Preparation method of magnetostriction material

A technique for magnetostrictive materials and preparation steps, which is applied in the field of preparation of magnetostrictive materials, can solve problems such as the decline of dynamic magnetostrictive performance, and achieve the effects of improved stretchable performance, high Curie temperature, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

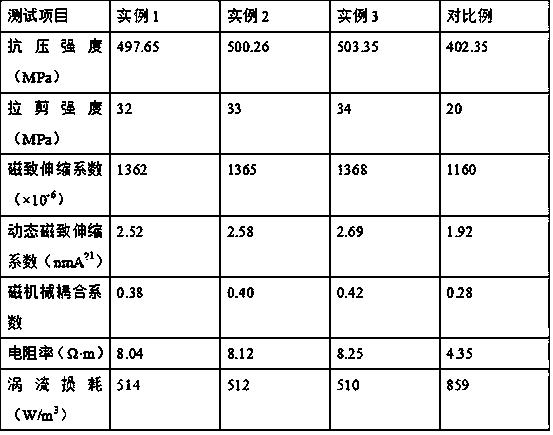

Examples

example 1

[0026] Get 100g pyrolusite ore and place pulverizer in pulverizer, cross 100 mesh sieves and obtain pyrolusite powder, place pyrolusite powder in the reactor, add 40g iron powder, 200mL mass fraction to the reactor and be the concentrated sulfuric acid solution of 45% and 20g of orange peel, stirred and mixed for 20min, moved the reaction kettle into a water bath, heated to 50°C, kept the temperature for 2h, filtered to remove the filter residue, and obtained the leaching solution; added 70g of manganese dioxide to the above leaching solution, heated to 80°C, React for 2 hours to obtain the oxidized leaching solution, continue to add 30 g of manganese carbonate to the oxidized leaching solution, stir until no bubbles are generated, carry out suction filtration on the oxidizing leaching solution, collect the filtrate, transfer the filtrate to a beaker, and add a mass fraction of 25% to the beaker Ammonia, adjust the pH to 6.5, stir for 5 minutes, filter and separate to obtain th...

example 2

[0028] Get 105g pyrolusite ore and place pulverizer in pulverizer, cross 100 mesh sieves and obtain pyrolusite powder, place pyrolusite powder in reactor, add 45g iron powder, 250mL mass fraction to the reaction kettle and be the concentrated sulfuric acid solution of 45% and 25g of orange peel, stirred and mixed for 25 minutes, moved the reaction kettle into a water bath, heated to 52°C, kept the temperature for 2.5h, filtered to remove the filter residue, and obtained the leaching solution; added 75g of manganese dioxide to the above leaching solution, and heated to 85°C , reacted for 2.5 hours to obtain the oxidized leachate, continue to add 35g of manganese carbonate to the oxidized leachate, stir until no bubbles are generated, carry out suction filtration on the oxidized leachate, collect the filtrate, transfer the filtrate to a beaker, and add a mass fraction of 25% to the beaker % ammonia water, adjust the pH to 6.7, stir for 7 minutes, filter and separate to obtain the...

example 3

[0030] Get 110g pyrolusite ore and place pulverizer in pulverizer, cross 100 mesh sieves and obtain pyrolusite powder, place pyrolusite powder in the reactor, add 50g iron powder, 300mL mass fraction to the reactor and be the concentrated sulfuric acid solution of 45% and 30g of orange peel, stirred and mixed for 30min, moved the reaction kettle into a water bath, heated to 55°C, kept the temperature for 3h, filtered to remove the filter residue, and obtained the leaching solution; added 80g of manganese dioxide to the above leaching solution, heated to 90°C, React for 3 hours to obtain the oxidized leaching solution, continue to add 40 g of manganese carbonate to the oxidized leaching solution, stir until no bubbles are generated, carry out suction filtration on the oxidizing leaching solution, collect the filtrate, transfer the filtrate to a beaker, and add a mass fraction of 25% to the beaker Ammonia water, adjust the pH to 7.0, stir for 10 minutes, filter and separate to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com