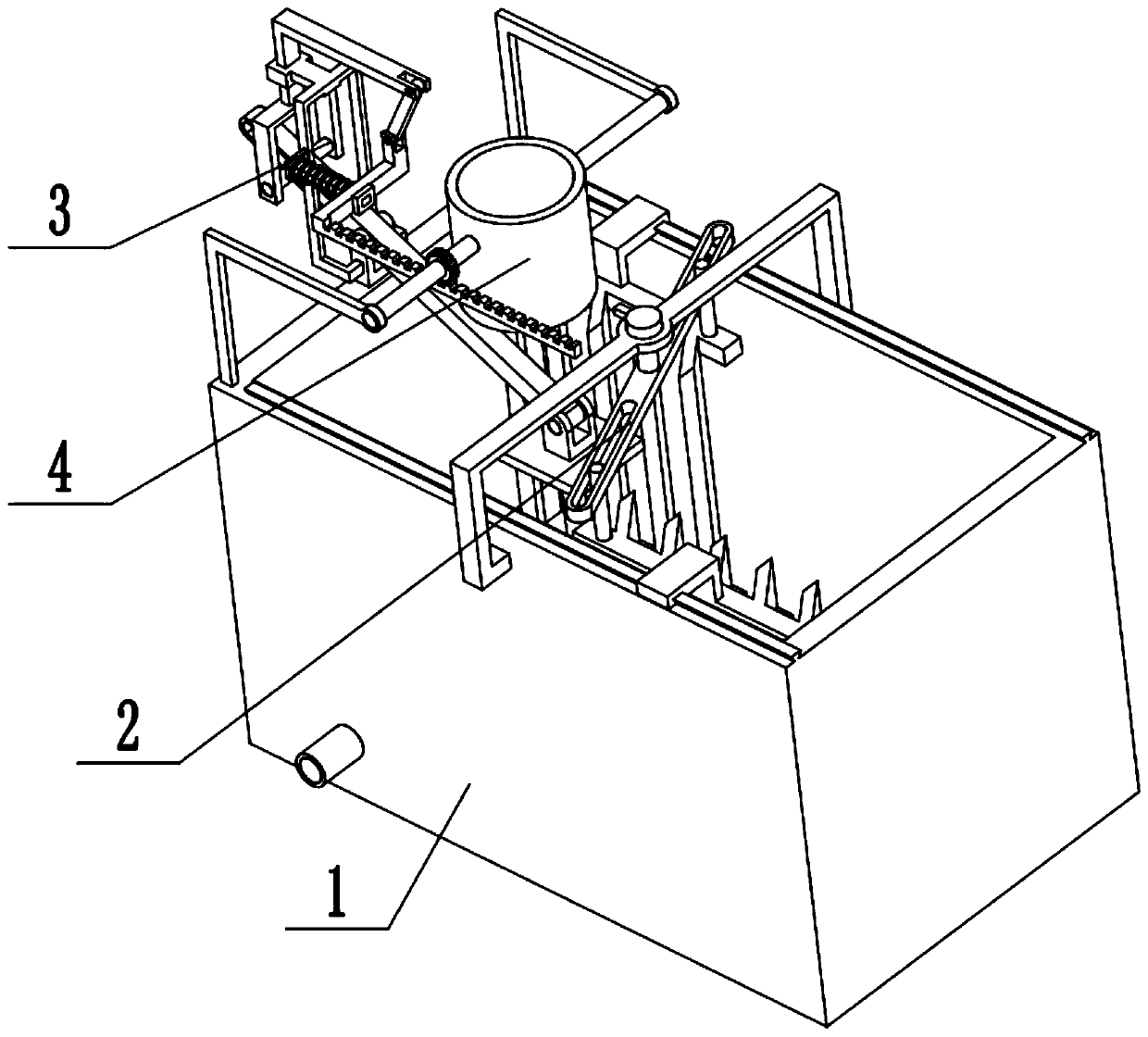

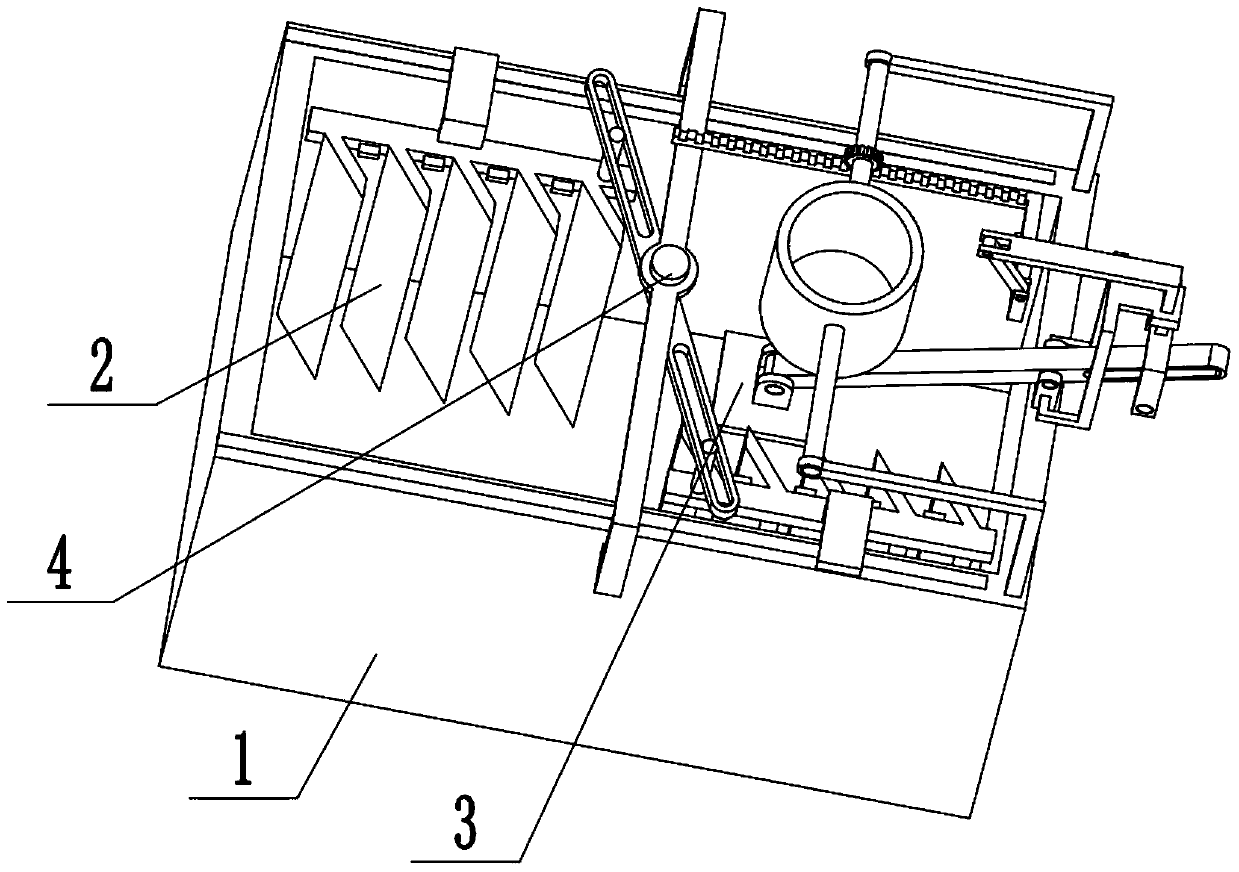

[0031] Combine below Figure 1-7Describe this embodiment, a laundry liquid preparation system, including a stirring box 1, a stirring component 2, an antifoaming agent control mechanism 3 and a defoaming agent pouring mechanism 4, and the stirring component 2 is matched and connected in the stirring box 1 , the stirring assembly 2 drives the laundry liquid in the stirring box 1 to stir and mix evenly. Mechanism 4 is mated and connected, and defoamer control mechanism 3 is used to drive defoamer dumping mechanism 4 to pour the defoamer into the stirring box 1 . When in use, put the laundry liquid to be processed into the stirring tank 1, pour a sufficient amount of defoamer into the defoamer pouring mechanism 4, and start the stirring assembly 2 to stir the laundry liquid in the stirring tank 1. Stir and mix, and at the same time carry out the first level of physical defoaming of the foam in the laundry detergent. When the amount of foam continues to increase, the buoyancy of ...

specific Embodiment approach 2

[0033] Combine below Figure 1-7 To illustrate this embodiment, the lower end of the stirring box 1 is fixedly connected and communicated with the drain pipe 1-1 with a control valve, and the upper end of the stirring box 1 is symmetrically provided with two trapezoidal slide rails 1-2, and the stirring assembly 2 is connected with two trapezoidal slide rails 1-2. The processed laundry liquid is discharged through the control discharge pipe 1-1.

specific Embodiment approach 3

[0035] Combine below Figure 1-7 To illustrate this embodiment, the stirring assembly 2 includes a driving motor 2-1, a motor frame 2-2, a double-slot rod 2-3, a driving rod 2-4, a stirring plate fixing frame 2-5, and an L-shaped sliding seat 2 -6. The stirring plate 2-7 and the ultrasonic generator 2-8; the drive motor 2-1 is fixedly connected to the motor frame 2-2, the motor frame 2-2 is fixedly connected to the upper end of the stirring box 1, and the drive motor 2- The output shaft of 1 is fixedly connected to the double-slot rod 2-3, and the two driving rods 2-4 are respectively slidably connected to the two ends of the double-slot rod 2-3, and the two driving rods 2-4 are respectively fixedly connected to the two stirring plates On the fixed frame 2-5, the upper ends of the two stirring plate fixed frames 2-5 are respectively fixedly connected to an L-shaped sliding seat 2-6, and the two L-shaped sliding seats 2-6 are respectively slidably connected to two trapezoidal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com