Roll-over stand suitable for carbon fiber plate image scanning detection

A carbon fiber board, image scanning technology, applied in measuring devices, optical devices, mechanical devices, etc., can solve the problems of inaccurate models and no image scanners, and achieve the effect of ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or replacement made based on the teachings of the present invention belongs to the protection scope of the present invention.

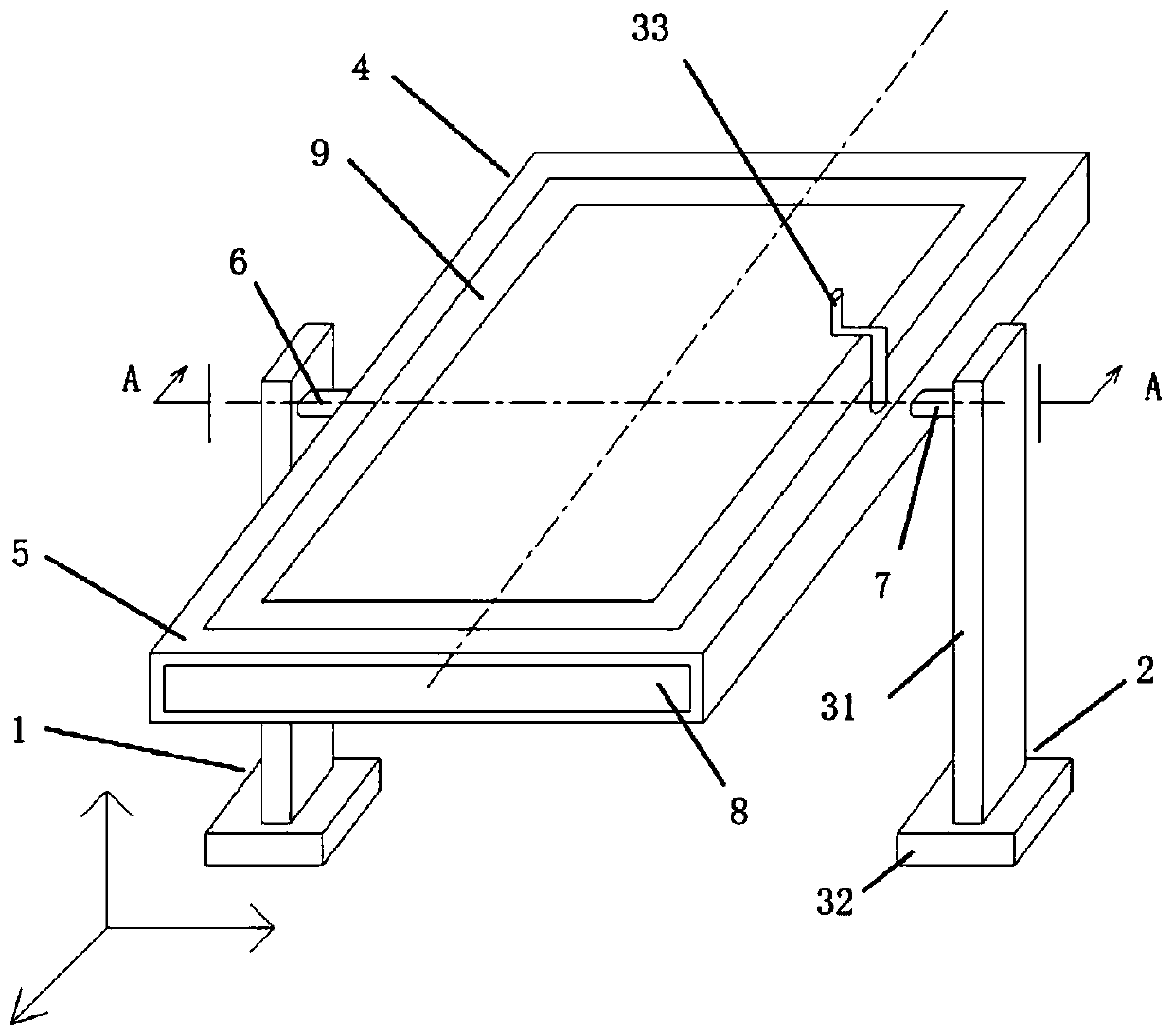

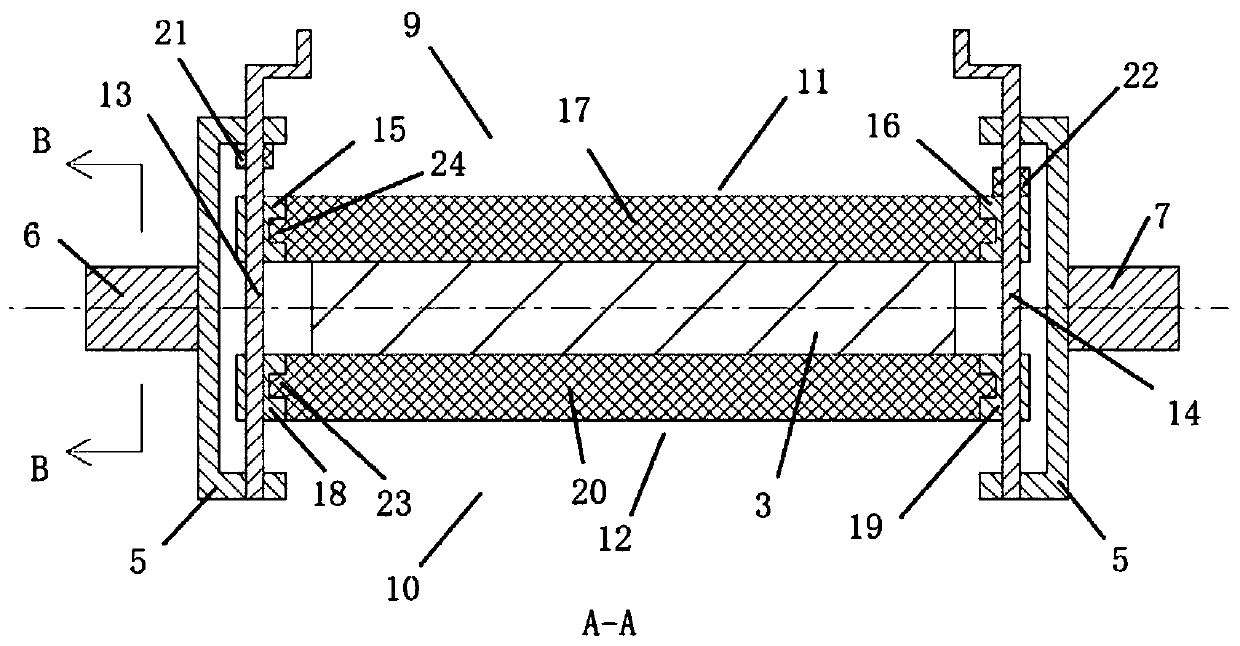

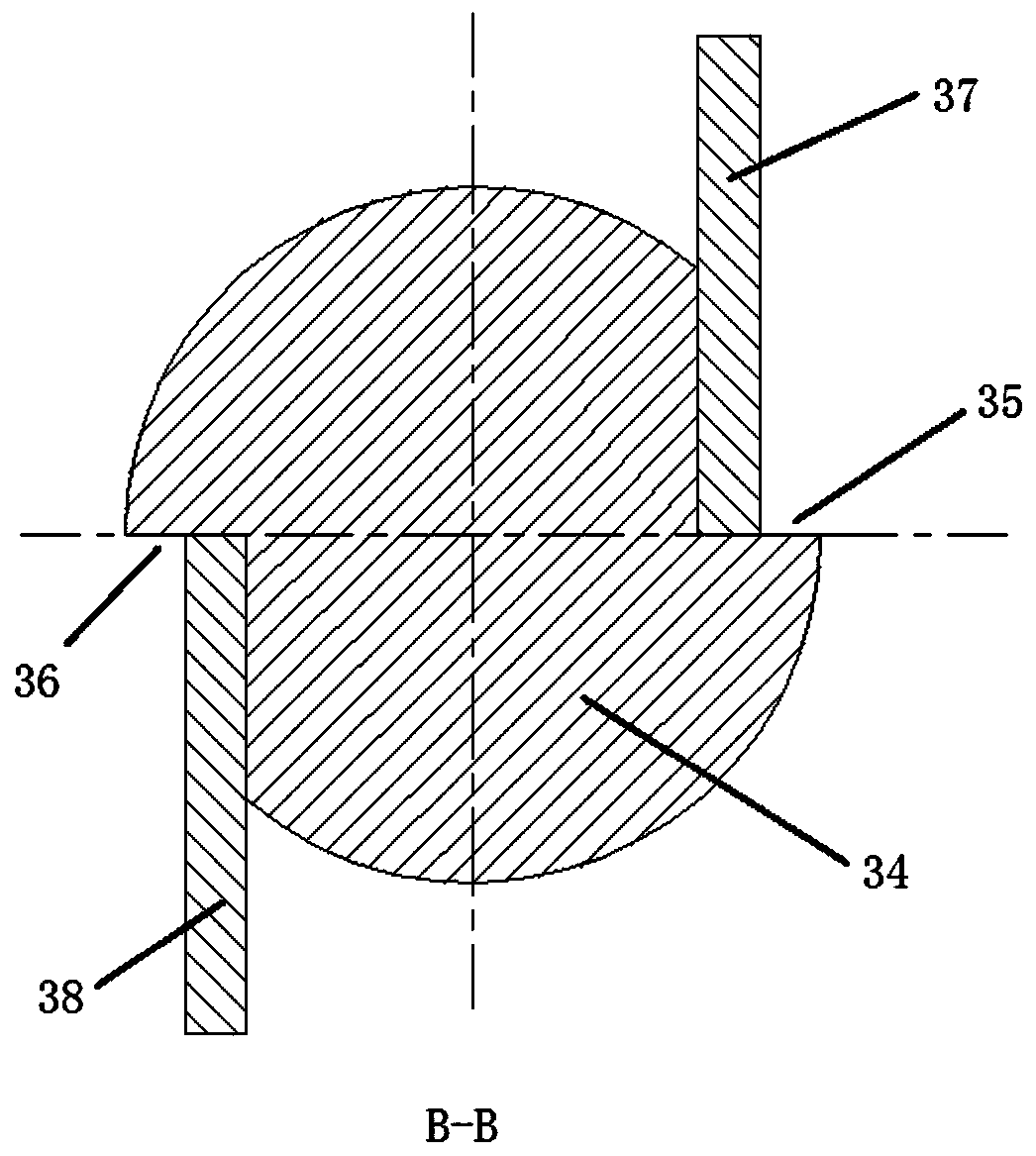

[0030] like Figure 1-5As shown, the flip frame adapted to the carbon fiber plate image scanning detection of the present invention includes a left support frame 1, a right support frame 2 and a flip frame 4, and the flip frame 4 is rotated and arranged on the left support frame 1 and the right shaft 7 through the left shaft 6 and the right shaft 7. In the right support frame 2, the axes of the left rotating shaft 6 and the right rotating shaft 7 coincide, and the turning frame 4 includes an outer frame 5, a left screw shaft 13, a right screw shaft 14, an upper clamping module 11 and a lower clamping module 12, and The frame 5 is provided with an upper opening 9, a lower opening 10 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com