Broadband high-impedance manganese-zinc ferrite material and preparation method thereof

A manganese-zinc ferrite, high-impedance technology, applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc. Effects of low cost, high DC resistivity, and high Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

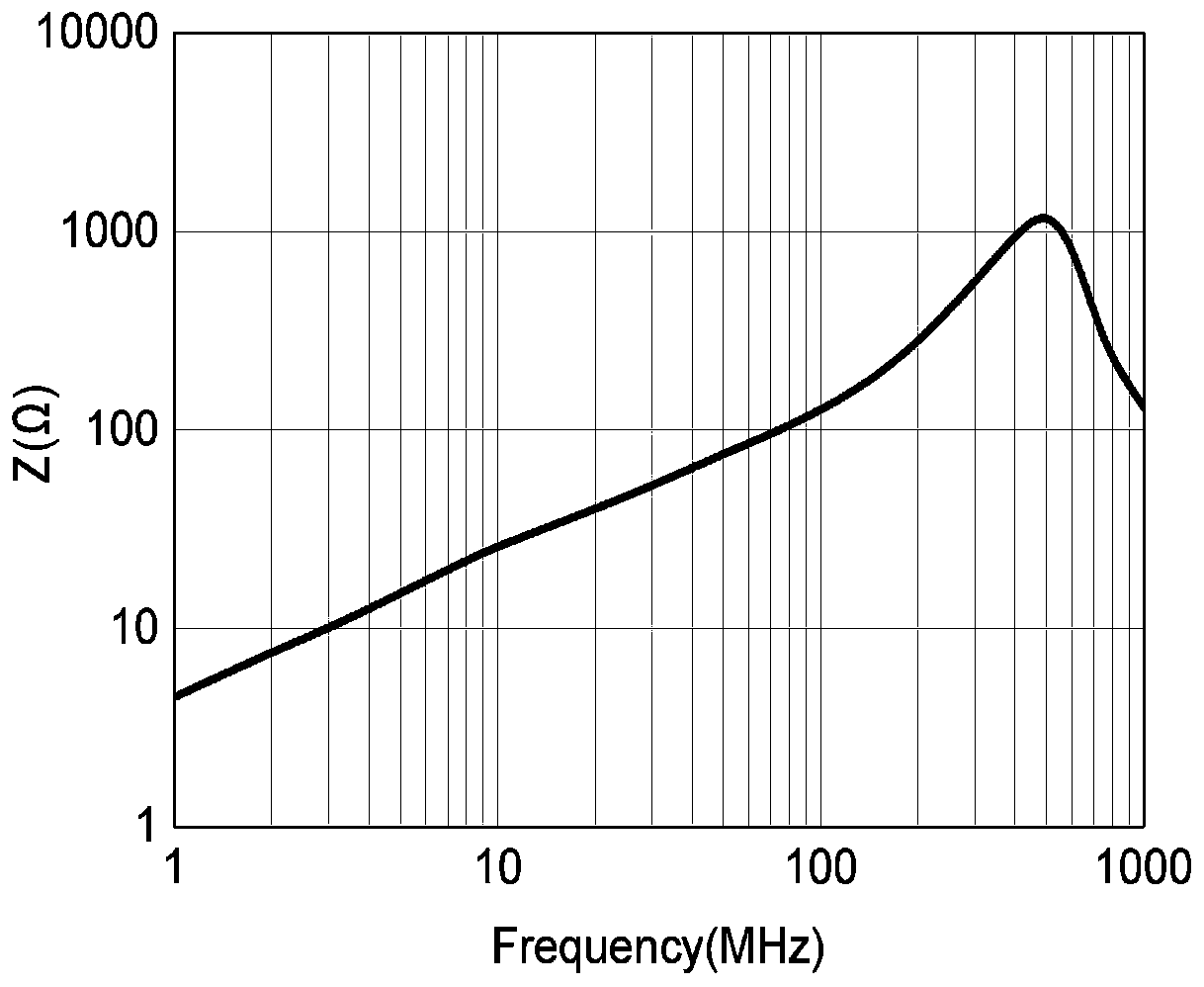

Image

Examples

Embodiment Construction

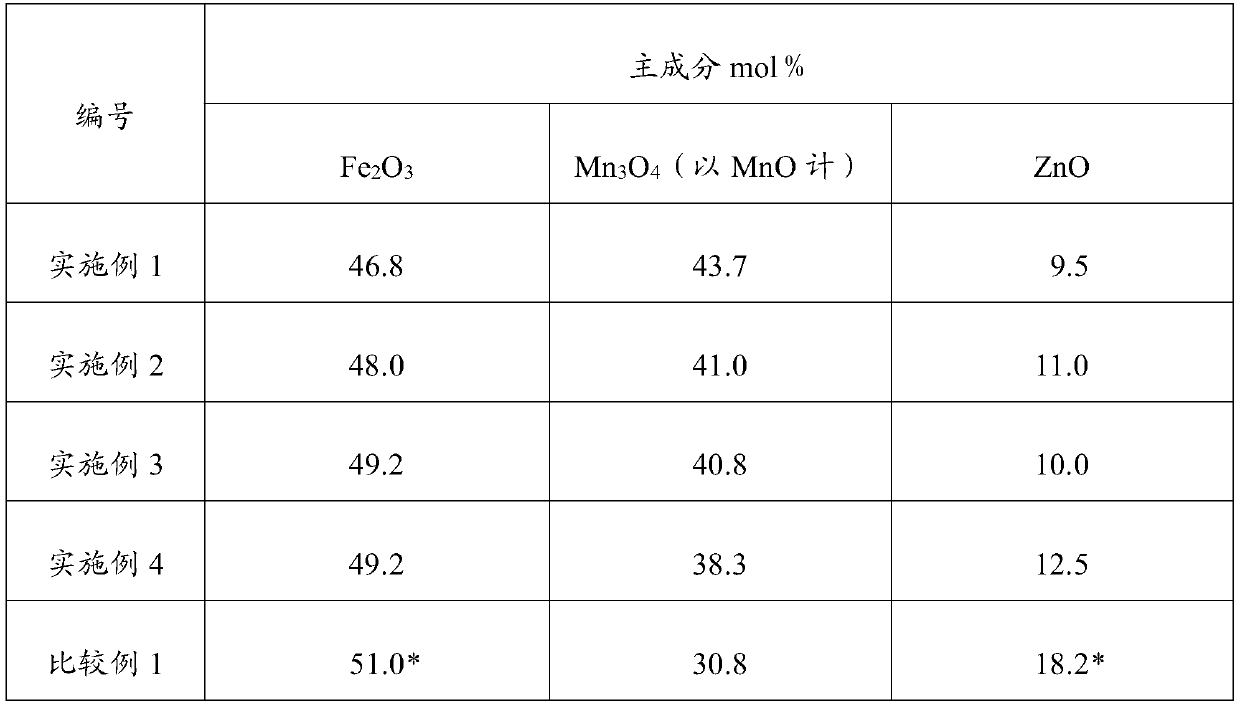

[0025] Examples 1-4 and Comparative Example 1 are based on Fe 2 O 3 , Mn 3 O 4 , ZnO as the main component, the ferrite material obtained with different addition amounts of each main component, put it in a ball mill and mix for 0.5 hours, then take it out and dry it. Using a box-type resistance furnace, the obtained powder was pre-fired at 900°C for 2.5 hours. Then put the pre-fired powder into a ball mill, and add an auxiliary component: 0.008wt% of SiO to the obtained powder based on the total weight of the main component 2 , 0.02wt% CaCO 3 , 0.30wt% Co 2 O 3 ; Then add 50wt% of deionized water and 1.5wt% of the dispersant based on the total weight of the main component for ball milling. Ball mill this powder to an average particle size of about 1.0±0.2μm; based on the total weight of the powder after ball milling, add 7wt% polyvinyl alcohol solution to the powder, mix uniformly to granulate, and compress the granules into OR25×8-15mm ring sample. Finally, in a bell furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com