Fruit food packaging way and packaging equipment thereof

A technology of food packaging and equipment, which is applied in the field of food production and processing, can solve the problems of food filling efficiency, inconvenient opening of packaging bags, and single function, and achieve the effect of multiple functions, improving packaging efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

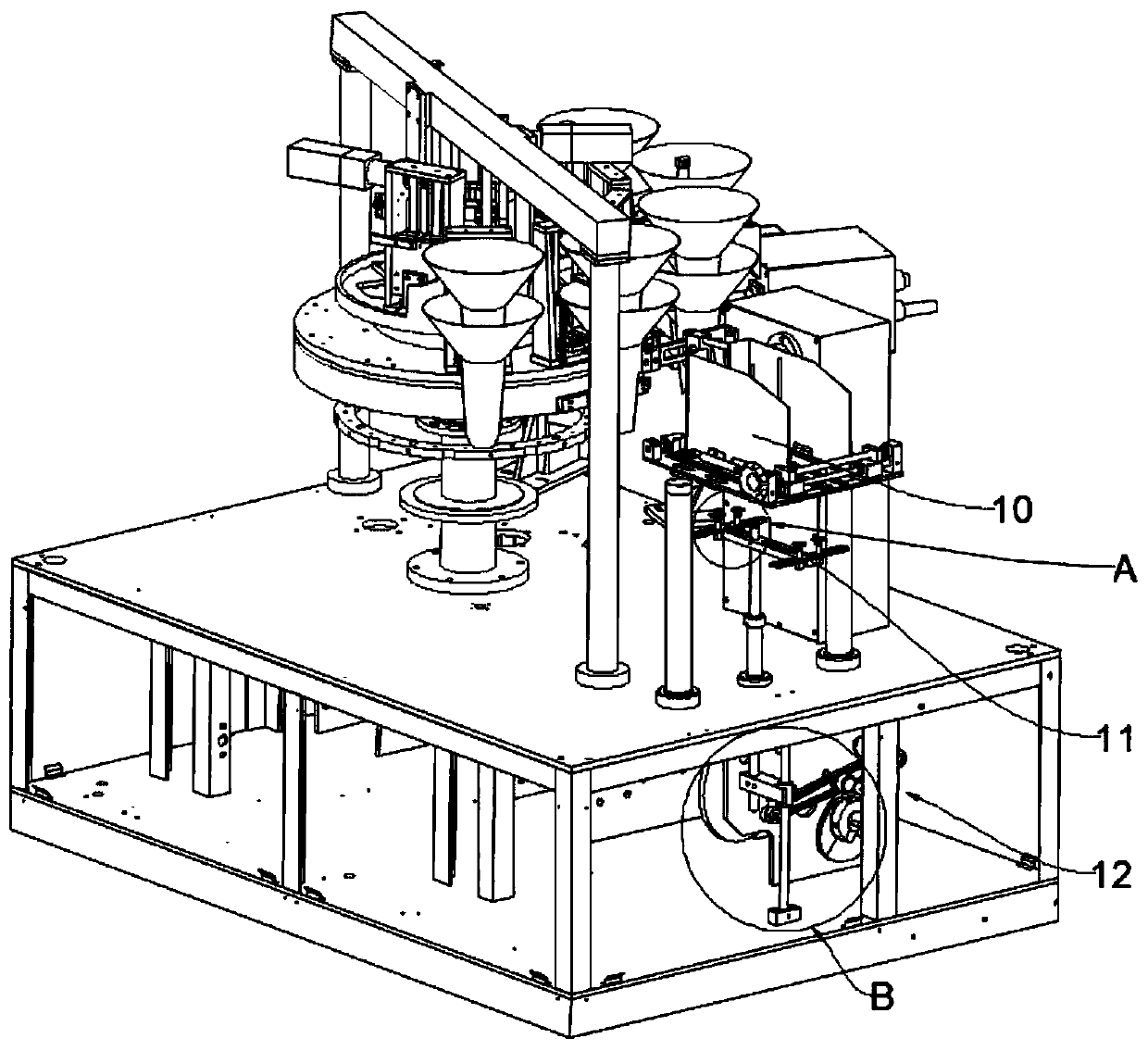

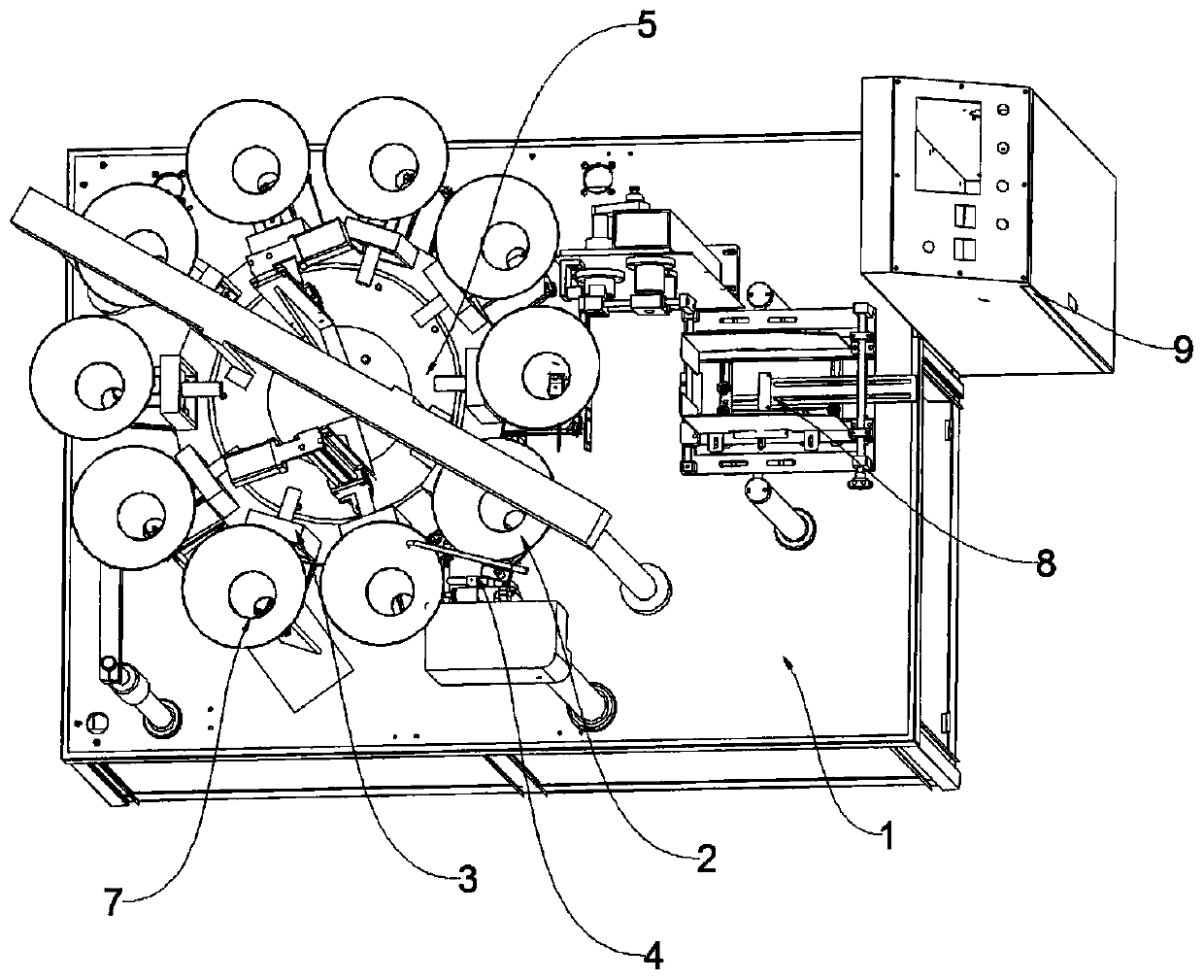

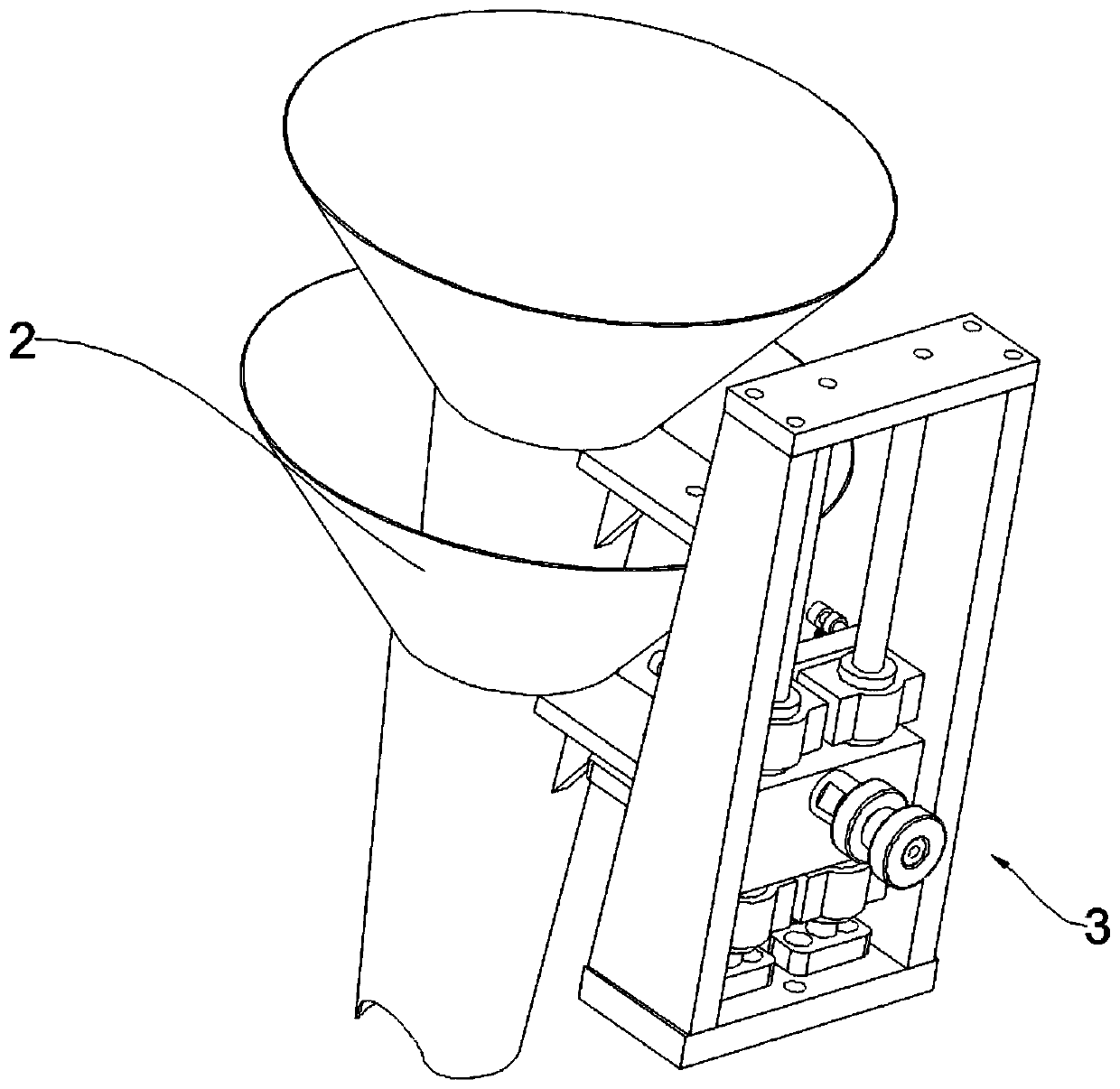

Embodiment 1

[0064] In Example 1, the number of hoppers 2 is set to ten, and the ten hoppers correspond to ten sets of lifting equipment 3. The packaging bags are placed in the bag storehouse 10, driven by a set of bag feeding devices through cams, and completed by PLC and pneumatic devices. The action of clamping the bag and feeding the bag, sending the bag to the fixture of the packaging machine, completes the feeding of the bag. A printer can be installed in the second station as required to complete the printing of the production date, production batch and other identifications. The bag opening station is equipped with a bag opening device 4. The bag opening device 4 includes a driving device 41 and an adsorption device 42. The control cooperates with the suction bag device to suck open the bag. At this time, the lower hopper is lowered and inserted into the bag under the control of the servo motor. In addition, this station has a bag blowing device to blow the bottom of the bag to ensu...

Embodiment 2

[0067] In Example 2, the number of hoppers 2 is set to ten, and the ten hoppers correspond to ten sets of lifting equipment 3. The packaging bags are placed in the bag storehouse 10, driven by a set of bag feeding devices through cams, and completed by PLC and pneumatic devices. The action of clamping the bag and feeding the bag, sending the bag to the fixture of the packaging machine, completes the feeding of the bag. A printer can be installed in the second station as required to complete the printing of the production date, production batch and other identifications. The bag opening station is equipped with a bag opening device 4. The bag opening device 4 includes a driving device 41 and an adsorption device 42. The control cooperates with the suction bag device to suck open the bag. At this time, the lower hopper is lowered and inserted into the bag under the control of the servo motor. In addition, this station has a bag blowing device to blow the bottom of the bag to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com