Bending machining method for duplex turbine blade locking plate

A turbine blade and bending processing technology, applied in the aerospace field, can solve the problems of high mold production cost, high product failure rate, short mold service cycle, etc., and achieve the effect of stable processing, good surface quality and good product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for bending a double-connected turbine blade locking piece, comprising the following steps:

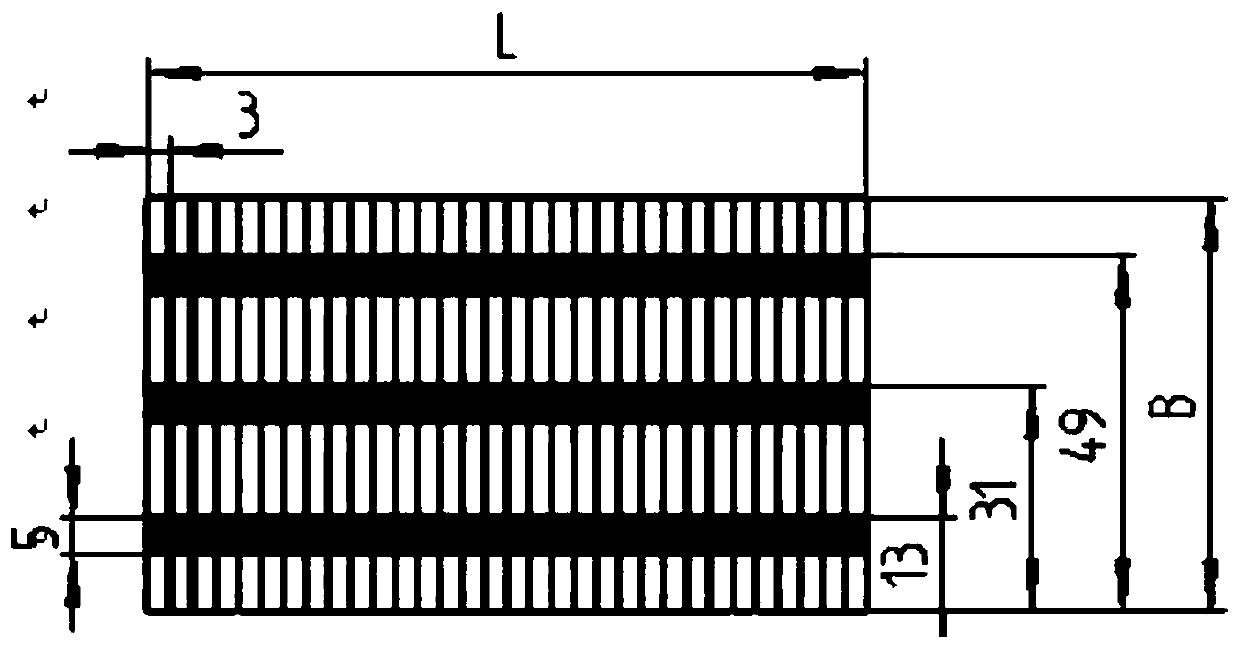

[0026] 1) Choose two 1.5mm thick stainless steel sheets, according to the corresponding width B × length L, and mark the direction of the metal flow line, and ensure the overall length requirements; see figure 2 ;

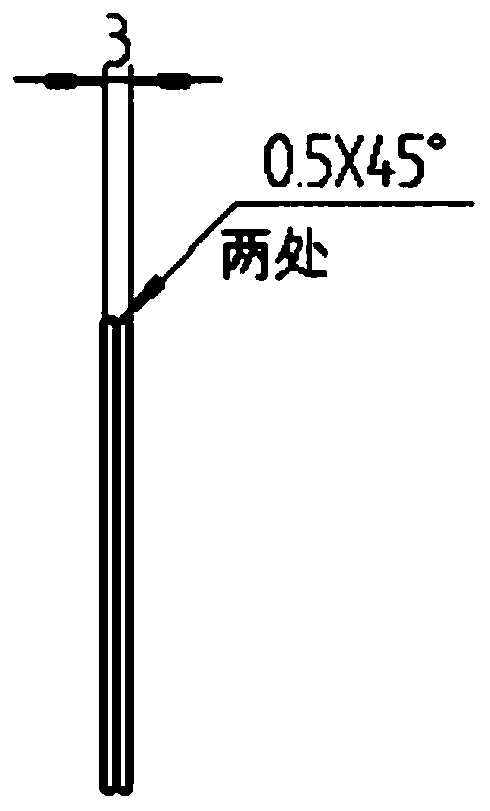

[0027] 2) Invert the upper and lower ports of the joints of the two boards by C0.5, then carry out seam welding, and adjust the position and size of the corresponding rollers to meet the requirements;

[0028] 3) Carry out wire cutting along the direction of the metal flow line to obtain the desired length and width of the double turbine blade lock

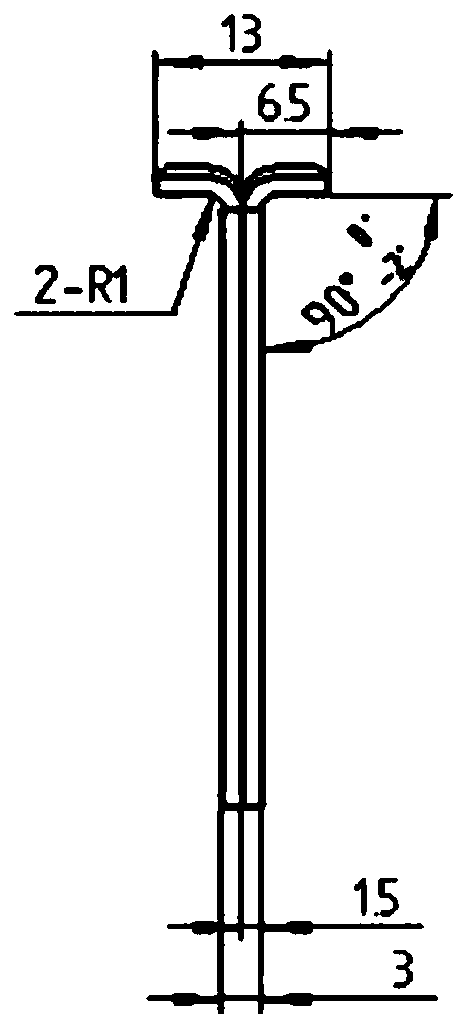

[0029] 4) Pre-bending the head of the lock plate of the turbine blade for the fitter opening; see Figure 4 ;

[0030] 5) Based on the other end, place the processed pre-bent part in the lower mold of the bending mold, and perform final bending and forming processing on the pre-bending part of the head to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com