Equipment for performing drawing and bundling by using annular single-silkworm silk

A ring-shaped and equipment-based technology, which is applied in the production of silk from cocoons, transportation of filamentous materials, sustainable manufacturing/processing, etc., can solve the problems of low added value, large unevenness, and high labor intensity, and achieve easy control and structure Novel, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

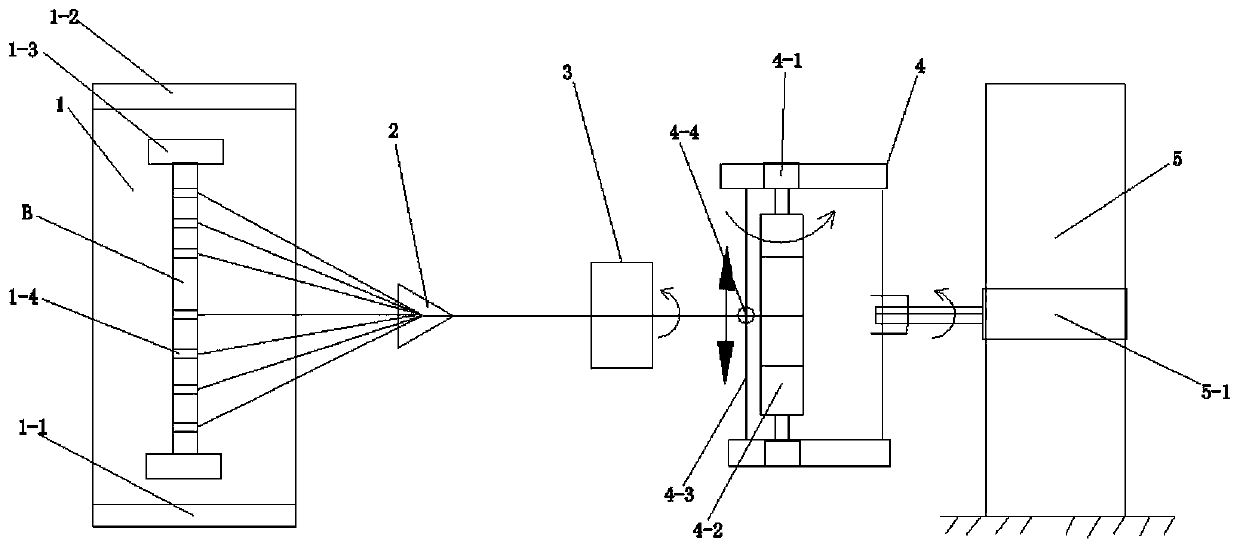

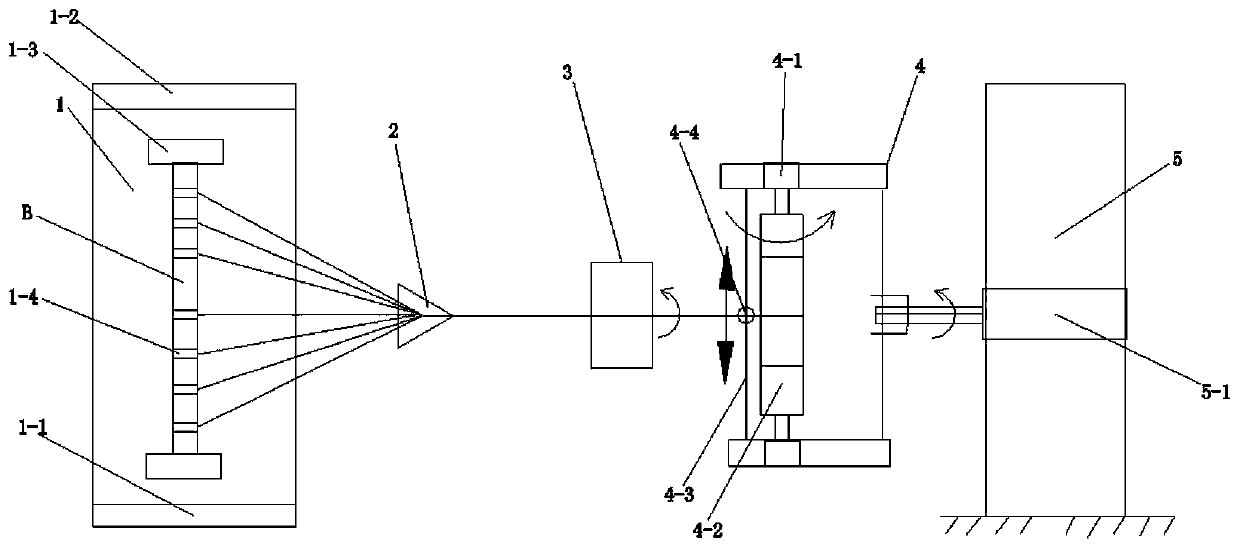

[0019] The technical scheme adopted by the present invention to solve the technical problem is: a device that utilizes single silkworm to spit out ring-shaped silk for spinning and bunching. 3. Rotary wire winding device 4, headstock 5.

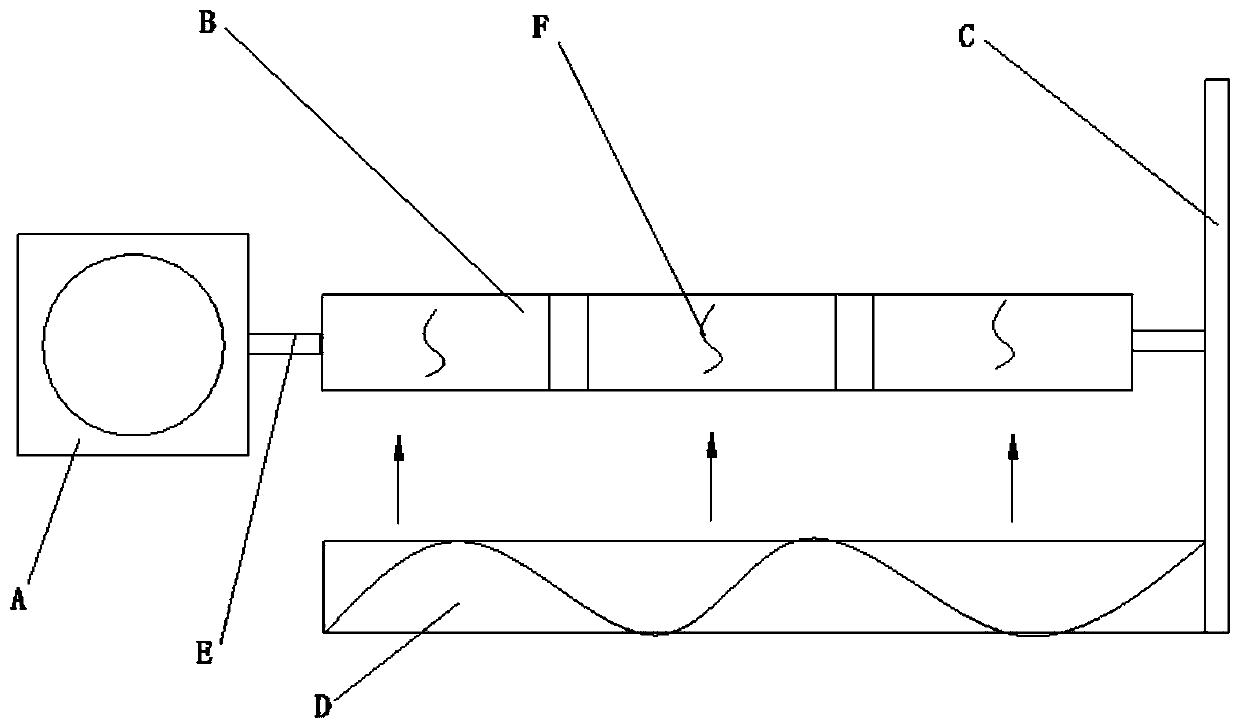

[0020] The two ends of the ring-shaped wire unwinding device 1 are respectively fixed with an ultrasonic oscillator 1-1 and a heater 1-2, and the ring-shaped wire forming roller B is placed on the ring-shaped wire forming roller fixing seat 1-3. The silk generating roller fixing seat 1-3 is fixedly installed in the ring-shaped silk unwinding device 1.

[0021] The headstock 5 is fixedly equipped with a variable frequency motor 5-1, and the variable frequency motor 5-1 is connected with the rotating wire winding device 4 through a crankshaft.

[0022] Described rotary wire winding device 4 can rotate under the drive of variable frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com