Combined connection module of fabricated building and combined plate body structure thereof

A combined connection and assembly technology, which is applied in building construction and construction, can solve the problems of difficult transportation, high production cost, and high space occupancy of individual components, and achieve the effect of speeding up the construction progress and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] In prefabricated buildings, prefabricated plate structures and connecting mechanisms are often used for on-site assembly. Compared with the existing pouring and molding methods of fixed structures, it can improve assembly efficiency and speed up construction progress. The main problem of the existing prefabricated buildings assembled from plates is that the existing connectors 2 cannot adapt to long-term use. At present, in order to cope with short-term use, some prefabricated buildings adopt a connection structure that is easy to disassemble. Improper maintenance, resulting in cracks in the joints of the buildings formed before reaching the service life. If pouring or other fixed connection methods are used, the high-efficiency advantages of prefabricated buildings will be lost.

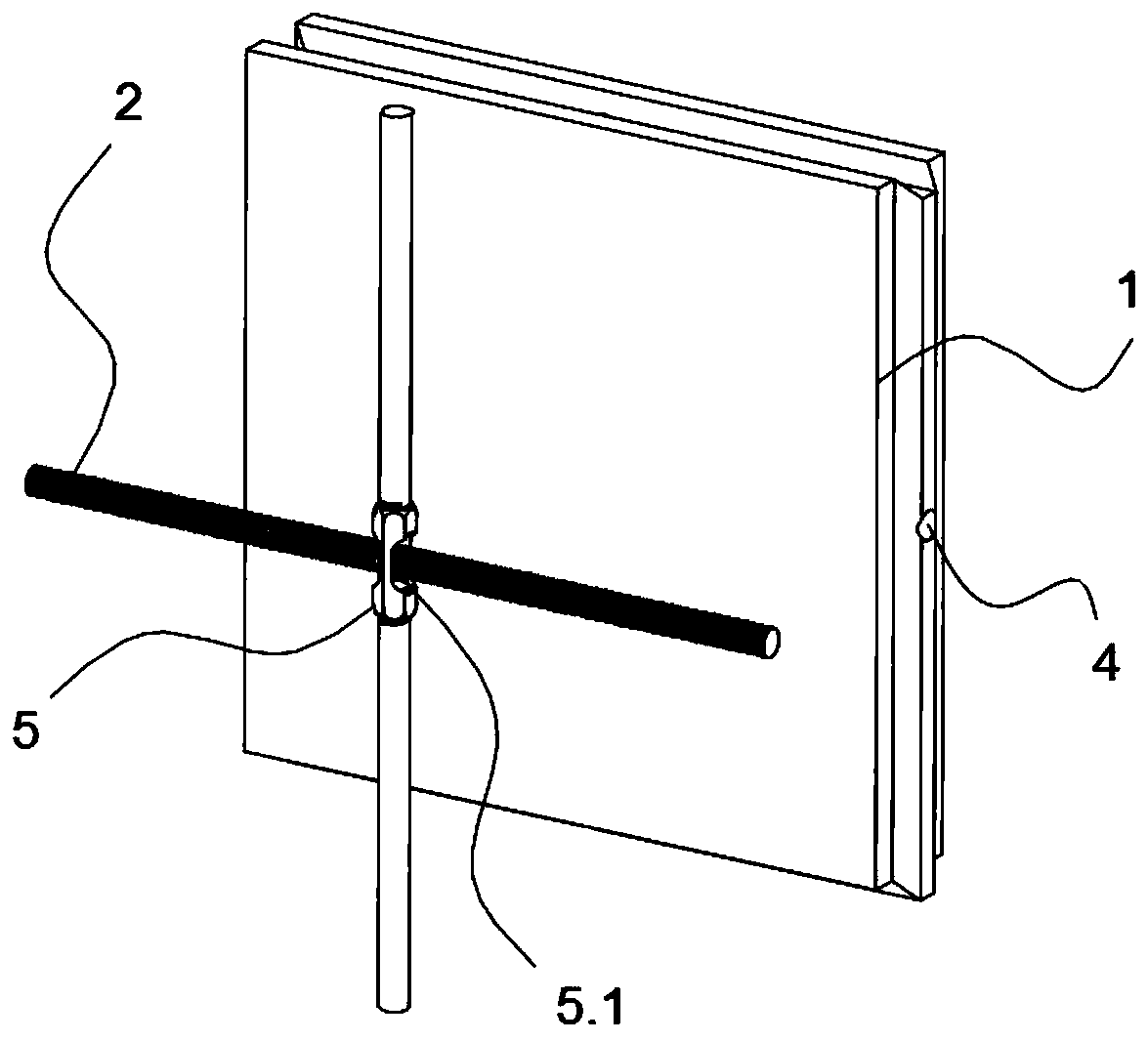

[0069] This embodiment is specifically a combined connection module for a prefabricated building, including a module board 1, a plurality of the module boards 1 are spliced with each other ...

Embodiment 2

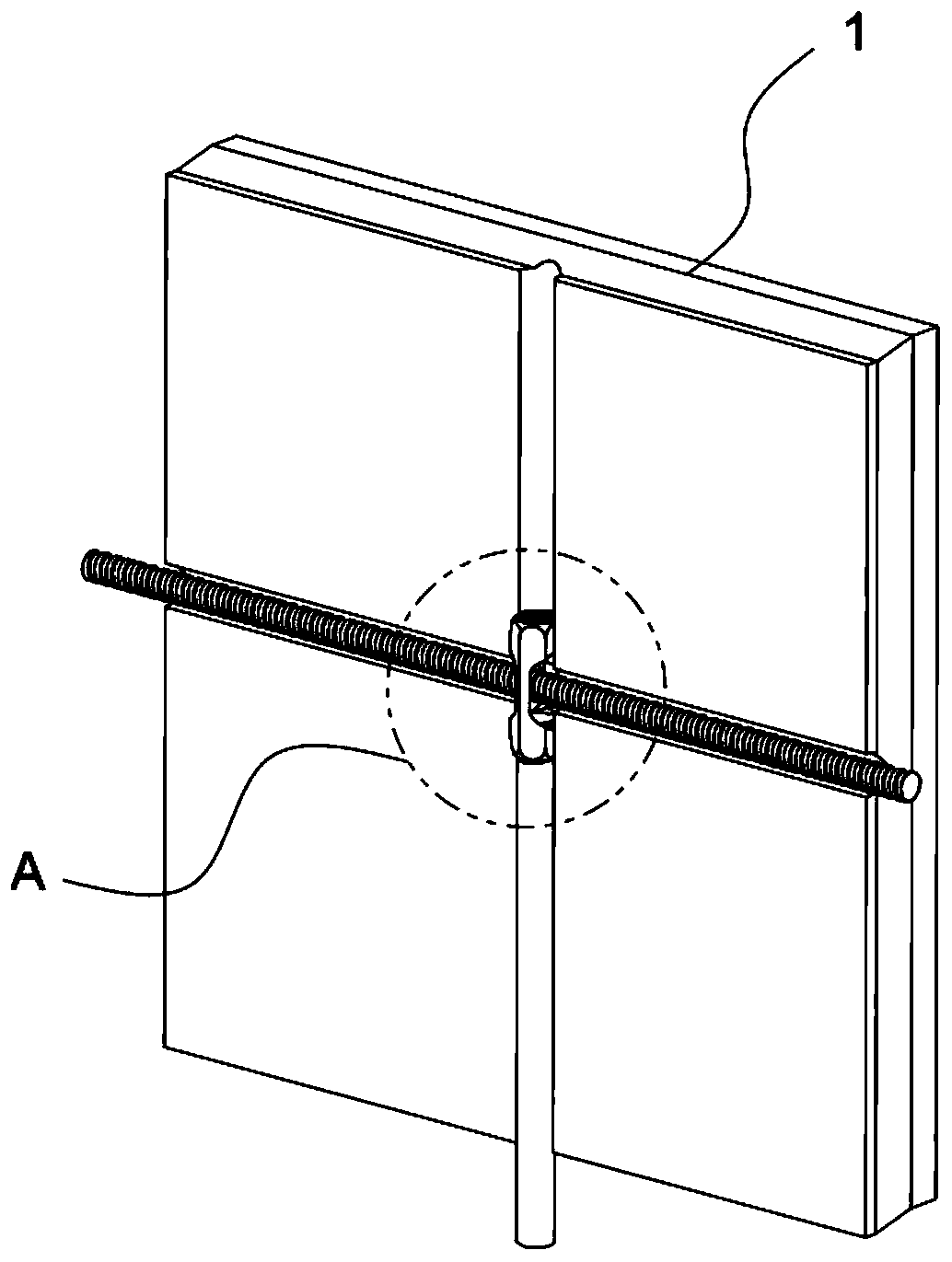

[0076] This embodiment discloses a combined connection module for a prefabricated building, including a module board 1, a plurality of the module boards 1 are spliced together to form a board surface, and a connector 2 for connecting the module boards 1 to form a board surface The module board 1 is provided with a connector 2 that connects and tightens adjacent module boards 1 , and the connector 2 is set in the connection hole 4 opened in the module board 1 .

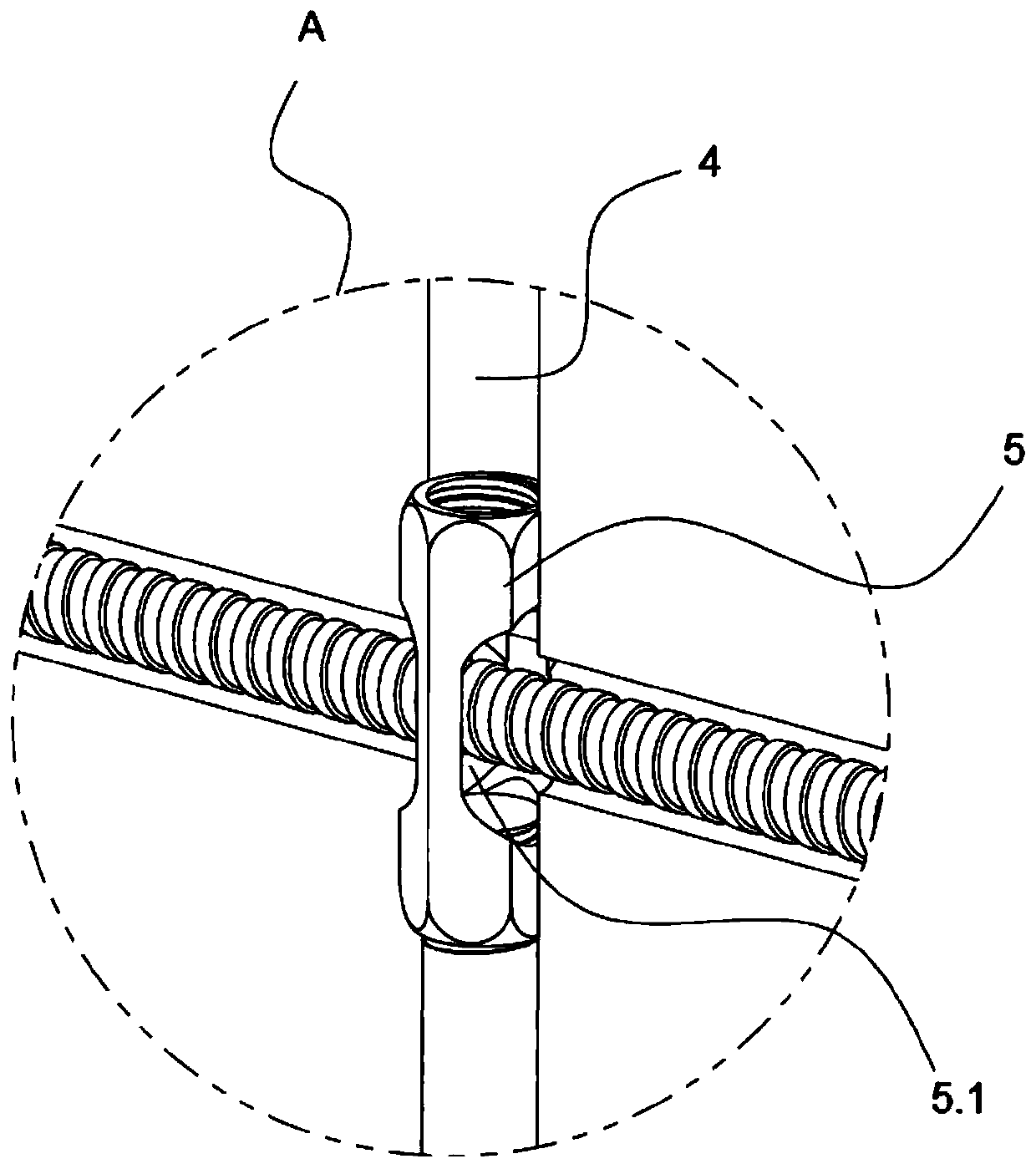

[0077] like Figure 5 As shown, the structure of the module board 1 of this embodiment is shown. The difference from Embodiment 1 is that two connecting holes 4 parallel to each other are provided in the horizontal direction, and a connecting hole 4 extending along the midline is also provided in the vertical direction. Hole 4.

[0078] However, the connector 2 used in this embodiment includes two types of screw rod and steel cable, wherein the screw rod structure is generally used. During installation, it is the s...

Embodiment 4

[0087] This embodiment is a combined connection module of a prefabricated building, the basic module of which is a module board 1, such as Figure 11 As shown, a plurality of modular panels 1 are spliced together to form a wall. The module boards 1 have a square structure, and connecting pieces 2 are provided between adjacent module boards 1 for connecting and making them form walls.

[0088] The central position of one end surface of the module board 1 is recessed inwardly to form a sinker 3 , and the sinker 3 is a circular blind hole structure. The inner wall of the sinking tank 3 is provided with a connection hole 4 whose axis is parallel to the end face and passes through the module board 1, and the adjacent module boards 1 correspondingly connected on a single module board 1 are respectively provided with a connection hole 4, and through The connecting piece 2 disposed in the connecting hole 4 connects adjacent module boards 1 .

[0089] Wherein, the connector 2 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com