Plane target material burn-through alarm system

An alarm system and planar target technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of target waste, planar target damage, abnormal state of coating line, etc., to reduce production costs, The effect of protecting the target and reducing the waste of the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

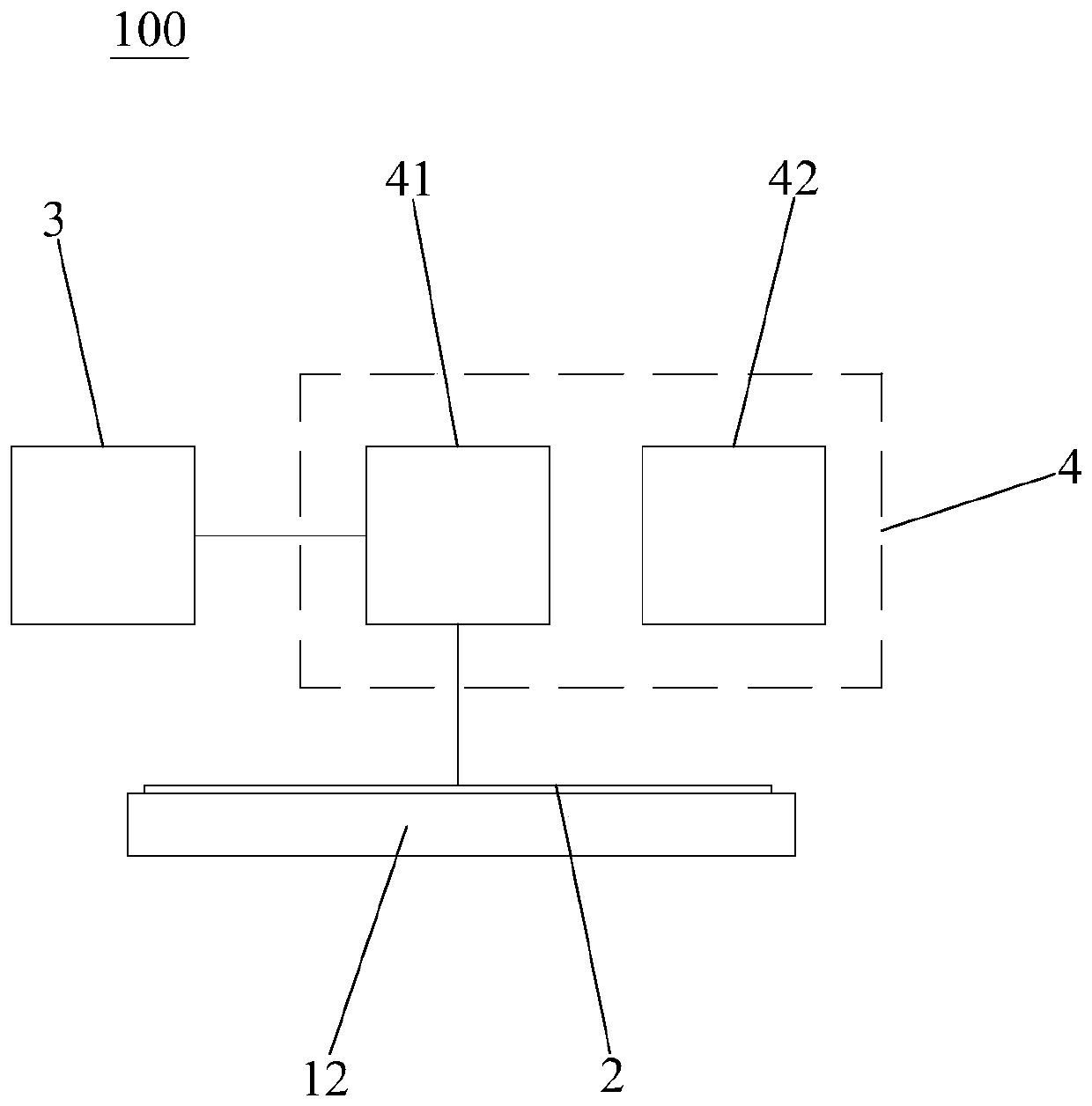

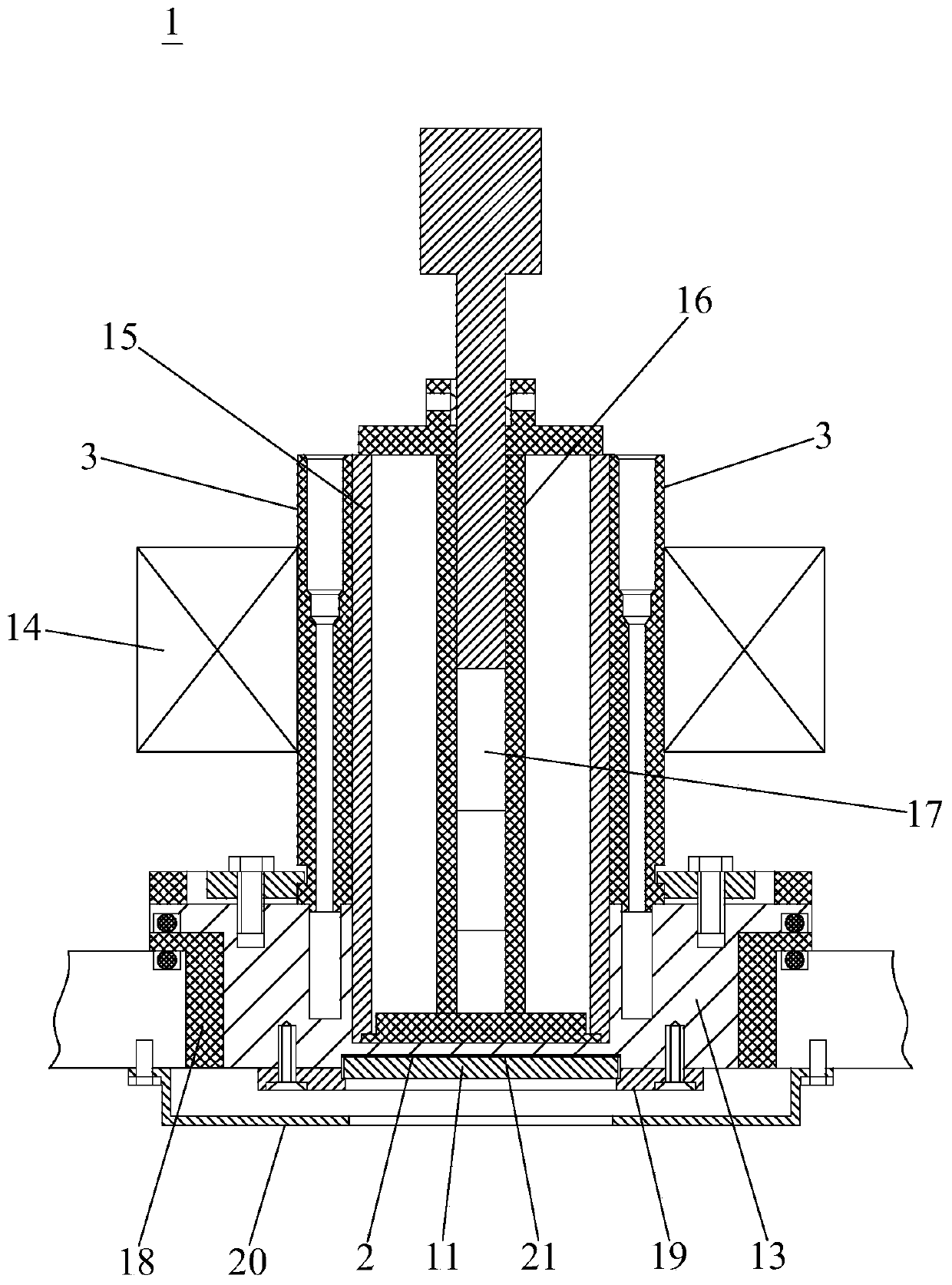

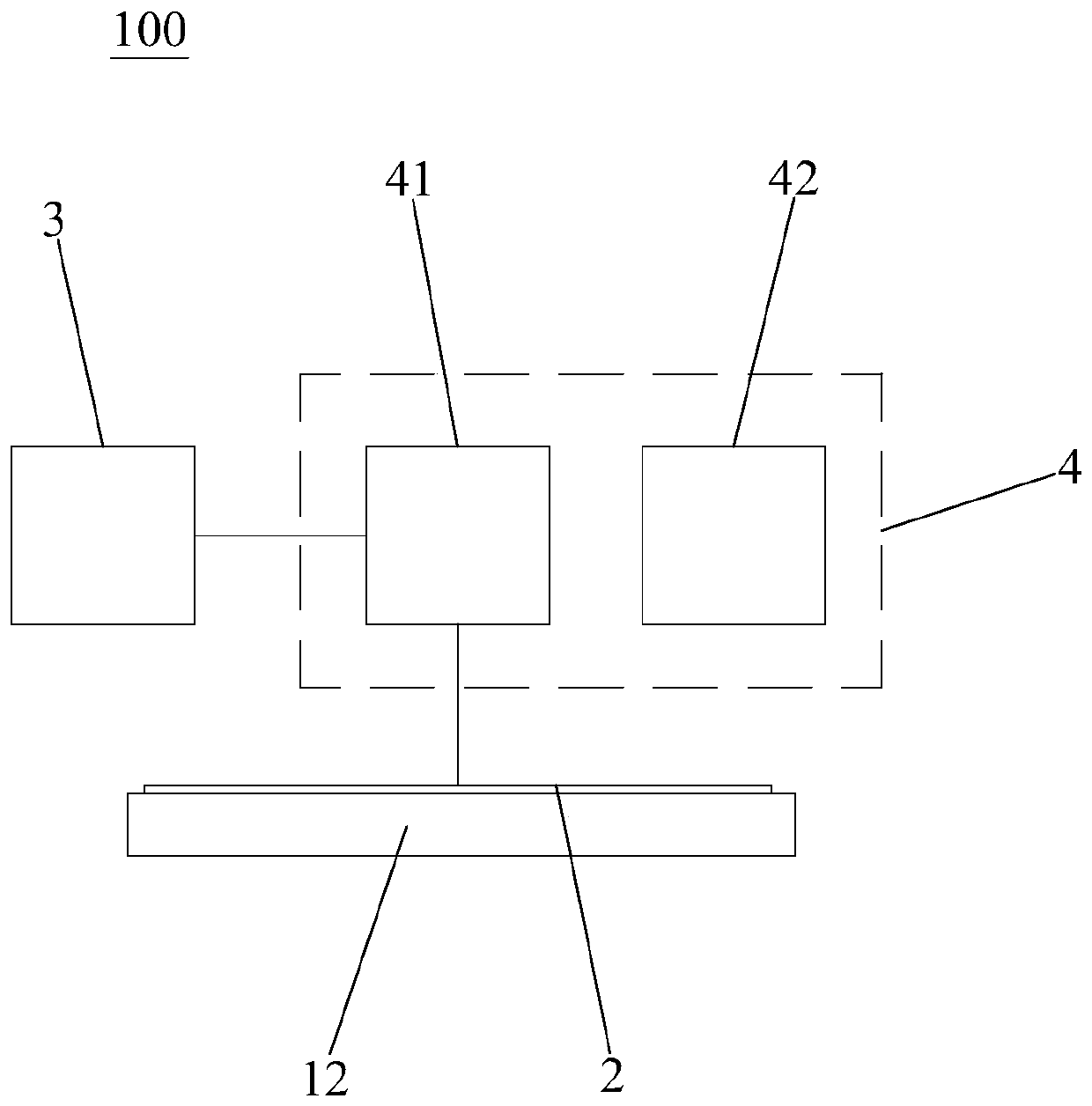

[0017] Such as figure 1 As shown, the planar target burn-through alarm system 100 of the present invention includes a magnetron sputtering planar target 1, a wire 2, an alarm 3 and a control system 4. The magnetron sputtering planar target 1 is provided with a planar target 11, The wire 2 is arranged on the bottom of the planar target 11 and the wire 2 is wrapped with an insulating layer, the wire 2 is electrically connected to the control system 4, and the control system 4 is electrically connected to the alarm 3 connect.

[0018] The number of the wires 2 is two, and they are arranged at the bottom of the etching track of the planar target 11 .

[0019] The control system 4 includes a processor 41 and an operating system 42 , the wire 2 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com