Contour data processing method based on sliding window mean filtering

A mean filtering and sliding window technology, applied in image data processing, measuring devices, instruments, etc., can solve problems such as loss of details, image distortion, random noise in the process of extracting large and complex surface contours, and achieve small standard deviation and variance, Accurate elimination, simple and efficient measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

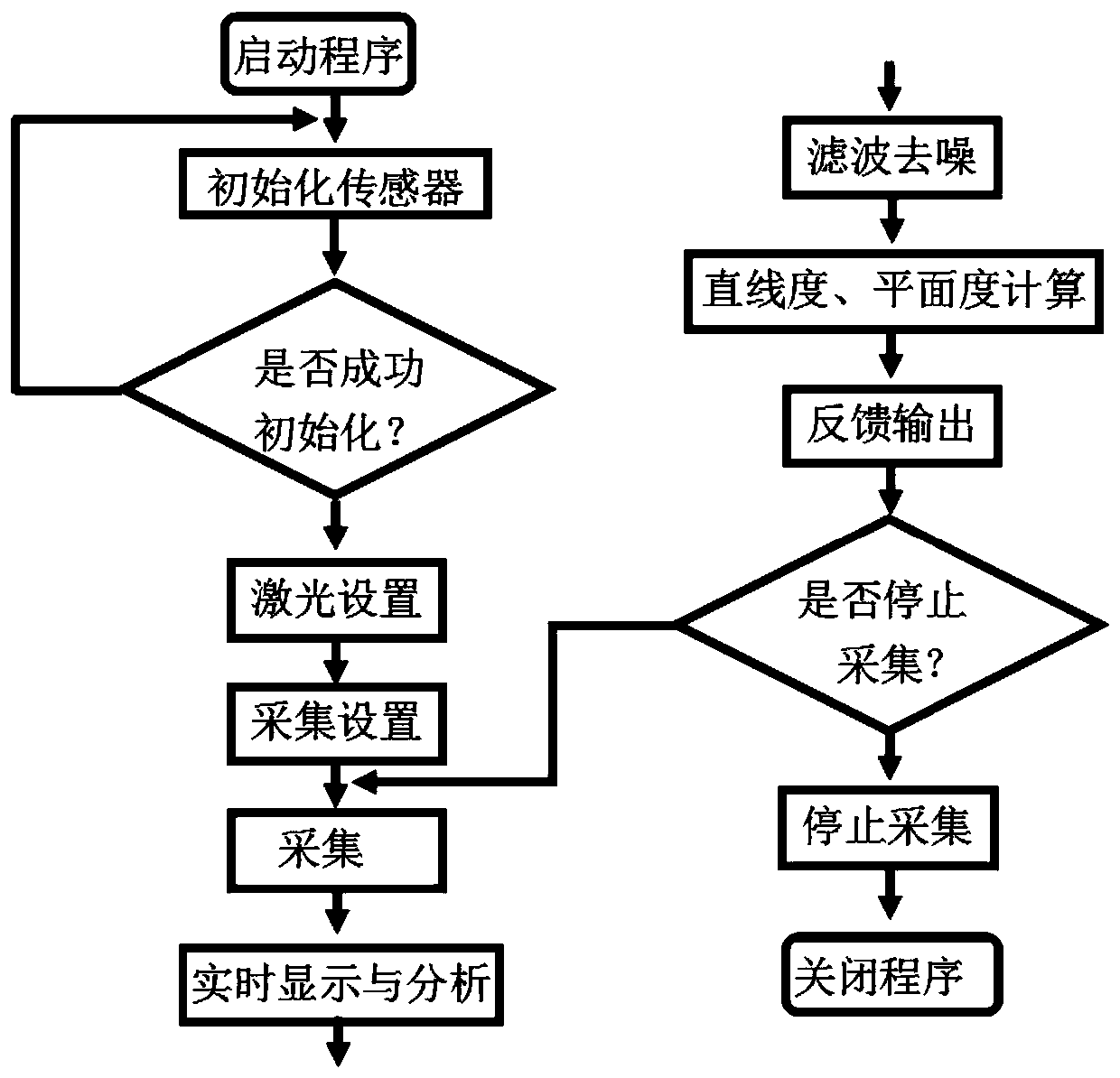

[0042] Specific embodiment one: a kind of contour data processing method based on sliding window mean filter of the present embodiment, it is carried out according to the following steps:

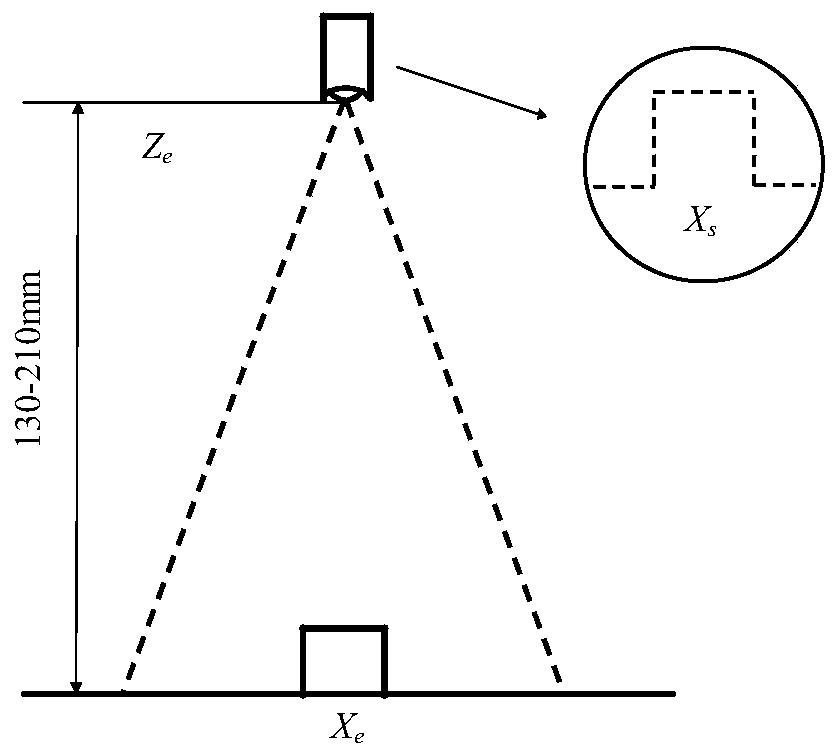

[0043] Step 1: Before measuring the contour of the profile, the laser vision sensor is first calibrated, and the two-dimensional pixel image of the computer is restored to the earth coordinates;

[0044] Step 2: Rigidly fix the laser vision sensor and the motion system to ensure that the sensor is always in the common working range during the movement;

[0045] Step 3: establish the communication between the laser vision sensor and the PC control machine, set the sensor parameters, and set the motion system parameters;

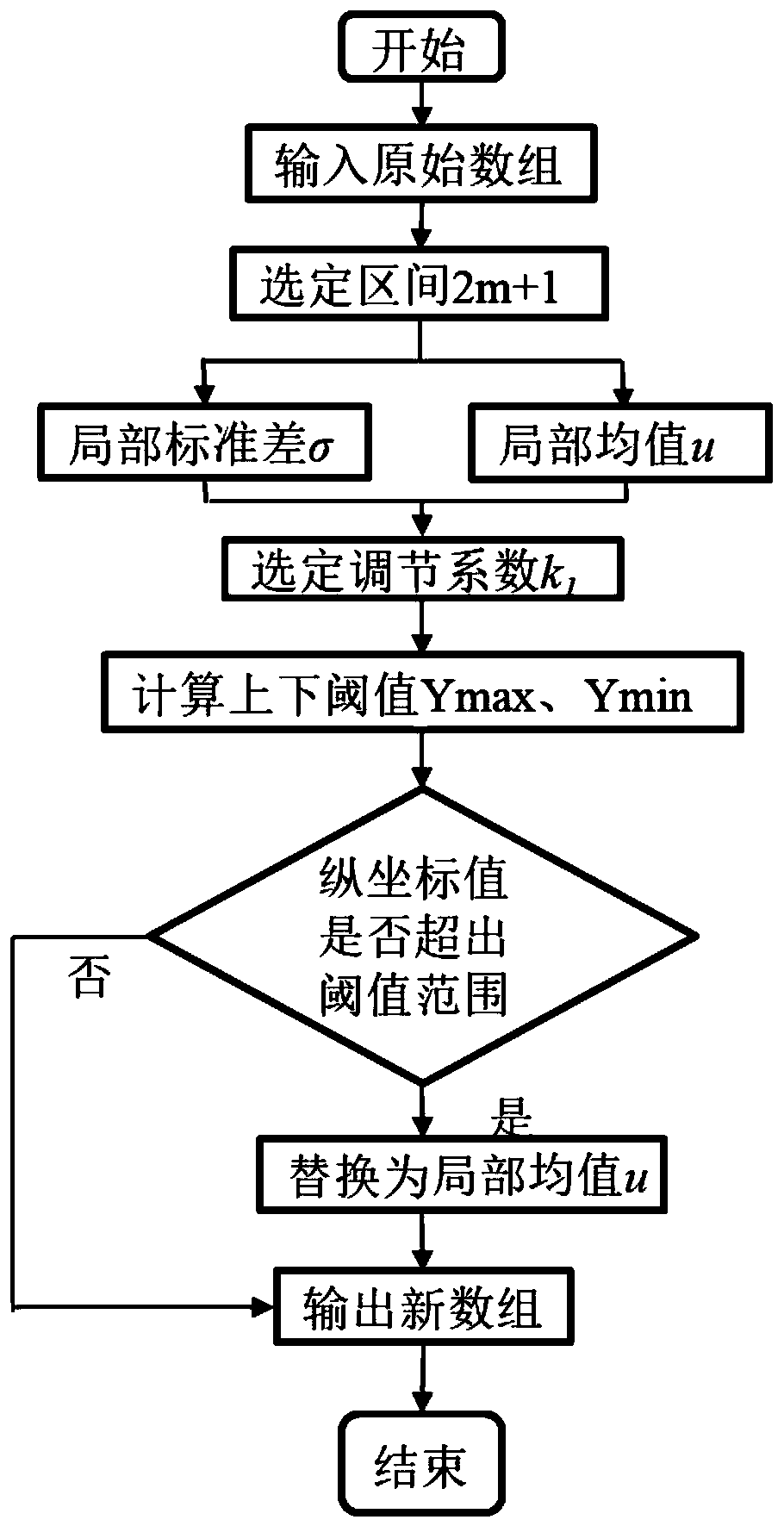

[0046] Step 4: Scan the contour image of the workpiece surface to be measured by the image scanning unit, and each scan obtains an array of 512 points, the abscissa range is 0-511, the ordinate range is 0-1023, and the point array is in order according to the abscissa Arra...

specific Embodiment approach 2

[0059] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the laser vision sensor is a linear laser sensor. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0060] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the linear laser sensor is a scanning laser vision sensor or a structured light vision sensor. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com