Yarn motion parameter identification method and device, readable storage medium and system

A technology of motion parameters and recognition methods, which is applied in the direction of measuring devices, manufacturing computing systems, image data processing, etc., can solve the problems of recognition accuracy and the influence of far and near objects, and achieve the effects of optimizing accuracy, precise positioning, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

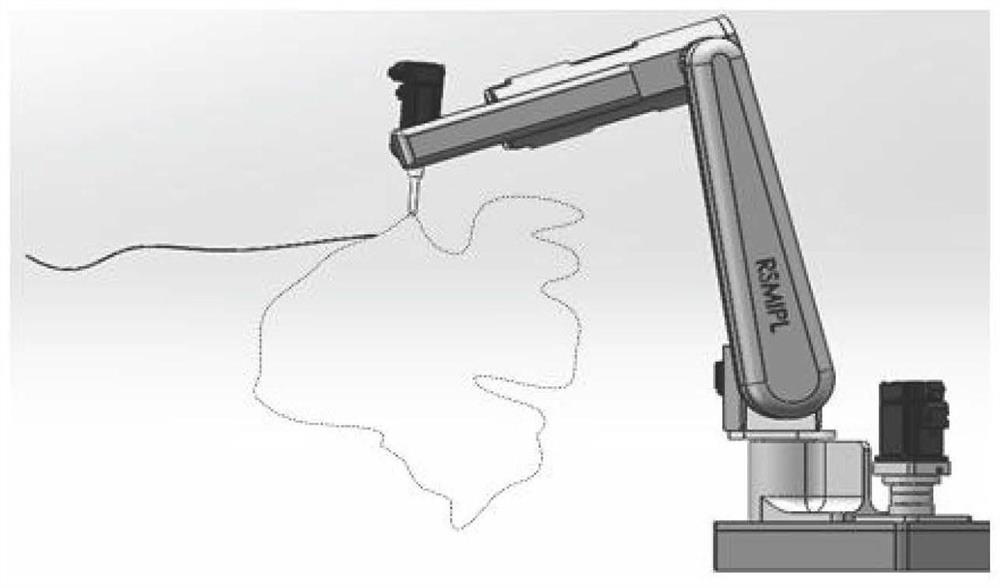

[0179] Such as Figure 7 As shown, a yarn motion parameter identification system is used for non-contact measurement of yarn running on production equipment in the textile production process to obtain yarn motion parameters. The system includes: an image acquisition device 1, a computer 2;

[0180] The image acquisition device 1 includes: a binocular high-speed camera 11, an adjustment platform 12, and a bracket 13, which are used to acquire a sequence of yarn image pairs when the yarn is moving;

[0181] The bracket 13 at least includes: a vibration isolator 131, a bracket foot 132, and a central column 133;

[0182] The vibration isolator 131 is arranged at the end of the foot part 132 of the bracket, and is used to shield the influence of external vibration on the image acquisition device 1;

[0183] The central post 133 is slidably connected to the support foot 132;

[0184] The adjustment platform 12 is set on the top of the central column 133;

[0185] The binocular hi...

Embodiment 2

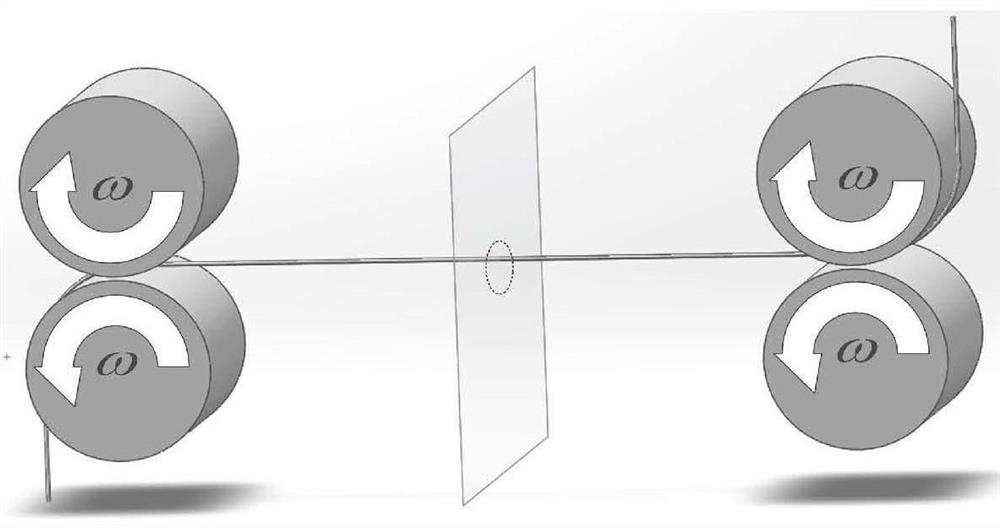

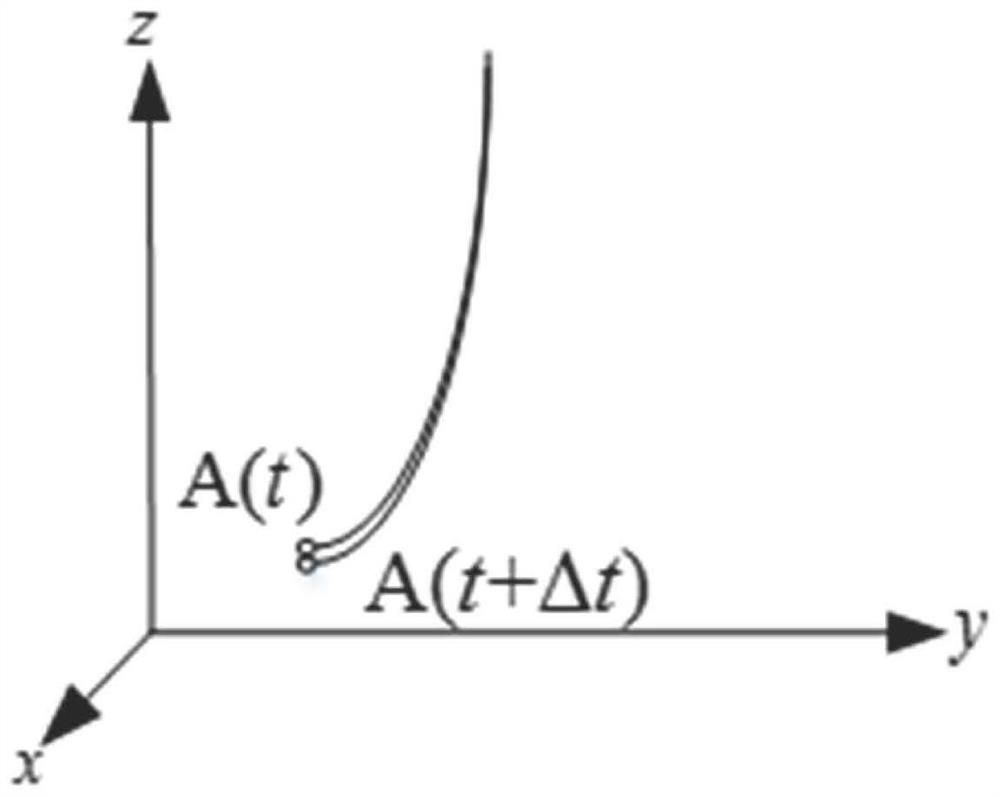

[0190] This embodiment verifies the high accuracy of identifying the motion parameters of the yarn in the first state by using a yarn motion parameter identification method. Using the image acquisition device described in Embodiment 1, the motion parameters of the yarn end points are identified. Such as Figure 8 As shown, the hook 41 is arranged on the top of the system for fixing one end of the yarn 9; the electromagnetic clip 42 and the hook 41 are arranged at the same horizontal position; When the power supply 43 supplies energy, the electromagnetic clip 42 clamps and fixes the other end of the yarn 9; Movement around the hook 41;

[0191] The motor 44 is arranged directly below the hook 41, and the rotating shaft of the hook 41 and the motor 44 is on the same straight line; the rotating shaft of the motor 44 is connected with the right-angle workpiece 45 through a coupling; the right-angle workpiece 45 is driven by the motor 44 around the The rotating shaft makes a cir...

Embodiment 3

[0227] Winding machine 3 is the equipment with the most complex structure in the yarn production equipment, which can simultaneously drive 8 to 12 packages to rotate synchronously for winding, such as Figure 13 shown. The traversing device 312 is used to drive the yarn to reciprocate in the horizontal direction to guide the yarn. In order to stabilize the position of the yarn just wound on the surface of the package, the system is provided with a pressing roller 313 which is in contact with the surface of the package. In order to keep the winding line speed constant, the spindle shaft 314 rotating speed gradually decreases from the highest 18000r / min to the lowest 4500r / min with the increase of the package diameter, while the rotating speed of the pressure roller 313 is kept at 29000r / min.

[0228] Winder unit 31 ( Figure 14 The illustrated enlarged structural unit of the winding machine 3) at least includes: a guide wire hook 311, a traverse device 312, a pressing roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com