Circuit board manufacturing method

A circuit board manufacturing, circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problem that the accuracy of exposure alignment cannot be reduced, and achieve the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

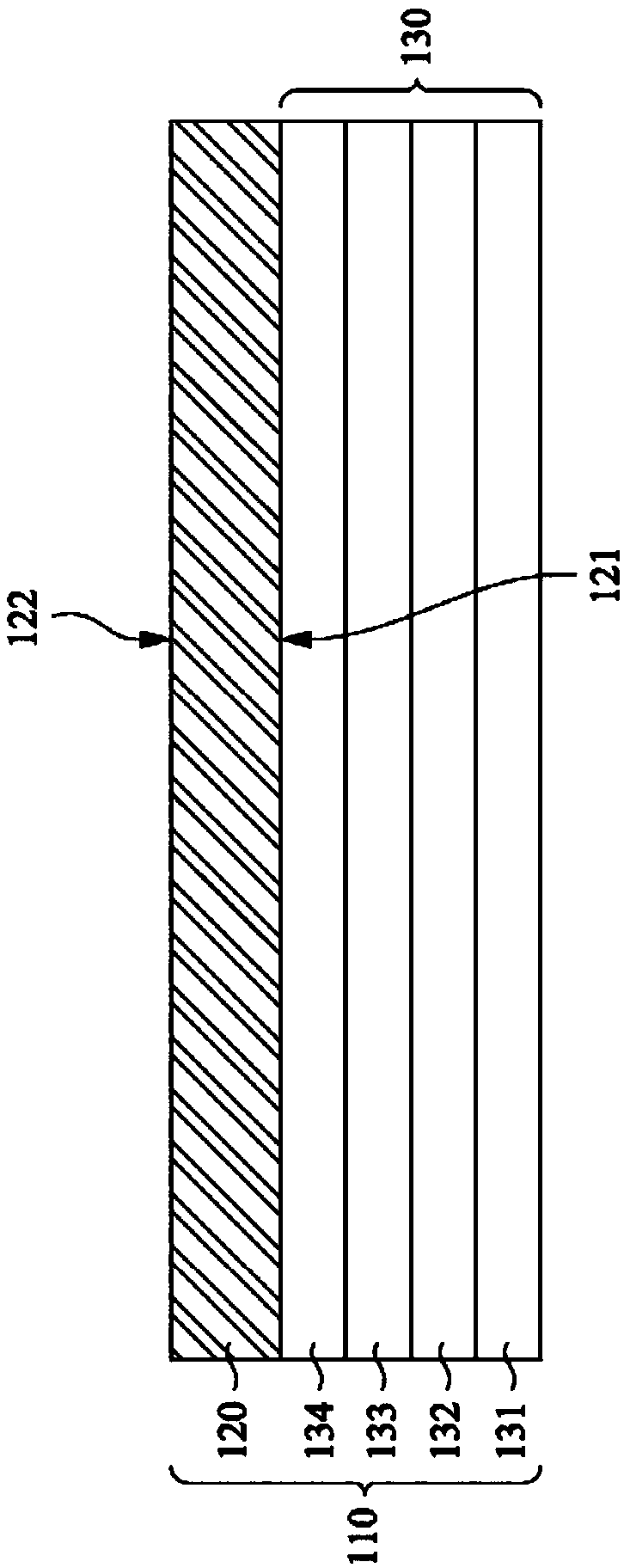

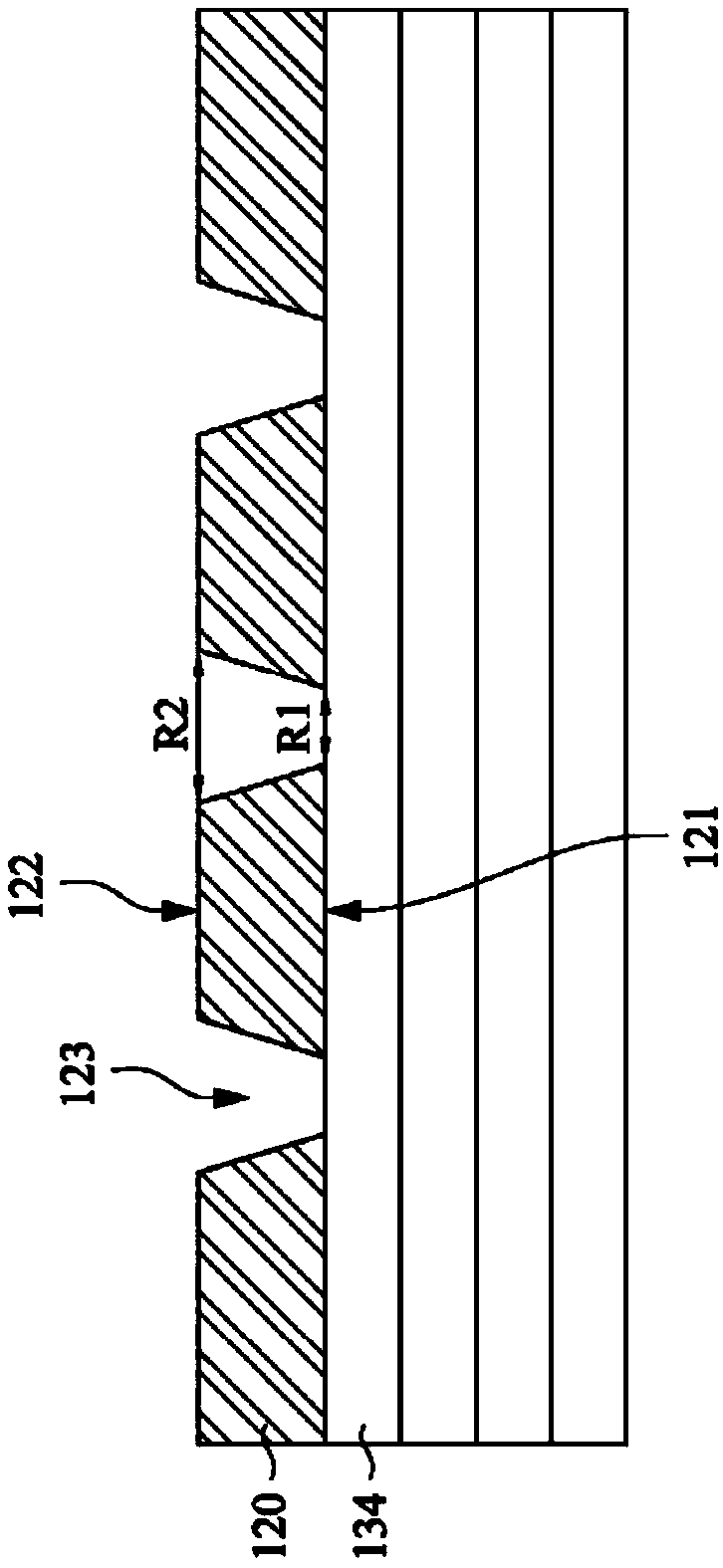

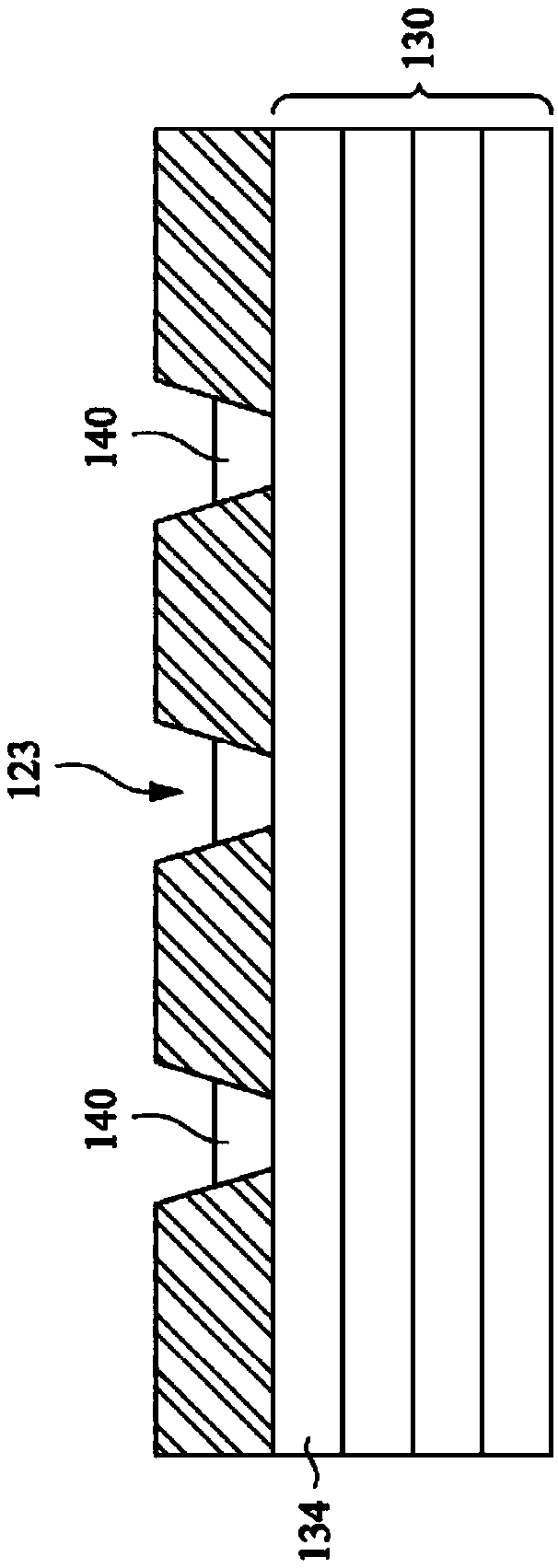

[0017] The invention below provides many different embodiments, or examples, to implement different features of the objects provided. Specific examples of components and arrangements are set forth below for the purpose of simplifying the present disclosure. These are of course only examples and are not intended to be limiting. For example, the dimensions of the device are not limited by the scope or values of the invention, but may depend on the process conditions and / or desired characteristics of the device. In addition, the description that the first feature is formed on or over the second feature includes the embodiment that the first feature and the second feature are in direct contact, and also includes other features formed between the first feature and the second feature, such that the second feature An embodiment in which a first feature is not in direct contact with a second feature. Various features may be arbitrarily shown with different sizes for simplicity and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com