Prefabricated concrete sandwich heat preservation board production device

A sandwich insulation board and precast concrete technology, which is applied to supply devices, unloading devices, manufacturing tools, etc., can solve the problems of inconvenient demoulding, affect production efficiency, and single structure, and achieve the effect of convenient control and improvement of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

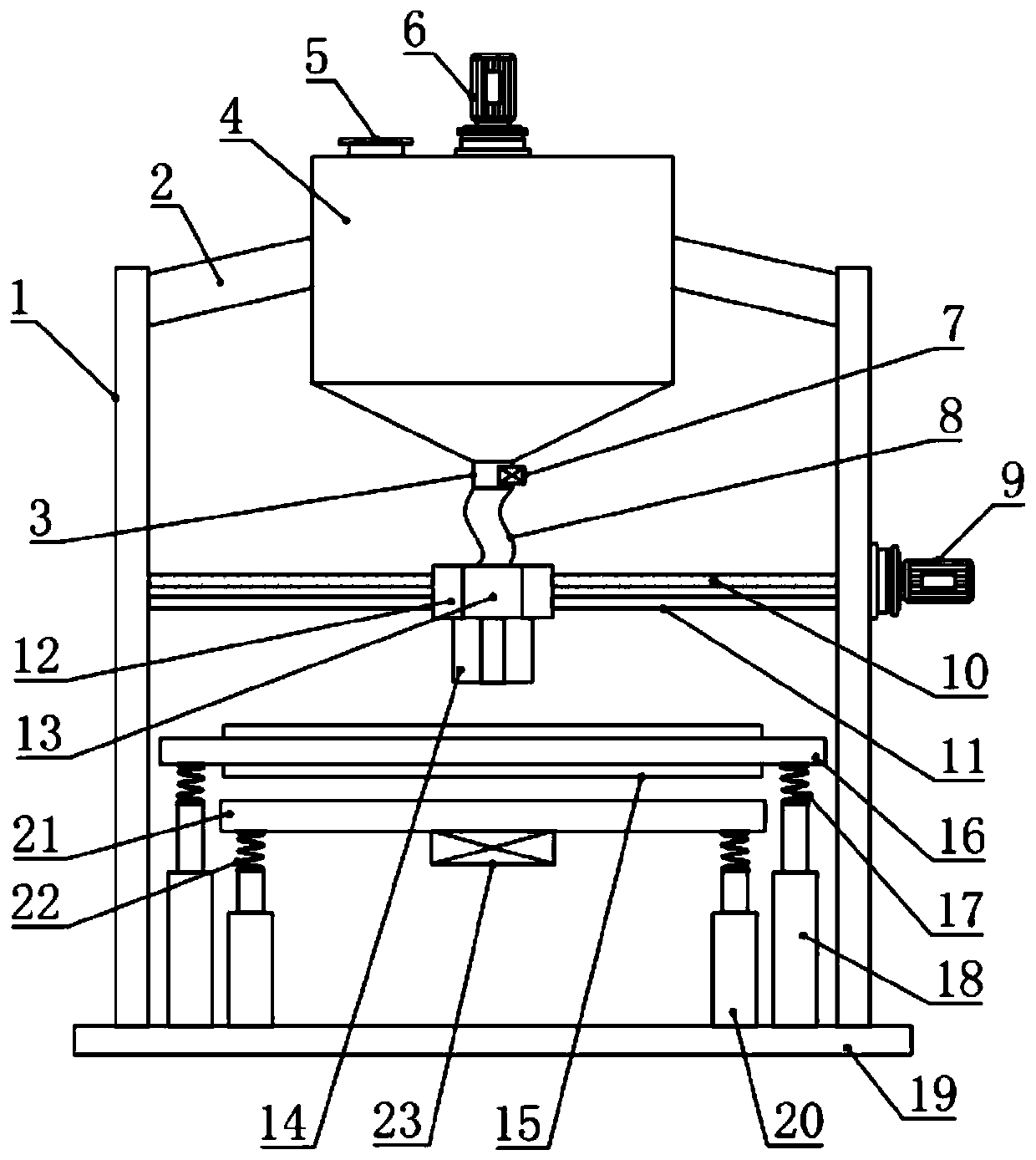

[0021] see figure 1 , in the embodiment of the present invention, a kind of production device of prefabricated concrete sandwich insulation board, comprises side frame 1, support plate 2, concrete discharge pipe 3, concrete mixing box 4, feeding port 5, stirring device 6 and floor seat 19, the Two side frames 1 are installed and fixed on the base plate seat 19, and a concrete mixing box 4 is installed and fixed on the upper part between the two side frames 1 through the support plate 2, and a concrete mixing box 4 is installed on the concrete mixing box 4 for inner A mixing device 6 for mixing and mixing concrete. The top of the concrete mixing box 4 is also provided with a feeding port 5, which is used for adding concrete raw materials through the feeding port 5. The bottom of the concrete mixing box 4 is provided with a concrete discharge pipe 3 , through the concrete discharge pipe 3 for the discharge of the prepared concrete.

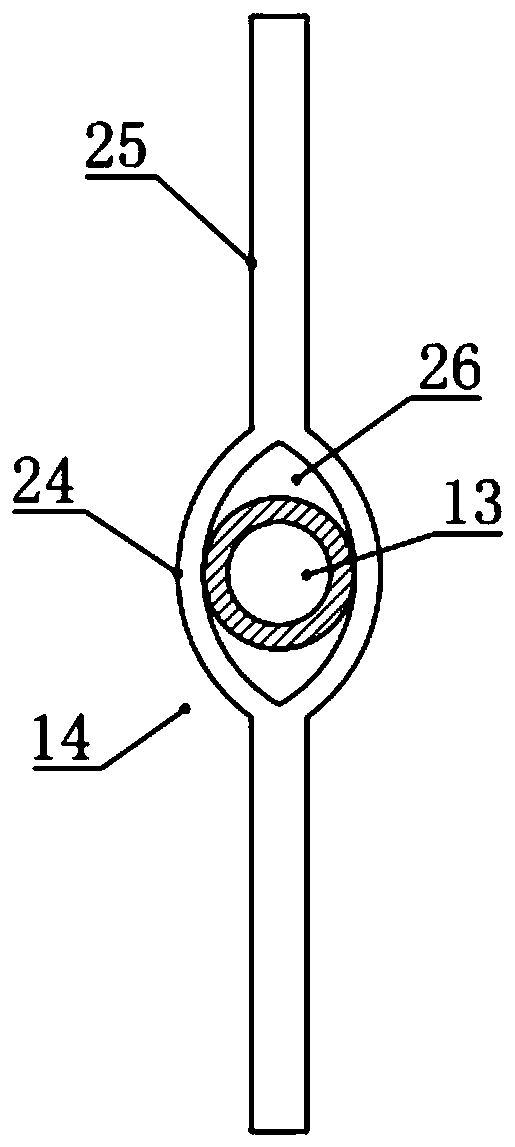

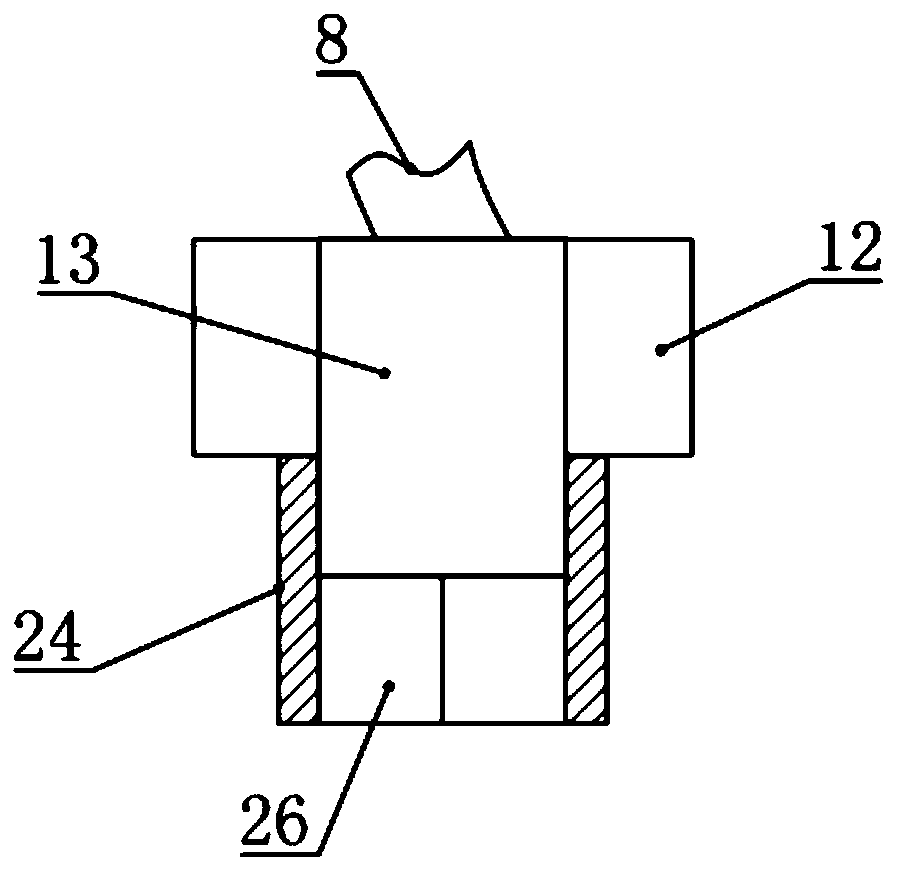

[0022] The concrete discharge pipe 3 is also...

Embodiment 2

[0025] see Figure 1-5 , the difference between this embodiment and embodiment 1 is:

[0026] In this example, if Figure 5 As shown, the prefabricated frame 15 is a rectangular frame, and the outer fixing plate 16 is installed and fixed on the outside of the prefabricated frame 15. The first elastic telescopic assembly includes a first spring 17 and a first telescopic cylinder 18. The bottom of the fixed plate 16 is fixed with a plurality of first springs 17 , the lower end of the first springs 17 is fixed with a first telescopic cylinder 18 , and the cylinder body of the first telescopic cylinder 18 is fixed on the base plate seat 19 .

[0027] In this example, if figure 1 As shown, the bottom support plate 21 is a rectangular structure arranged in conjunction with the prefabricated frame 15, and the top view projection outline of the bottom support plate 21 is located outside the top view projection outline of the prefabricated frame 15, that is, the bottom support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com