Soft anti-tear mesh cloth for vamps and preparation method thereof

A tear-resistant and soft technology, applied in the field of mesh cloth, can solve the problems of not being able to improve softness and tear resistance, not being able to improve service life, and not being able to wear normally, so as to be suitable for popularization and use, prevent external collisions, prevent The effect of outside influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

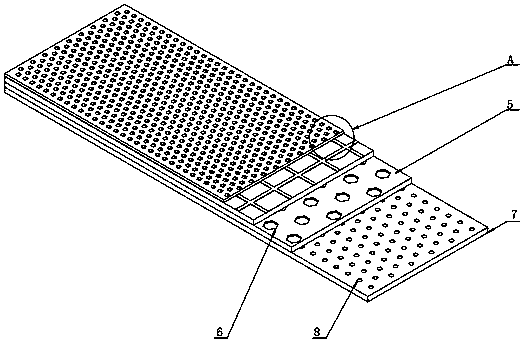

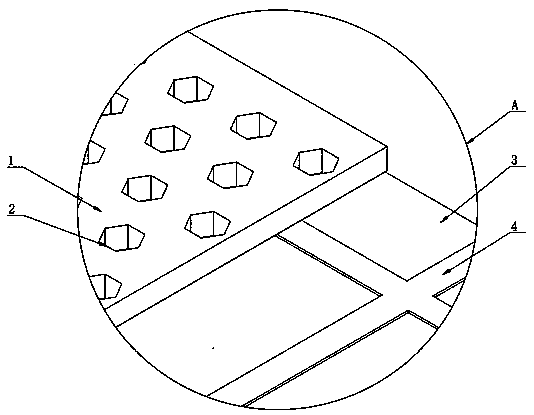

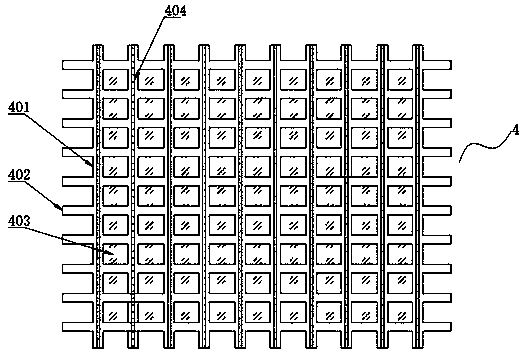

[0043] Such as Figure 1-4 As shown, the present invention provides a technical solution, a soft and tear-resistant mesh for shoe uppers, including a mesh base layer 1, a through hole 2 is opened on the surface of the mesh base layer 1, and the bottom end of the mesh base layer 1 passes through the tear-proof layer 4 is connected with the breathable layer 3, the bottom of the breathable layer 3 is seamed with a sponge layer 5, the bottom of the sponge layer 5 is seamed with a wear-resistant layer 7, and the bottom of the wear-resistant layer 7 is connected with an activated carbon strip 8 and an anti-skid strip 9, The activated carbon strip 8 is embedded in the wear-resistant layer 7, the anti-slip strip 9 seams and on the surface of the wear-resistant layer 7, the thickness of the wear-resistant layer 7 is 0.25 mm, the anti-skid thickness pattern on the surface of the anti-slip strip 9 is 0.10 mm, and the surface of the sponge layer 5 is provided with a breathable Hole 6, the...

Embodiment 2

[0048] Such as Figure 1-4As shown, the present invention provides a technical solution, a soft and tear-resistant mesh for shoe uppers, including a mesh base layer 1, a through hole 2 is opened on the surface of the mesh base layer 1, and the bottom end of the mesh base layer 1 passes through the tear-proof layer 4 is connected with the breathable layer 3, the bottom of the breathable layer 3 is seamed with a sponge layer 5, the bottom of the sponge layer 5 is seamed with a wear-resistant layer 7, and the bottom of the wear-resistant layer 7 is connected with an activated carbon strip 8 and an anti-skid strip 9, The activated carbon strip 8 is embedded in the wear-resistant layer 7, the anti-slip strip 9 seams and on the surface of the wear-resistant layer 7, the thickness of the wear-resistant layer 7 is 0.25 mm, the anti-skid thickness pattern on the surface of the anti-slip strip 9 is 0.05 mm, and the surface of the sponge layer 5 is provided with air-permeable Hole 6, the...

Embodiment 3

[0053] Such as Figure 1-4 As shown, the present invention provides a technical solution, a soft and tear-resistant mesh for shoe uppers, including a mesh base layer 1, a through hole 2 is opened on the surface of the mesh base layer 1, and the bottom end of the mesh base layer 1 passes through the tear-proof layer 4 is connected with the breathable layer 3, the bottom of the breathable layer 3 is seamed with a sponge layer 5, the bottom of the sponge layer 5 is seamed with a wear-resistant layer 7, and the bottom of the wear-resistant layer 7 is connected with an activated carbon strip 8 and an anti-skid strip 9, The activated carbon strip 8 is embedded in the wear-resistant layer 7, the anti-slip strip 9 seams and on the surface of the wear-resistant layer 7, the thickness of the wear-resistant layer 7 is 0.25 mm, the anti-skid thickness pattern on the surface of the anti-slip strip 9 is 0.10 mm, and the surface of the sponge layer 5 is provided with a breathable Hole 6, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com