Steel bar corrosion inhibitor for marine concrete and preparation method thereof

A steel rust inhibitor and marine concrete technology, applied in the field of building materials, can solve problems such as failure and performance degradation of reinforced concrete structural materials, and achieve the effects of reducing chlorine content, increasing steel corrosion resistance, and improving protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

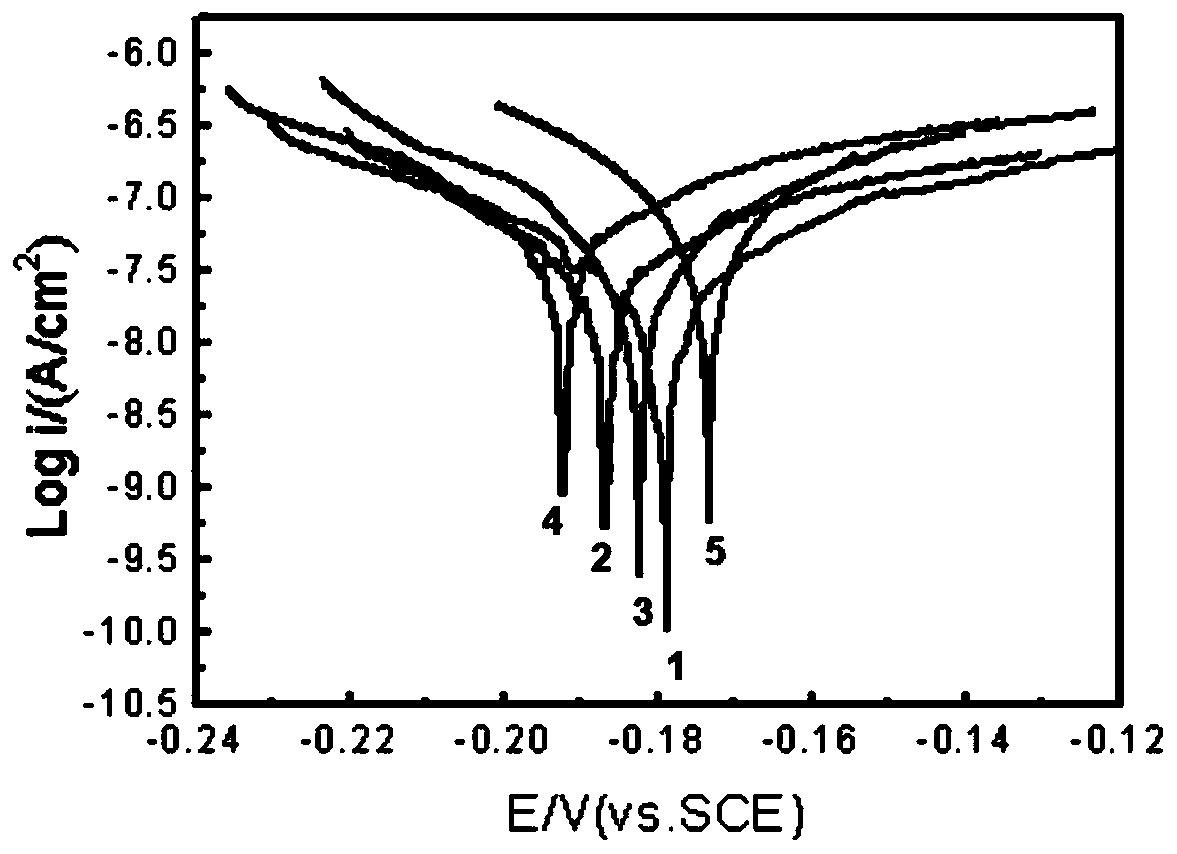

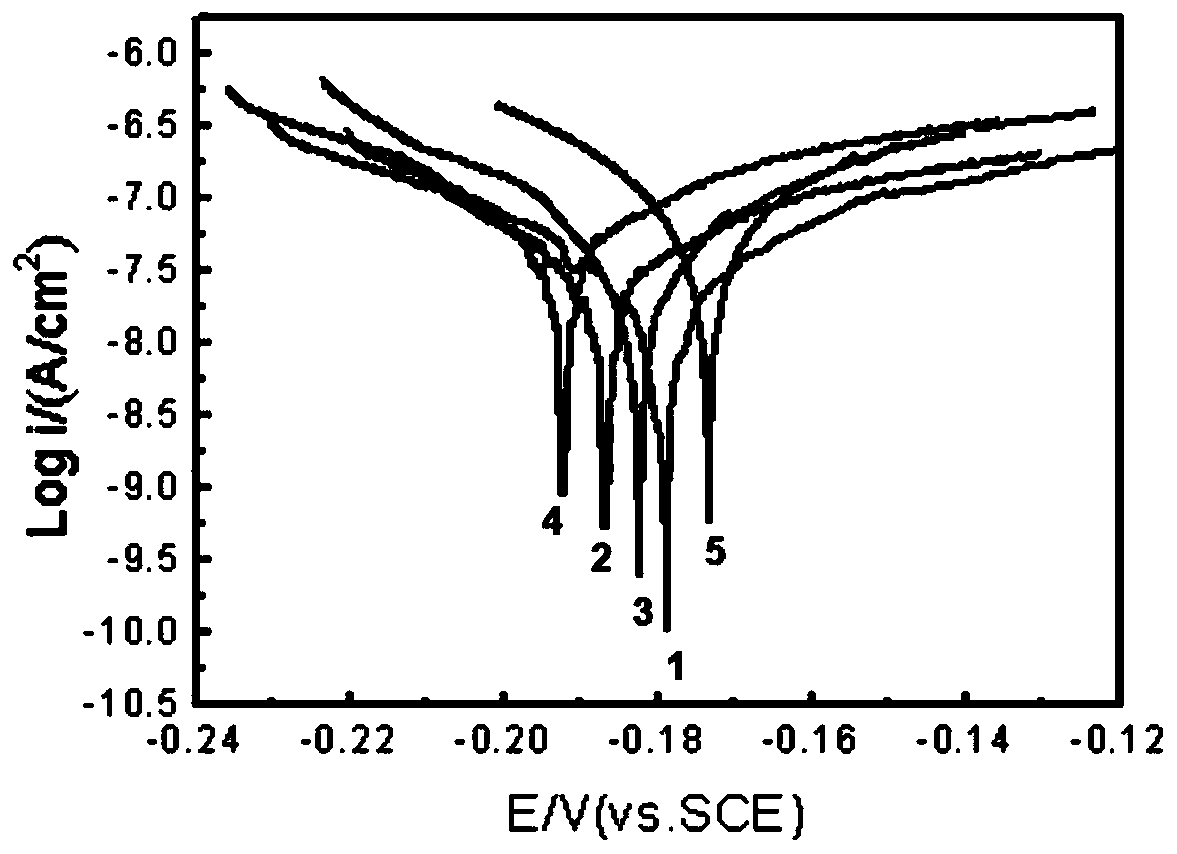

Image

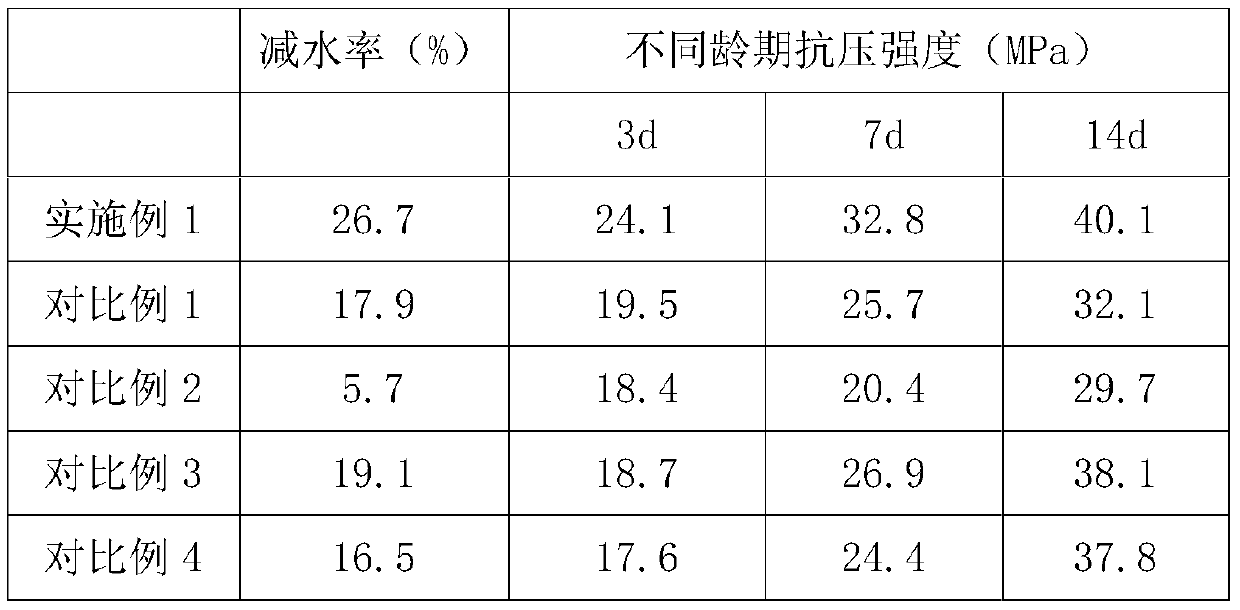

Examples

Embodiment 1

[0026] A steel rust inhibitor for marine concrete, comprising 40 parts of N, N-dimethylethanolamine, 25 parts of polycarboxylic acid terpolymer, 7 parts of 2-phenylimidazoline quaternary ammonium salt by weight parts , 12 parts of hydroxide, 2 parts of water-based polyaniline, 3 parts of polyol phosphate, 50 parts of water, the pH is 12.7. The preparation method comprises the following steps: (1) adding water into a container, heating to 45° C., adding N,N-dimethylethanolamine, 2-phenylimidazoline quaternary ammonium salt, and water-based polyaniline in sequence, and stirring for 5 minutes; (2) Continue heating to 60° C., add polyol phosphate and polycarboxylic acid terpolymer again and stir for 5 minutes, and finally add hydroxide to adjust the pH value.

Embodiment 2

[0028] A steel rust inhibitor for marine concrete, comprising 50 parts of N, N-dimethylethanolamine, 30 parts of polycarboxylic acid terpolymer, 10 parts of 2-phenylimidazoline quaternary ammonium salt by weight parts , 15 parts of hydroxide, 5 parts of water-based polyaniline, 5 parts of polyol phosphate, 60 parts of water, the pH is 12.4. The preparation method comprises the following steps: (1) adding water into a container, heating to 50° C., adding N,N-dimethylethanolamine, 2-phenylimidazoline quaternary ammonium salt, and water-based polyaniline in sequence, and stirring for 5 minutes; (2) Continue heating to 65° C., add polyol phosphate and polycarboxylic acid terpolymer again and stir for 5 minutes, and finally add hydroxide to adjust the pH value.

Embodiment 3

[0030] A steel rust inhibitor for marine concrete, comprising 30 parts of N, N-dimethylethanolamine, 20 parts of polycarboxylic acid terpolymer, 5 parts of 2-phenylimidazoline quaternary ammonium salt by weight parts , 10 parts of hydroxide, 1 part of water-based polyaniline, 3 parts of polyol phosphate, 40 parts of water, the pH is 12.2. The preparation method comprises the following steps: (1) adding water into a container, heating to 40° C., adding N,N-dimethylethanolamine, 2-phenylimidazoline quaternary ammonium salt, and water-based polyaniline in sequence, and stirring for 5 minutes; (2) Continue heating to 60° C., add polyol phosphate and polycarboxylic acid terpolymer again and stir for 6 minutes, and finally add hydroxide to adjust the pH value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com