Intelligent container terminal system and method based on flexible allocation of storage space

A storage space and terminal system technology, applied in the field of automated storage terminals, can solve the problems of inability to flexibly adjust the unit storage space, reduce the utilization rate of container space, and single size of the unit cabinet, and achieve high promotion and application value and social significance. Container space utilization, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

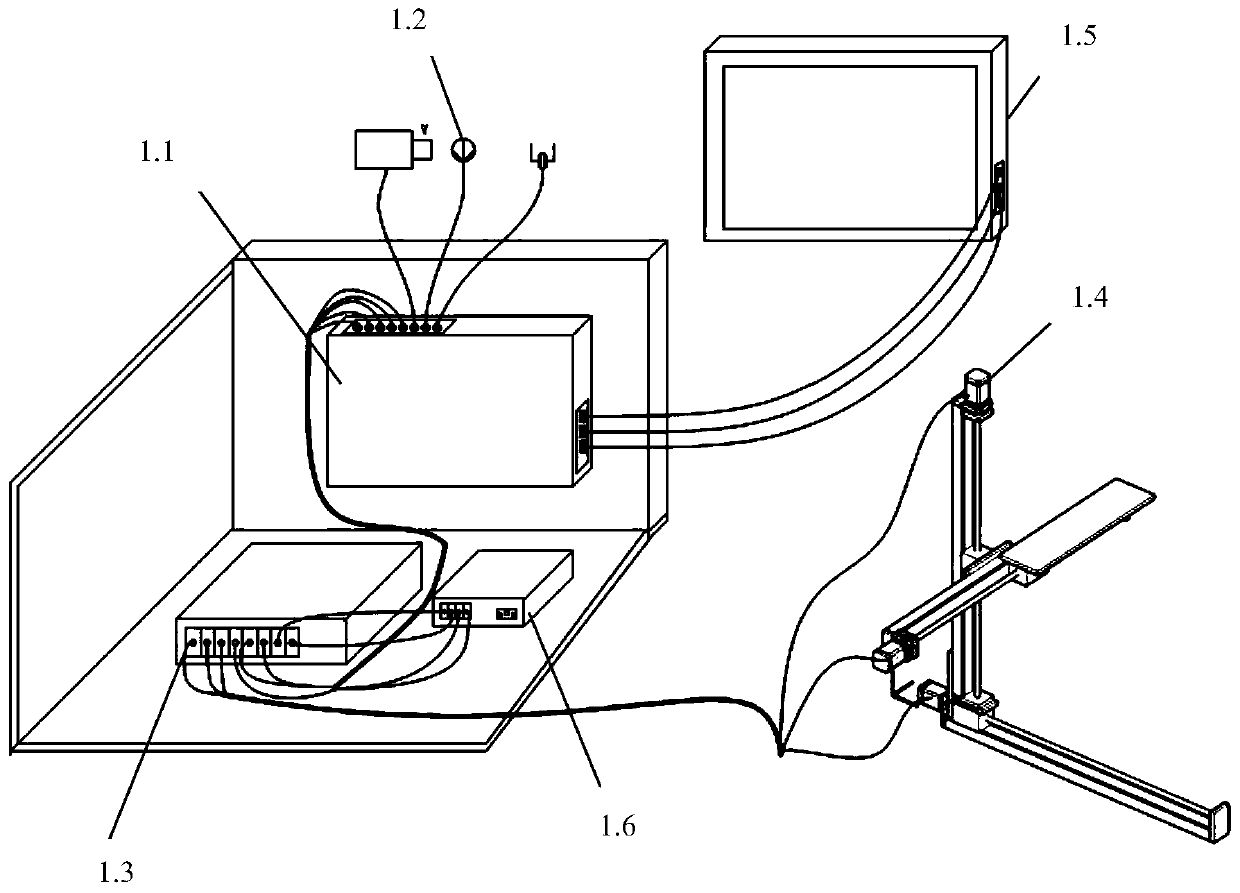

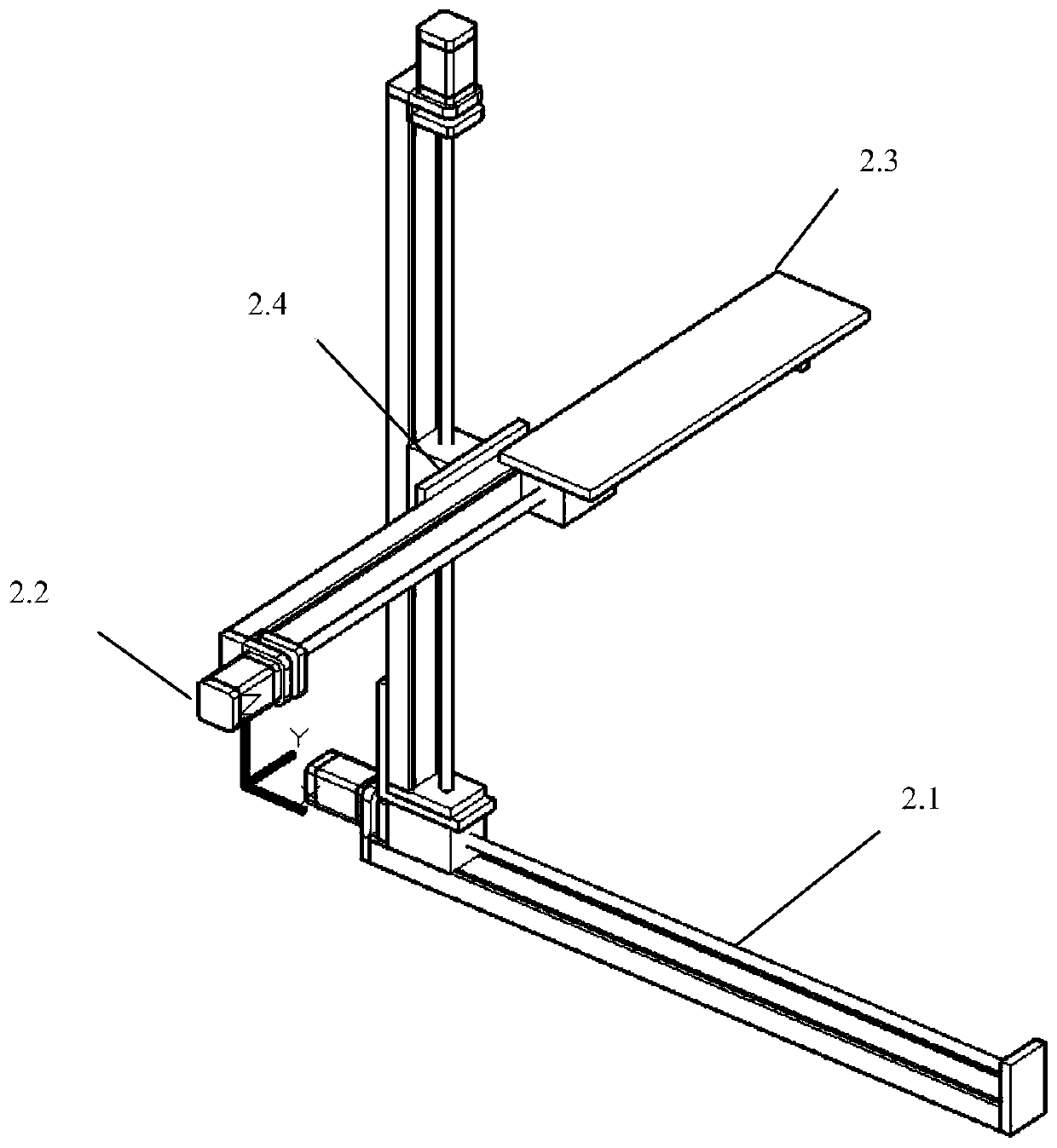

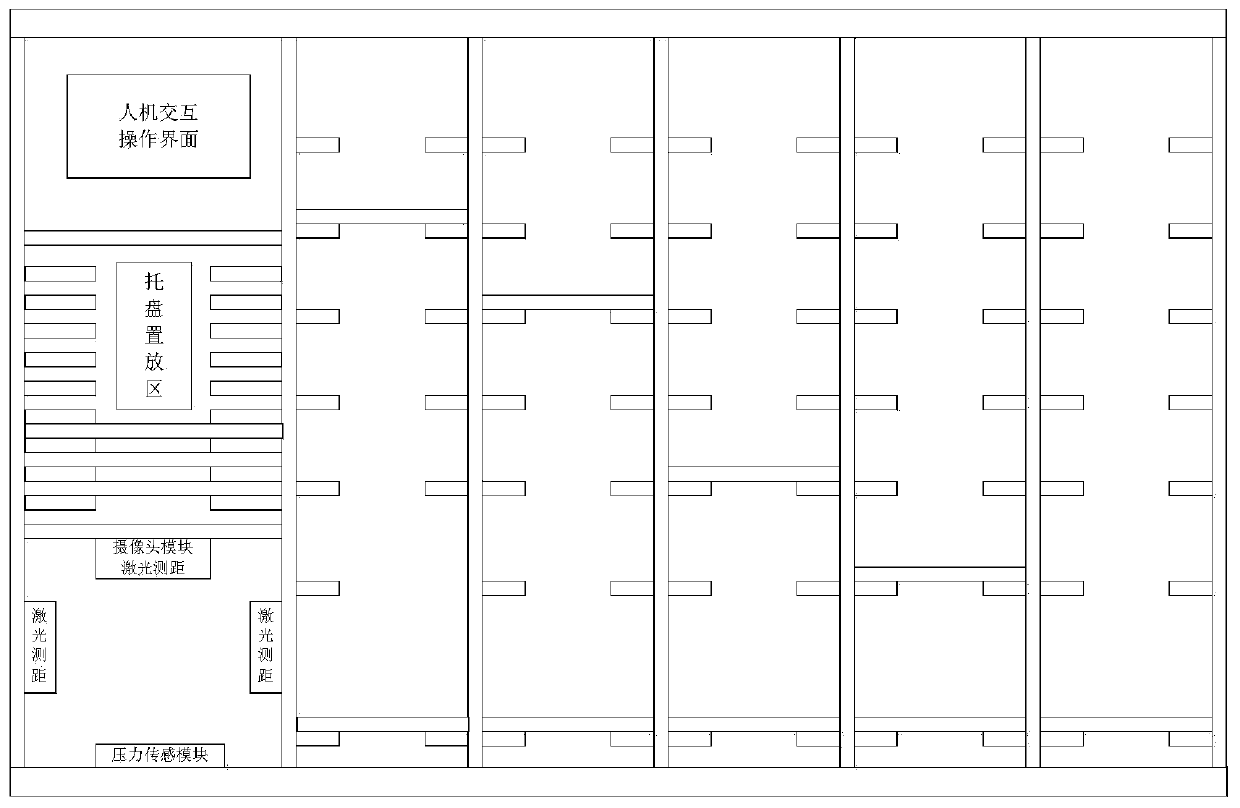

[0085] Such as figure 1 As shown, the intelligent container terminal system based on the flexible distribution storage area of the present invention includes five parts: a terminal control system, a display module, a communication module, a power supply module, and a flexible storage area. The terminal control system includes a control management module 1.1, Sensor module 1.2, stepper motor driver 1.3 and three-axis actuator 1.4, in which the control management unit takes the STM32 controller as the core, and the sensor module also includes a laser ranging module, a thin-film pressure sensor module, and a camera module; three-axis actuator 1.4 It includes a controllable XZY three-axis movement mechanism and an end effector in the Z-axis direction; the display module 1.5 includes a touch screen; the power module 1.6 includes a switching power supply to supply power to the entire terminal control system; The storage area described above includes unit cabinets with adjustable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com