Preparation method and application of heat transfer printing medium-temperature disperse dye ink

A technology of disperse dyes and thermal transfer printing, applied in the field of dyeing, can solve the problems of poor dye sublimation fastness, low molecular weight of dyes, and easy staining, etc., and achieve excellent color effects, high sublimation fastness, and excellent dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned medium-temperature disperse dye ink for thermal transfer printing, the preparation method comprising: mixing various raw materials to obtain the medium-temperature disperse dye ink for thermal transfer printing. Therefore, the operation is simple, convenient and easy to realize.

[0051] In some embodiments of the present invention, the above preparation method includes: mixing the ground-treated medium-temperature disperse dye with other raw materials to obtain the thermal transfer medium-temperature disperse dye ink. Thus, it is possible to fully mix the medium temperature disperse dye with other raw materials.

[0052] In some embodiments of the present invention, the medium-temperature disperse dye, the dispersant and part of the water are mixed and then subjected to the grinding treatment to obtain a color paste; the color paste is mixed with the rem...

Embodiment 1

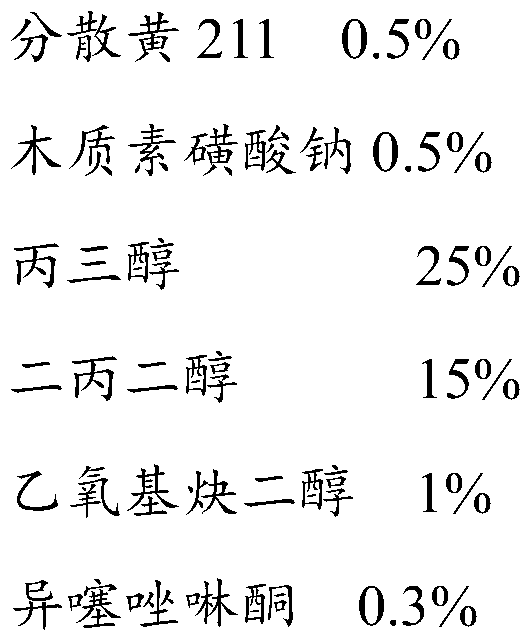

[0062] Thermal transfer medium temperature disperse dye ink includes the following mass fractions of raw materials:

[0063]

[0064] Deionized water balance

[0065] The preparation method of the ink: Firstly, the C.I. Disperse Yellow 211 is ground into micro-particles with a diameter of 1-300 nanometers, and then it is mixed with the above-mentioned other ingredients in proportion and then filtered at a level of about 0.5 microns to obtain a digital printing yellow. ink.

Embodiment 2

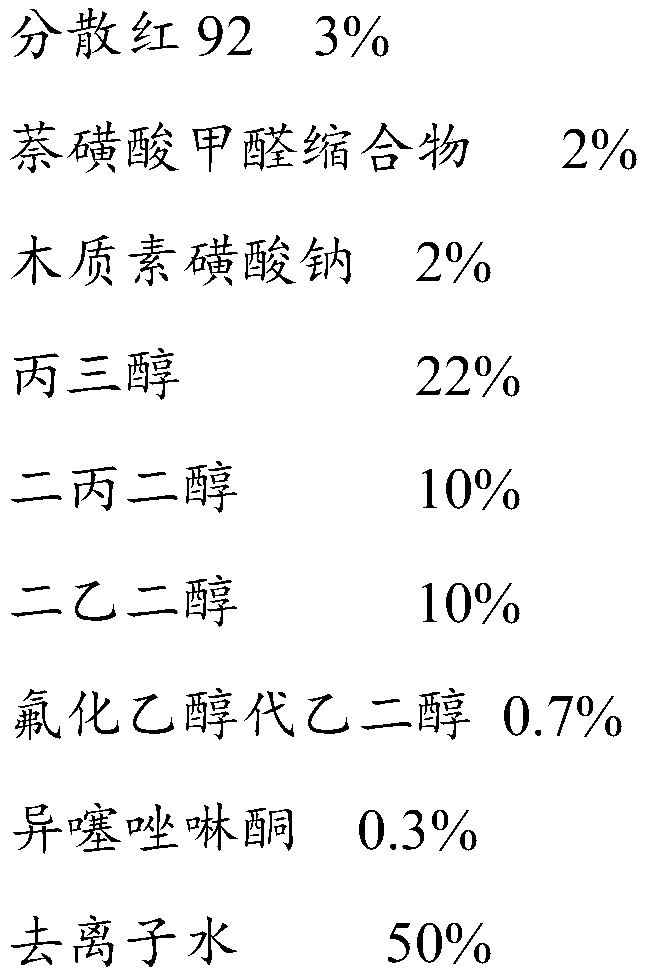

[0067] Thermal transfer medium temperature disperse dye ink includes the following mass fractions of raw materials:

[0068]

[0069] Ink preparation method: mix C.I. Disperse Red 92 dye and dispersant with part of water (the weight of this part of water is equal to the sum of the weight of C.I. Disperse Red 92 dye and dispersant), and grind to a mixture with a particle size of 1-300 , and then the above-mentioned other components and the remaining water were mixed in proportion, and filtered through a 0.5 μm filter element to obtain digital printing magenta ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com