A double-layer laminating unit for steel composite slabs

A composite slab and double-layer lamination technology, which is applied in the direction of packaging material feeding device, transportation packaging, packaging, etc., can solve the problems of poor aesthetics and poor sealing, and achieve high processing efficiency, simple structure, and good attachment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

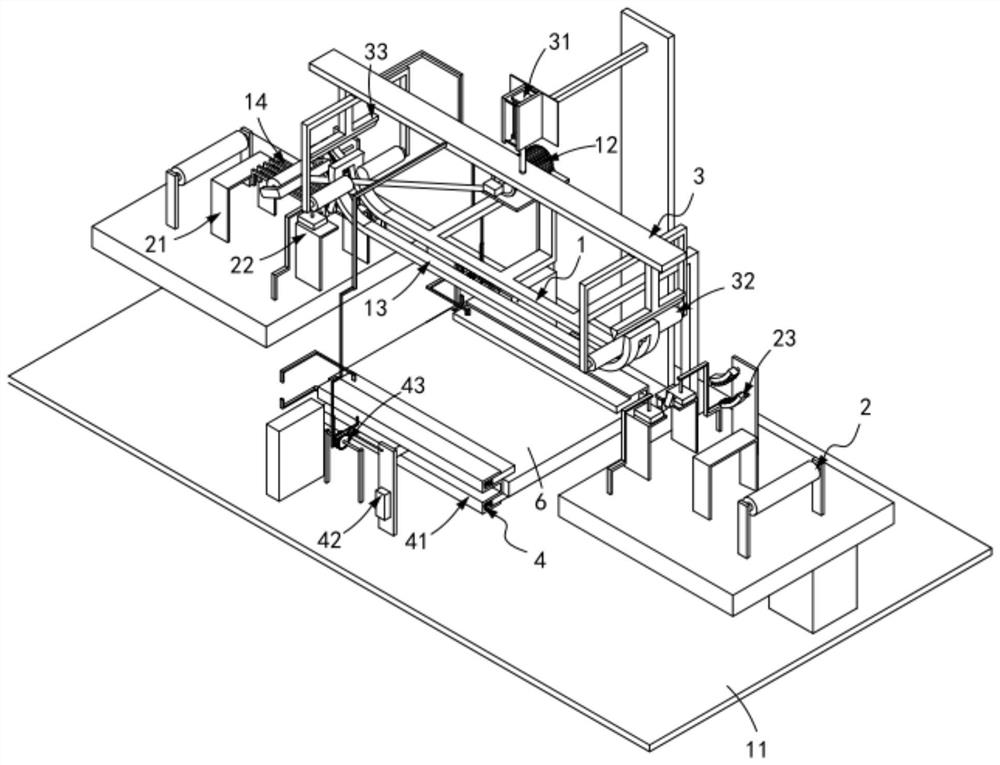

[0062] Such as figure 1 Shown, a kind of steel clad slab double-layer laminating unit, comprising:

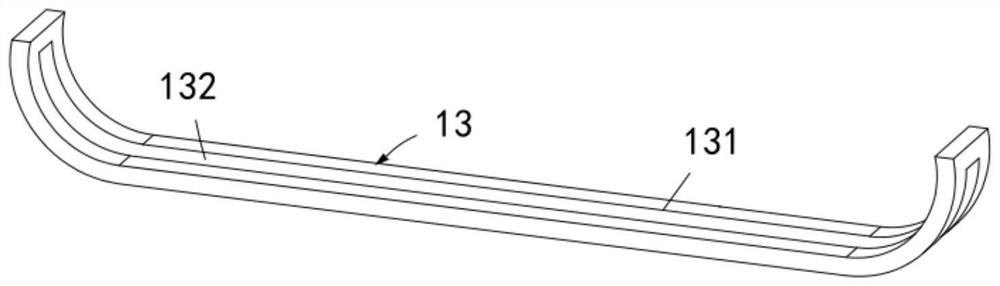

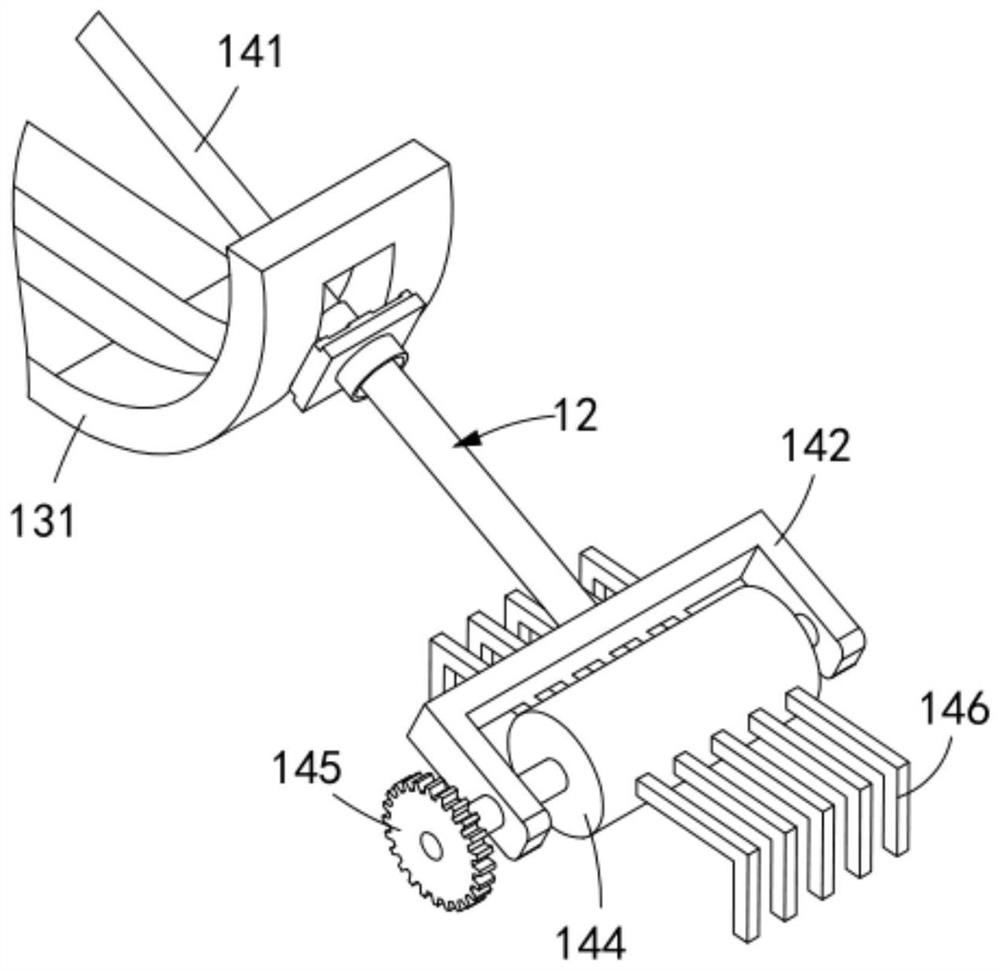

[0063] Reciprocating mechanism 1, described reciprocating mechanism 1 comprises the first driving assembly 12 that is installed on the frame 11, the guide assembly 13 that is arranged on the below of described first driving assembly 12 and is driven along by described first driving assembly 12 The film pulling assembly 14 driven by the guide assembly 13;

[0064] The film feeding mechanism 2 is located on one side of the guide assembly 13 and two groups are arranged symmetrically along the midline in the length direction of the guide assembly 13, which includes the feeding mechanism arranged on the frame 11. The film assembly 21, the limit assembly 22 arranged above the film feeding assembly 21 and in discontinuous contact with the film pulling assembly 14, and the stop assembly 22 arranged on the other side of the guide assembly 13 relative to the film feeding assembly 21 Me...

Embodiment 2

[0112] Such as Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0113] further, such as Figure 9 As shown, the film pressing mechanism 32 includes a first film pressing assembly 321 arranged on one side of the film feeding assembly 21 and a second film pressing assembly 322 arranged on one side of the film releasing assembly 23;

[0114] Both the first film pressing assembly 321 and the second film pressing assembly 322 include a connecting rod a323 whose upper end is fixedly arranged on the second drive assembly 31 and is an elastic structure, arranged horizontally and fixedly connected to the connecting rod a323 The mounting frame 324 and two sets of pressure rollers 325 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com