Heat pipe system for boiler

A boiler and heat pipe technology, which is applied in the field of boiler heat pipe system, can solve the problems of not being able to completely prevent the medium steam from continuing to supply heat and waste heat, and achieve the effect of improving the automation level of boiler heating, high heat transfer efficiency, and fast heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

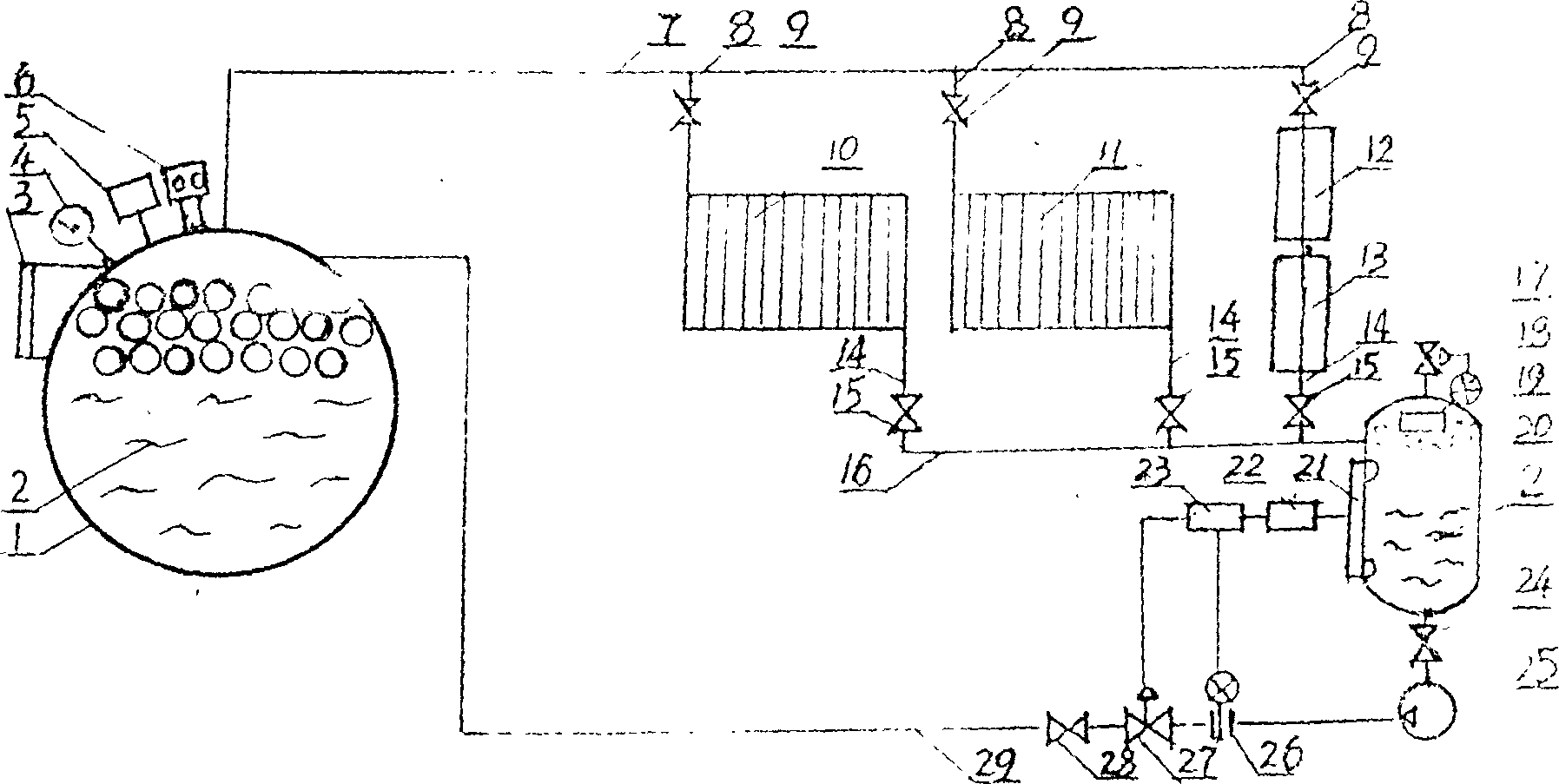

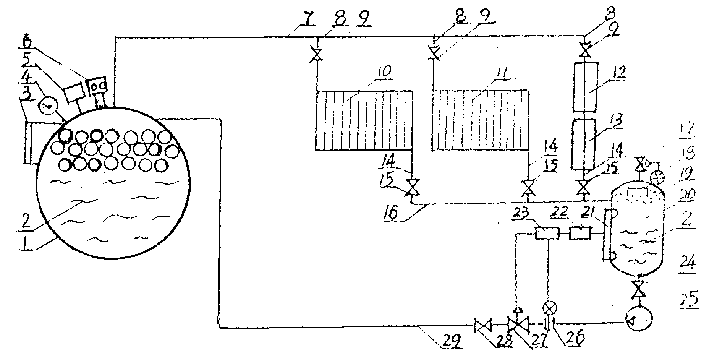

[0015] Such as figure 1 As shown, the present invention includes a boiler body 1 serving as an evaporator, a built-in working medium 2, a liquid level gauge 3, a pressure display control alarm 4, a temperature display control alarm 5 and a safety valve 6. After the boiler 1 is heated, the working medium 2 evaporates rapidly, and the steam enters the heating equipment 10, 11, 12, 13 through the steam flow pipe 7, each branch pipe 8, and the intake valve 9 to condense into a cold liquid with heat release. Heat-using devices 10, 11, 12, 13 acting as condensers, wherein 10 and 11 are connected in parallel, and 12 and 13 are connected in series to form independent branches. A liquid discharge valve 15 is arranged on the condensing return channel 14 of each heating equipment, and the total collecting pipe is 16 . The cold liquid flows in from the upper part of the intermediate storage tank 20 through the return branch pipe I4 and the liquid discharge valve 15 through the collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com