Maintenance decision-making method based on equipment comprehensive health condition analysis and management

A health status and equipment integration technology, applied in the direction of data processing applications, instruments, resources, etc., can solve problems such as inaccurate judgment of equipment health status, achieve the effect of saving maintenance costs and prolonging equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

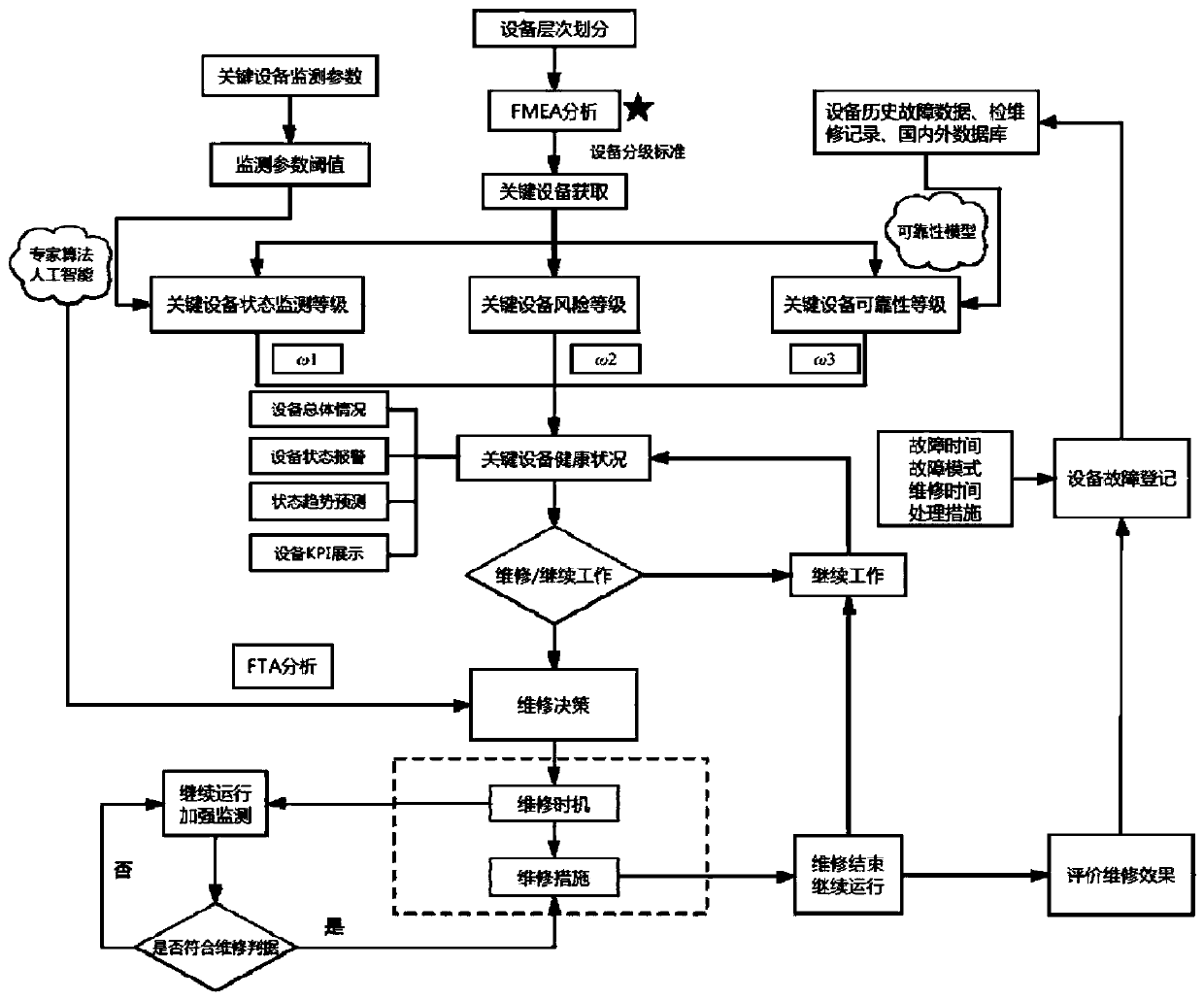

[0060] Such as figure 1 A maintenance decision-making method based on comprehensive equipment health status analysis and management shown includes the following steps:

[0061] a. Data collection

[0062] Collect all information and data of equipment; including but not limited to: equipment ledger, technical files, failure (defect) records, inspection and maintenance registration form, process card, PID diagram, DCS diagram, HAZOP analysis report, overhaul summary over the years, etc.

[0063] b. Equipment hierarchy division

[0064] According to the collected equipment ledger, determine the level of equipment (components), for example, divide the level into company-workshop-device-equipment (components). The purpose of device hierarchy division is to facilitate device management and use the relationship between devices to establish a reliability block diagram.

[0065] c. Acquisition of key equipment

[0066] Because of the large number of devices in a process business, c...

Embodiment 2

[0083] Taking a reciprocating compressor as an example, the application process of the present invention is described.

[0084] First, carry out FMEA analysis on the compressor, enumerate the possible failure modes, failure locations, failure causes, failure consequences and treatment measures of the compressor. Part of the FMEA analysis content can be found in Figure 8 .

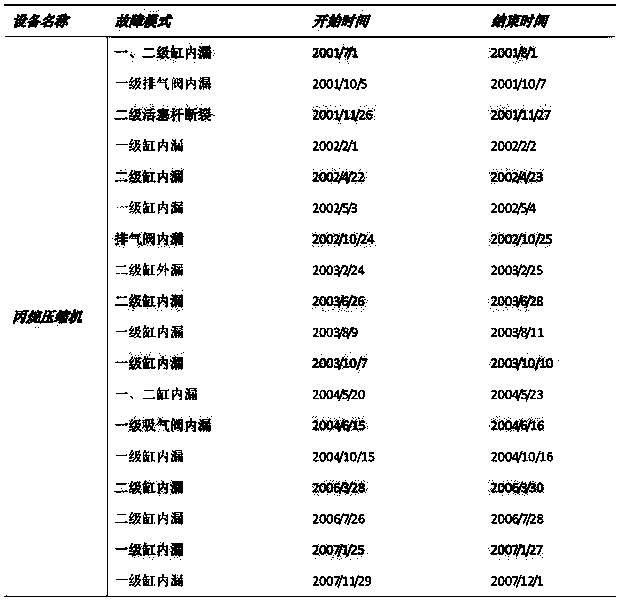

[0085] Secondly, collect the historical fault data of the compressor, some historical fault data such as Figure 9 shown.

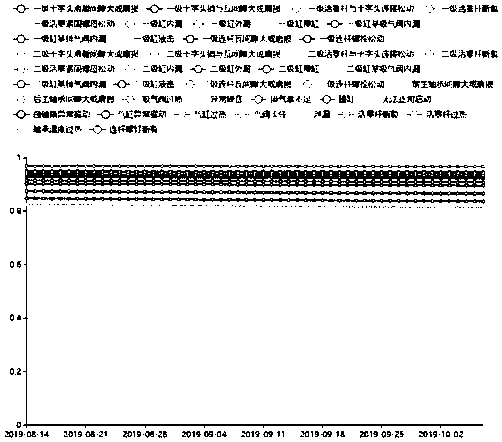

[0086] The Weibull distribution model is established by using historical fault data, and the overall reliability operation curve of the compressor and the operation curve of the compressor failure mode are calculated as follows: Figure 10 , Figure 11 shown.

[0087] According to the failure modes listed in the FMEA analysis, add the corresponding condition monitoring variable criteria, such as Figure 12 As shown, the condition monitoring variable criterion is used to infer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com