High-pressure and normal-pressure gas and vacuum all-in-one machine

An all-in-one machine and vacuum technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, machines/engines, etc., can solve the problems of short service life, strong vibration, and large floor space of the pump body, so as to improve the service life and reduce the Effects of noise and vibration, footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

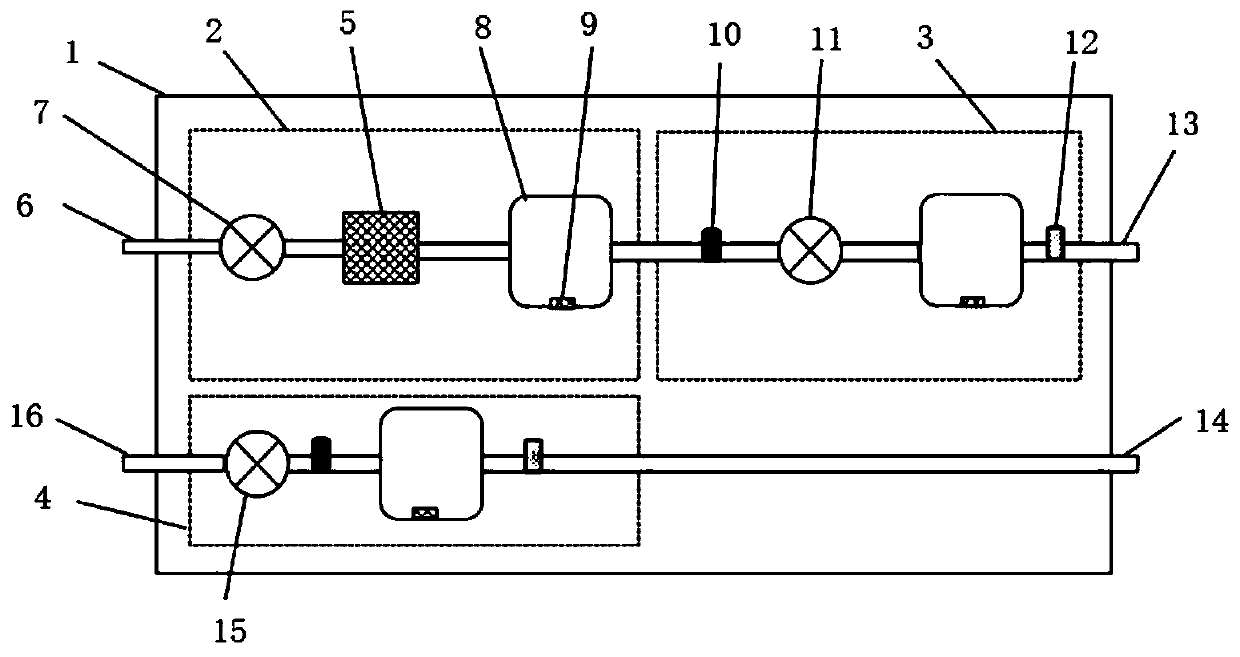

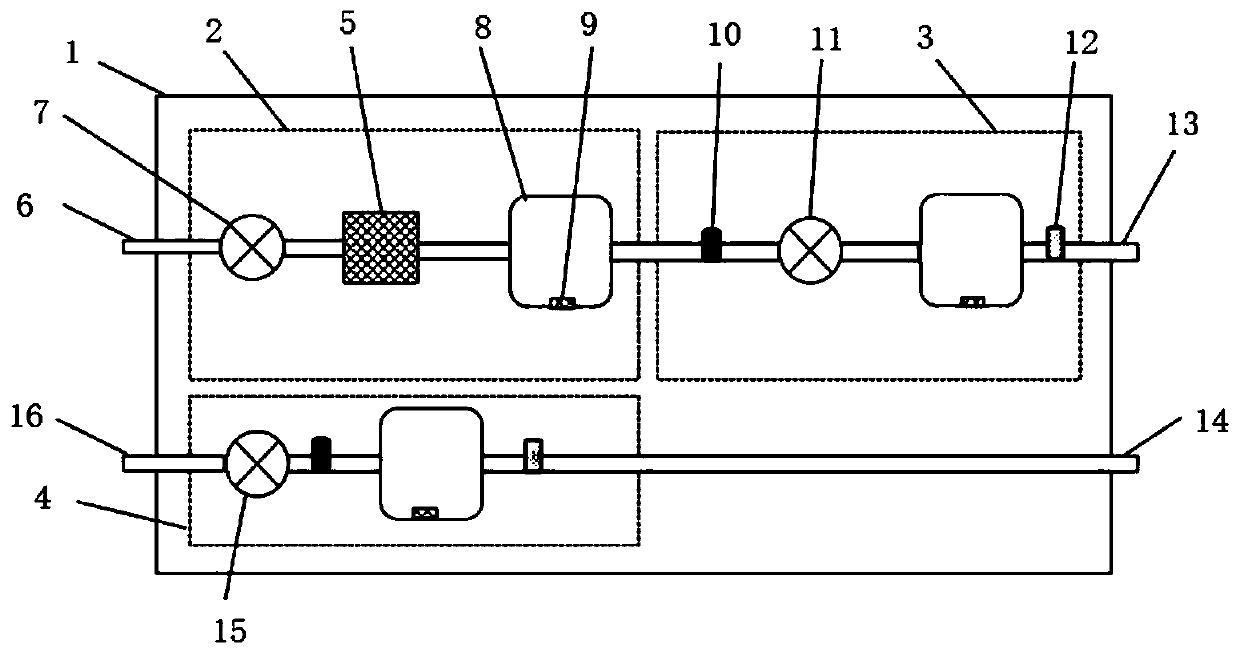

[0049] Such as figure 1 It is a schematic structural diagram of a high pressure, normal pressure and vacuum integrated machine provided by the present invention, the integrated machine includes a box body 1 , an air supply unit 2 , a constant pressure unit 3 and a vacuum unit 4 . The gas supply unit 2 is connected to the constant pressure unit 3 , the gas supply unit 2 provides gas input to the constant pressure unit 3 , and the constant pressure unit 3 pressurizes or processes the gas it receives. The gas filter unit 5 can be installed inside the gas supply unit 2 to filter the input required gas to obtain high-purity gas and output it to the gas supply unit 3. Those skilled in the art can filter the gas filter unit according to specific conditions. 5 is installed outside the gas supply unit 2 or inside or outside the constant pressure unit 3. The gas supply unit 2 includes a gas inlet 6, a compressor 7, a first buffer tank 8, a pressure sensor 9 and the like. The constant ...

Embodiment 2

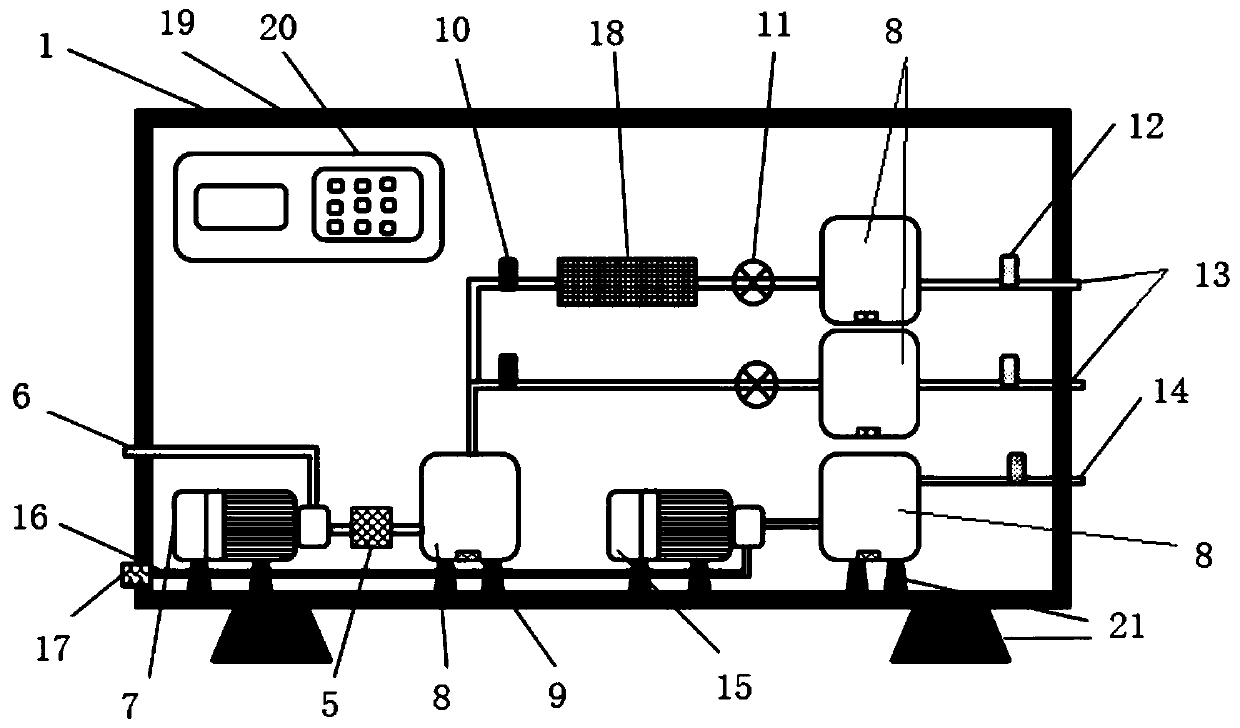

[0054] figure 2 The internal structure diagram of an embodiment of the high-pressure, normal-pressure and vacuum integrated machine provided by the present invention mainly describes the internal structure diagram of the high-pressure nitrogen, high-pressure air, and vacuum integrated machine provided at the same time. A box body 1 is included, and a sound insulation layer 19 is provided inside the box body 1 . One side of the box 1 is provided with a gas inlet 6 and a vacuum outlet 14 , and the other side of the box 1 is provided with a gas outlet 13 and a vacuum inlet 14 . The gas inlet 6 is connected to the compressor 7 through a pipeline, and the gas passing through the compressor 7 is connected to the first buffer tank 8 through the gas filter unit 5, and the buffer tank 8 is connected to the nitrogen generator 18 to generate nitrogen, and the nitrogen passes through After the booster pump 11 is pressurized, it enters the second buffer tank 8 arranged between the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap