Closed cycle treatment method of soil leaching waste liquid

A closed-circuit circulation and treatment method technology, applied in the field of water pollution treatment, can solve the problems of no removal effect, etc., and achieve the effect of low treatment cost, efficient removal, and clear and reasonable process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

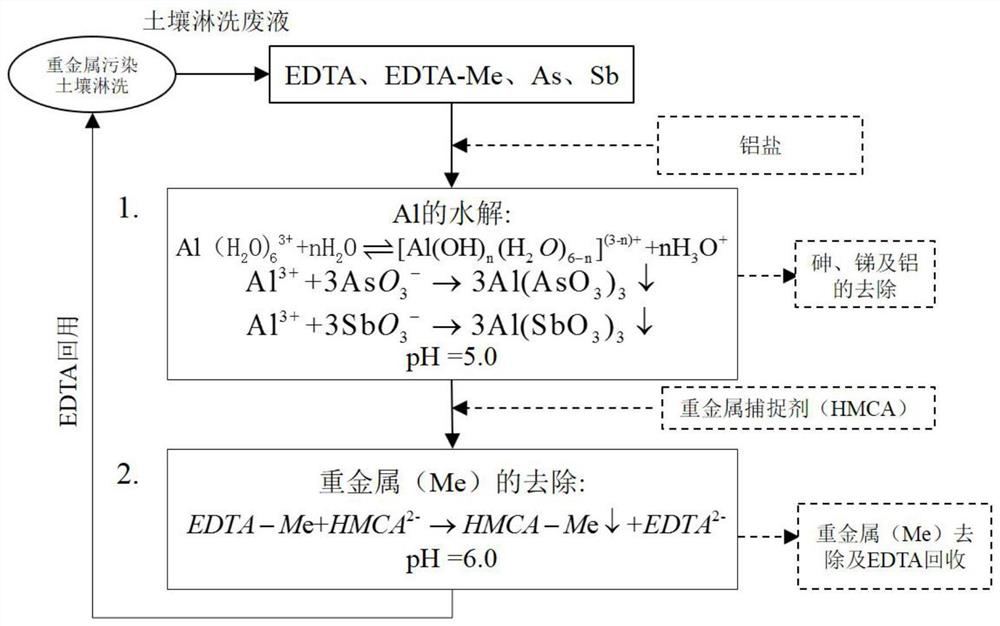

[0055] figure 1 It is the flow chart of the closed loop treatment method for soil washing waste liquid in Example 1.

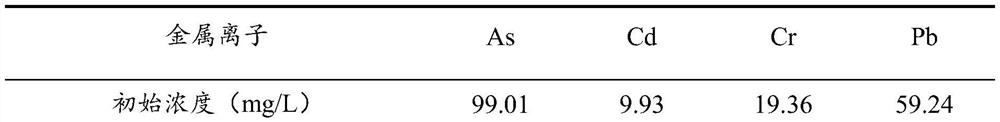

[0056] Use ultrapure water, arsenic acid (chemically pure), cadmium chloride pentahydrate (analytical pure), chromium nitrate nonahydrate (analytical pure) and lead nitrate (analytical pure) to prepare simulated soil leaching waste liquid, in which As, Cd , Cr, and Pb concentrations were 99.01mg / L, 9.93mg / L, 19.36mg / L, and 59.24mg / L, respectively, and the EDTA concentration was 0.01mol / L.

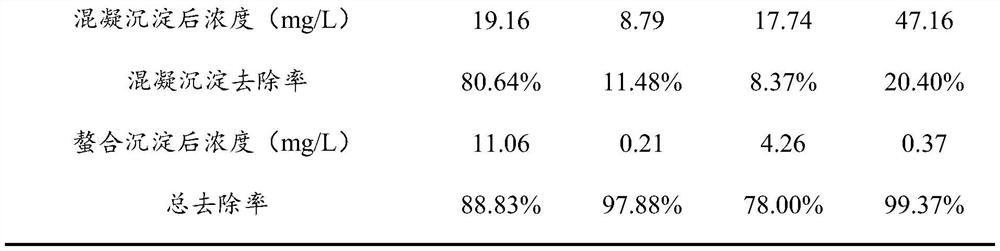

[0057] Take 400mL of simulated waste liquid and place it in a 500mL beaker, and adjust the pH of the solution to 5.0 with hydrochloric acid or sodium hydroxide. Then add 900 mg / L (calculated as Al) polyaluminum ferric silicate (the mass content of Al in the polyaluminum ferric silicate is 18.9%), and use hydrochloric acid or sodium hydroxide to adjust the pH value of the solution to 5.0. Under normal temperature conditions, mechanically stir rapidly (360r / min) for 5min, t...

Embodiment 2

[0063] Using ultrapure water, arsenic acid (chemically pure), potassium hexahydroxyantimonate (analytical pure), cadmium chloride pentahydrate (analytical pure), chromium nitrate nonahydrate (analytical pure), lead nitrate (analytical pure), heptahydrate Copper sulfate (chemically pure), zinc chloride (analytical pure), and simulated soil leaching waste liquid were prepared, in which the concentrations of As, Sb, Cd, Cr, Pb, Cu, and Zn were 1261.32mg / L, 745.42mg / L, 13.04mg / L, 27.37mg / L, 193.56mg / L, 183.37mg / L, 64.71mg / L, EDTA concentration is 0.1mol / L.

[0064] Take 400mL of simulated waste liquid and place it in a 500mL beaker, and adjust the pH of the solution to 5.0 with hydrochloric acid or sodium hydroxide. Then add 3600 mg / L (calculated as Al) polyaluminum ferric silicate (the mass content of Al in the polyaluminum ferric silicate is 18.9%), and use hydrochloric acid to adjust the pH value of the solution to 5.0. Under normal temperature conditions, mechanically stir ra...

Embodiment 3

[0069] In this embodiment, the actual soil leaching waste liquid is used as the processing object. The concentrations of As, Sb, Cd, Cr, Pb, Cu, and Zn in the soil washing waste liquid are 1264.36mg / L, 120.78mg / L, 8.94mg / L, 1.21mg / L, 64.21mg / L, 8.31mg / L, 98.14mg / L, EDTA concentration is 0.05mol / L, sodium citrate concentration is 0.01mol / L.

[0070] Take 400mL of simulated waste liquid and place it in a 500mL beaker, and adjust the pH of the solution to 5.0 with hydrochloric acid or sodium hydroxide. Then add 3600 mg / L (calculated as Al) polyaluminum ferric silicate (the mass content of Al in the polyaluminum ferric silicate is 18.9%), and use hydrochloric acid or sodium hydroxide to adjust the pH value of the solution to 5.0. Under normal temperature conditions, mechanically stir rapidly (360r / min) for 5min, then mechanically stir slowly (160r / min) for 30min. Then, add 2mg / L PAM, and stir mechanically at a slow speed (160r / min) for 30min at room temperature. Finally, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com