Safe preparation device for oil field water-based fracturing fluid

A safe configuration, oilfield water-based technology, applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problem of affecting the safety of water-based fracturing fluid, uneven base fluid, and affecting the normal oil production To achieve the effect of ensuring safe use, ensuring uniformity and effect, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

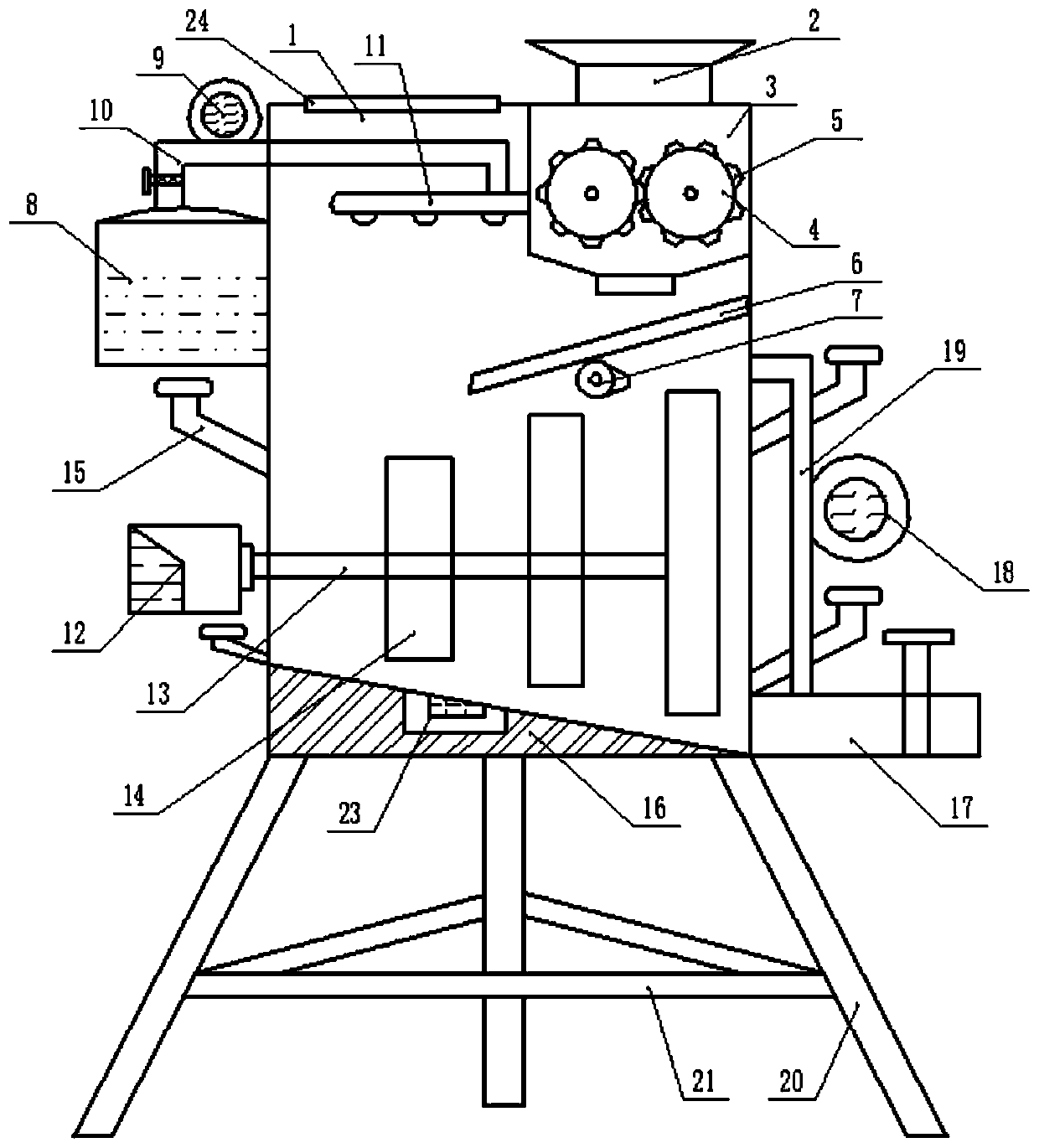

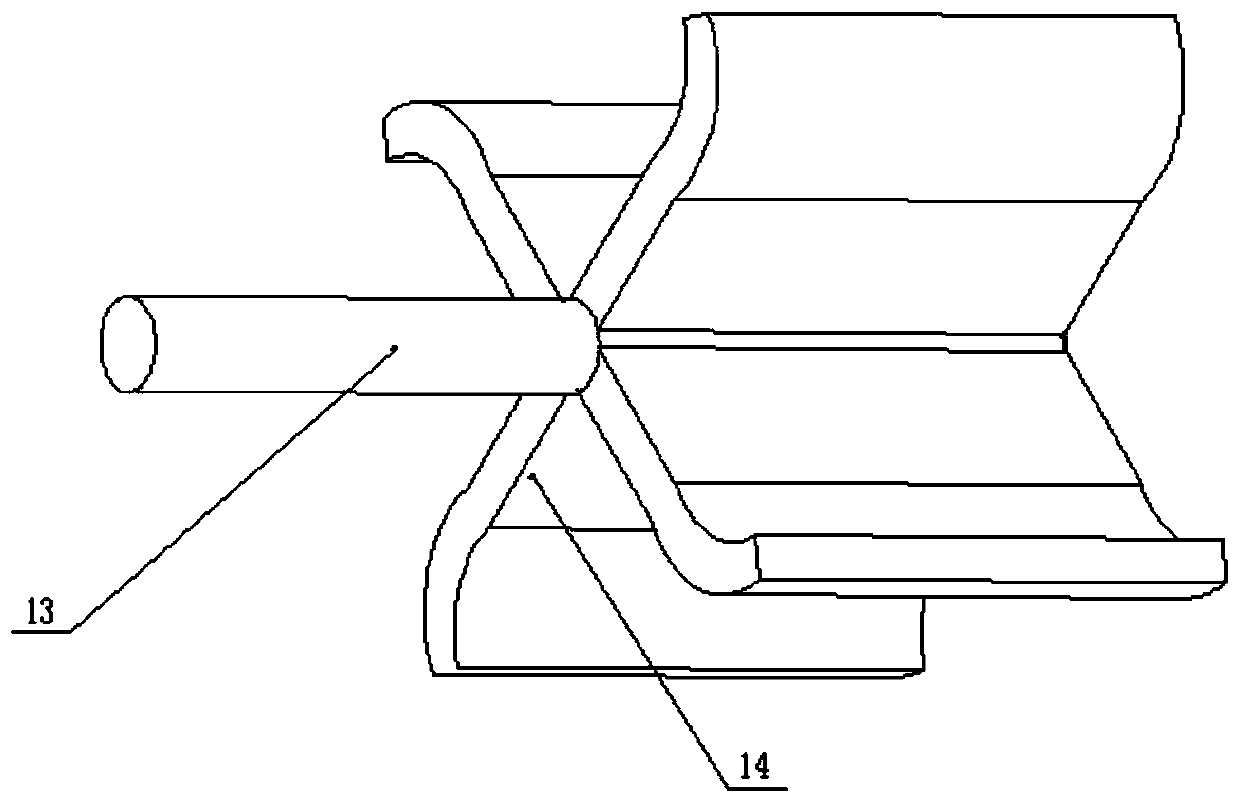

[0020] Example 1: Please refer to Figure 1-3 , an oil field water-based fracturing fluid safety configuration device, comprising a configuration tank 1, the top of the configuration tank 1 is provided with a feed pipe 2, the feed pipe 2 is convenient for inputting raw materials such as guar gum powder particles, and is convenient for subsequent water-based fracturing fluids. The preparation of fracturing fluid is convenient to use.

[0021] There is a crushing box 3 inside the configuration tank 1, and the crushing box 3 is set directly below the feed pipe 2. There are multiple groups of crushing rollers 4 inside the crushing box 3, and the outer wall of the crushing roller 4 is uniformly equipped with rolling teeth 5. 4. The crushing teeth 5 are interlocked and set, and the crushing rollers 4 in the crushing box 3 are rotated to crush and grind each other, so as to prevent the large particles from affecting the preparation of the subsequent water-based fracturing fluid and e...

Embodiment 2

[0029] Embodiment 2: On the basis of Embodiment 1, support legs 20 are provided at the bottom of the configuration tank 1, and a strengthening connecting plate 21 is provided between the supporting legs 20. The strengthening connecting plate 21 and the supporting legs 20 ensure the stability of the device, which is beneficial to the on-site configuration of water. The base fracturing fluid is convenient for normal oil extraction and easy to use.

[0030] The top of the dispensing tank 1 is provided with a transparent observation window 24, which is convenient for people to clearly observe the preparation situation inside the device, which is beneficial to use.

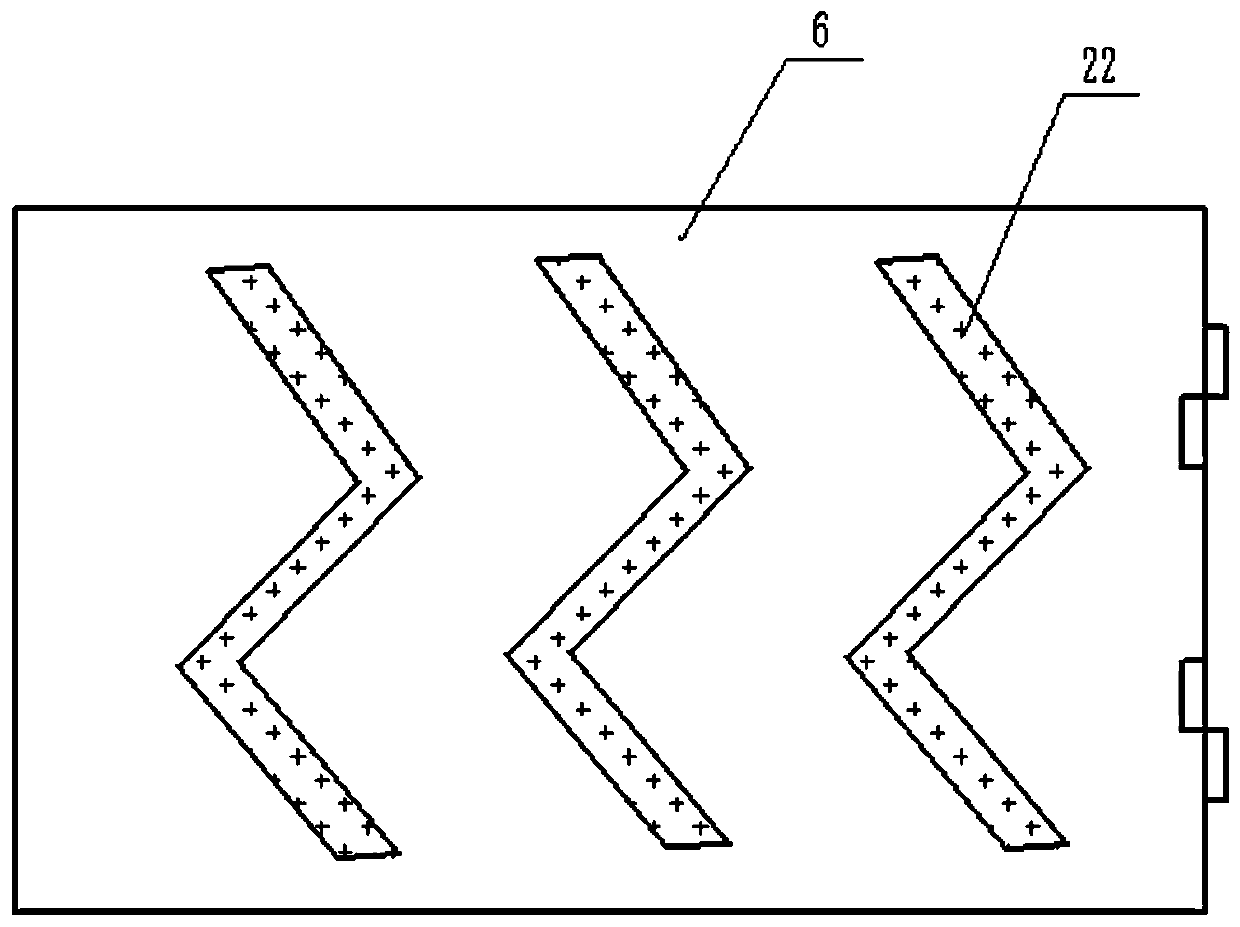

[0031] The shaker plate 6 is uniformly provided with a fold-shaped deceleration corrugator 22, which reduces the speed of falling of raw materials such as guar gum powder particles, ensures the uniform input of raw materials, facilitates the preparation of subsequent water-based fracturing fluids, and is beneficial to u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com