Method for recycling bromine in electronic waste smelting smoke dust through wet-process alkaline system

An electronic waste, alkaline technology, applied in the direction of bromine, bromine/hydrogen bromide, etc., can solve the problems of difficult, efficient and green processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

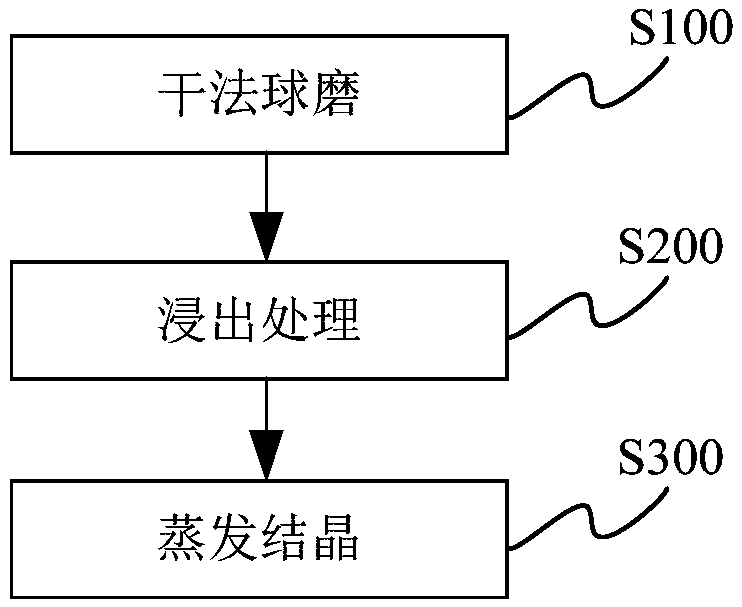

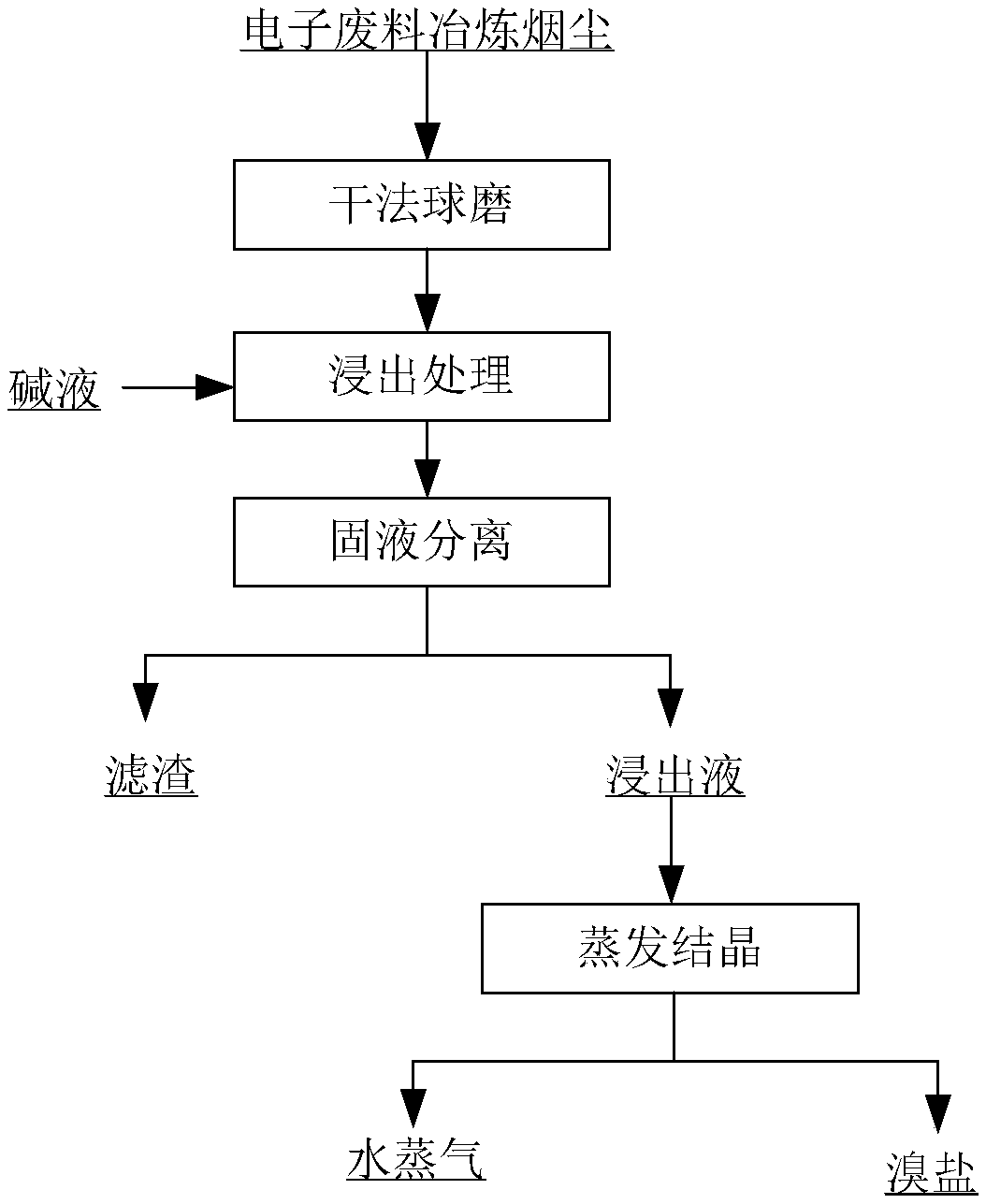

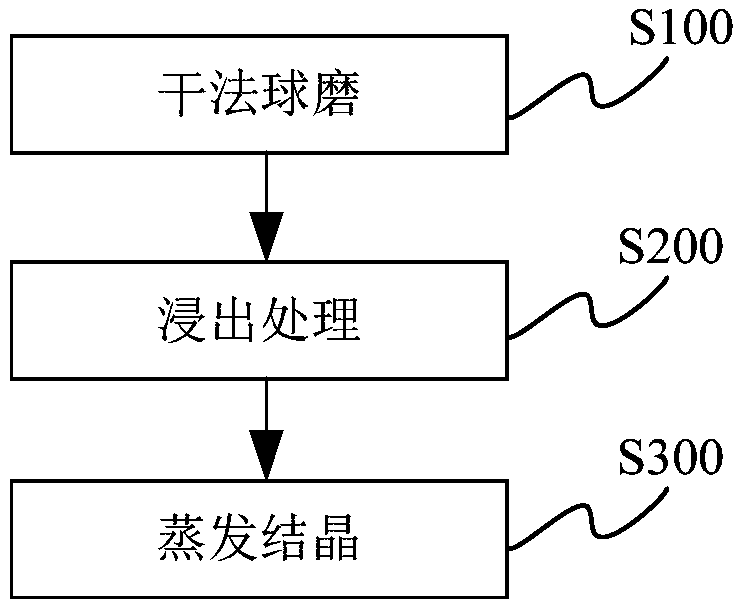

Method used

Image

Examples

Embodiment 1

[0042](1) Composition (%) on a dry basis of smelting dust from an electronic waste: F 0.16, Cl 7.85, Br 9.13, Cu 20.81, Zn9.91, Pb 8.83, Sn 2.90.

[0043] (2) The smelting fume is dry-milled for 30 minutes according to the ball-to-material mass ratio of 4:1 and the speed of 450r / min; add 2mol / LNH 4 OH solution, the ratio of liquid to solid is 3:1, the temperature of 40°C is passed through excess air and the reaction is stirred for 100 minutes, the leaching rate of bromine is 94.1%.

Embodiment 2

[0045] (1) Composition (%) on a dry basis of smelting fumes from a certain electronic waste: the same as in Example 1.

[0046] (2) The smelting fumes are subjected to dry ball milling for 30 minutes according to the mass ratio of balls to materials at 3:1 and the rotating speed at 500r / min; add 1mol / LNa 2 CO 3 The solution has a liquid-to-solid ratio of 3:1. Excessive air is passed through at a temperature of 40°C and stirred for 120 minutes. The leaching rate of bromine is 98.1%.

Embodiment 3

[0048] (1) Composition (%) on a dry basis of smelting fumes from a certain electronic waste: the same as in Example 1.

[0049] (2) The smelting dust is dry-milled for 10 minutes according to the mass ratio of the ball to material at 4:1, and the speed is 600r / min; add 1.0mol / L NaOH solution, the liquid-solid ratio is 4:1, and the temperature is 40°C. Excess air was stirred and reacted for 100 minutes, and the leaching rate of bromine was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com