Multi-frequency resistivity measuring device

A measuring device and resistivity technology, applied in electrical/magnetic detection for well logging records, wellbore/well components, earthwork drilling and production, etc., to achieve excellent efficiency, energy saving and consumption reduction, simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

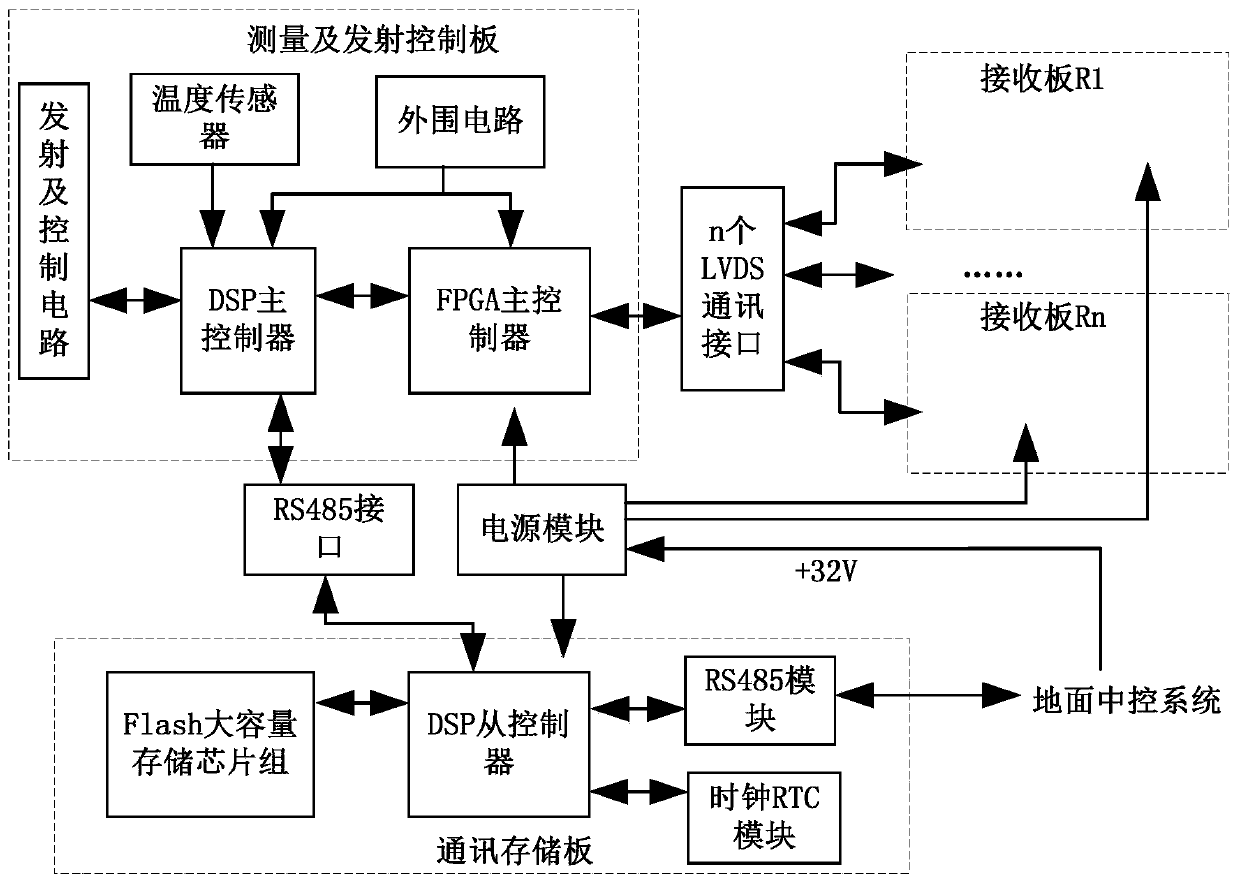

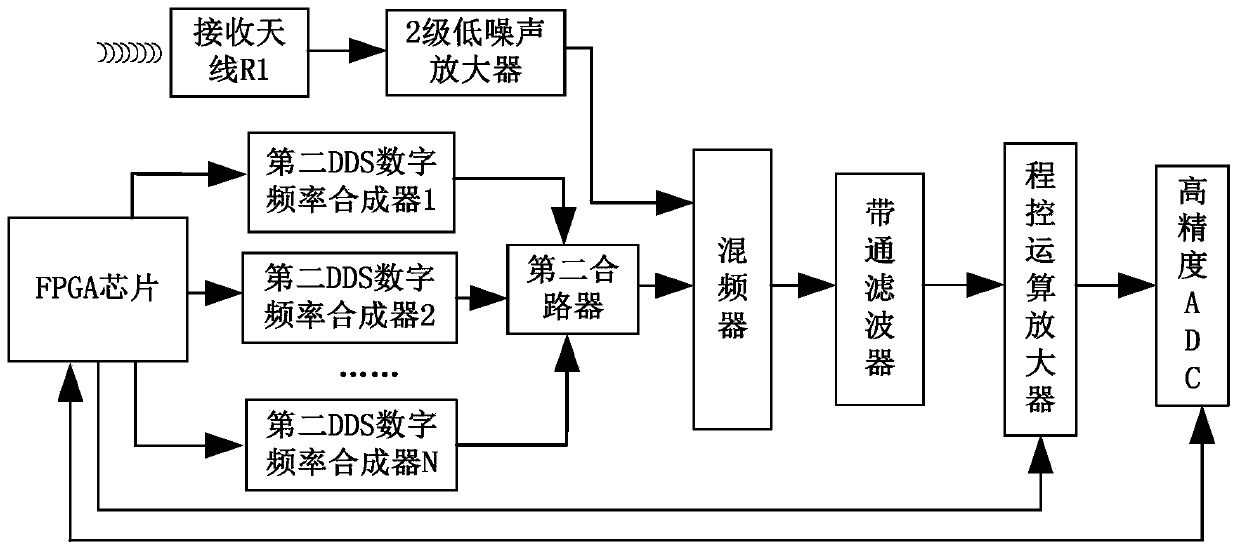

[0028] Embodiments of the present invention provide a multi-frequency resistivity measuring device, such as figure 1As shown, it includes a measurement and emission control board, a power module, a communication storage board and n receiving boards. The measurement and emission control board is respectively connected to n receiving boards through n LVDS communication interfaces. The RS485 interface is connected to the communication storage board, the input terminal of the power module is connected to the ground central control system, and its output terminal is respectively connected to the measurement and emission control board, the communication storage board and each receiving board, and the communication storage board is also connected to the ground central control system connect.

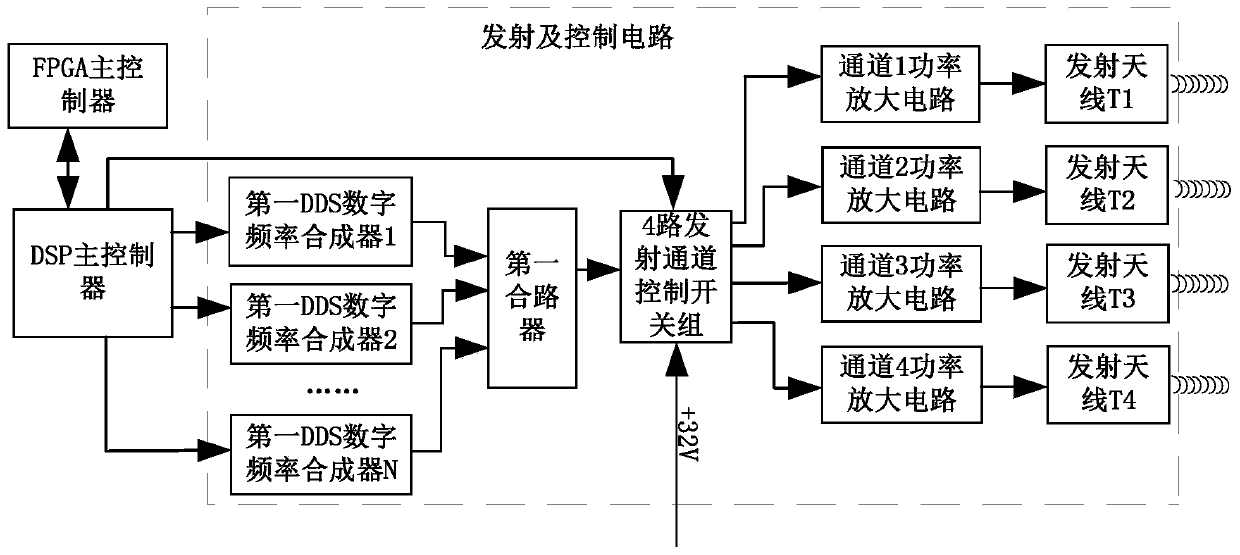

[0029] The measurement and emission control board includes FPGA main controller, DSP main controller, emission and control circuit, temperature sensor and peripheral circuit.

[0030] The DSP ...

Embodiment 2

[0065] A multi-frequency resistivity measurement method such as Figure 5 As shown, the following steps S1-S13 are included:

[0066] S1. Power on the multi-frequency resistivity measuring device, and perform initialization and self-test.

[0067] S2. Put the multi-frequency resistivity measuring device on standby, and wait for receiving instructions.

[0068] S3. Judging whether the received instruction is an instruction to start measurement, if so, proceed to step S4, otherwise perform related operations according to the instruction requirements, and return to step S2.

[0069] In the embodiment of the present invention, related operations include instrument status query, memory data reading, Flash formatting and parameter configuration.

[0070] S4. Enable multiple first DDS digital frequency synthesizers to generate different frequency transmitting signals through the DSP main controller on the measuring and transmitting control board, and integrate multiple transmitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com