Fully variable electro-hydraulic valve system

A valve, variable technology, applied to non-mechanically actuated valves, engine components, machines/engines, etc., can solve the problems of constant crankshaft rotation angle, oil loss, affecting the normal operation of the system, etc., to achieve convenient control and response speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

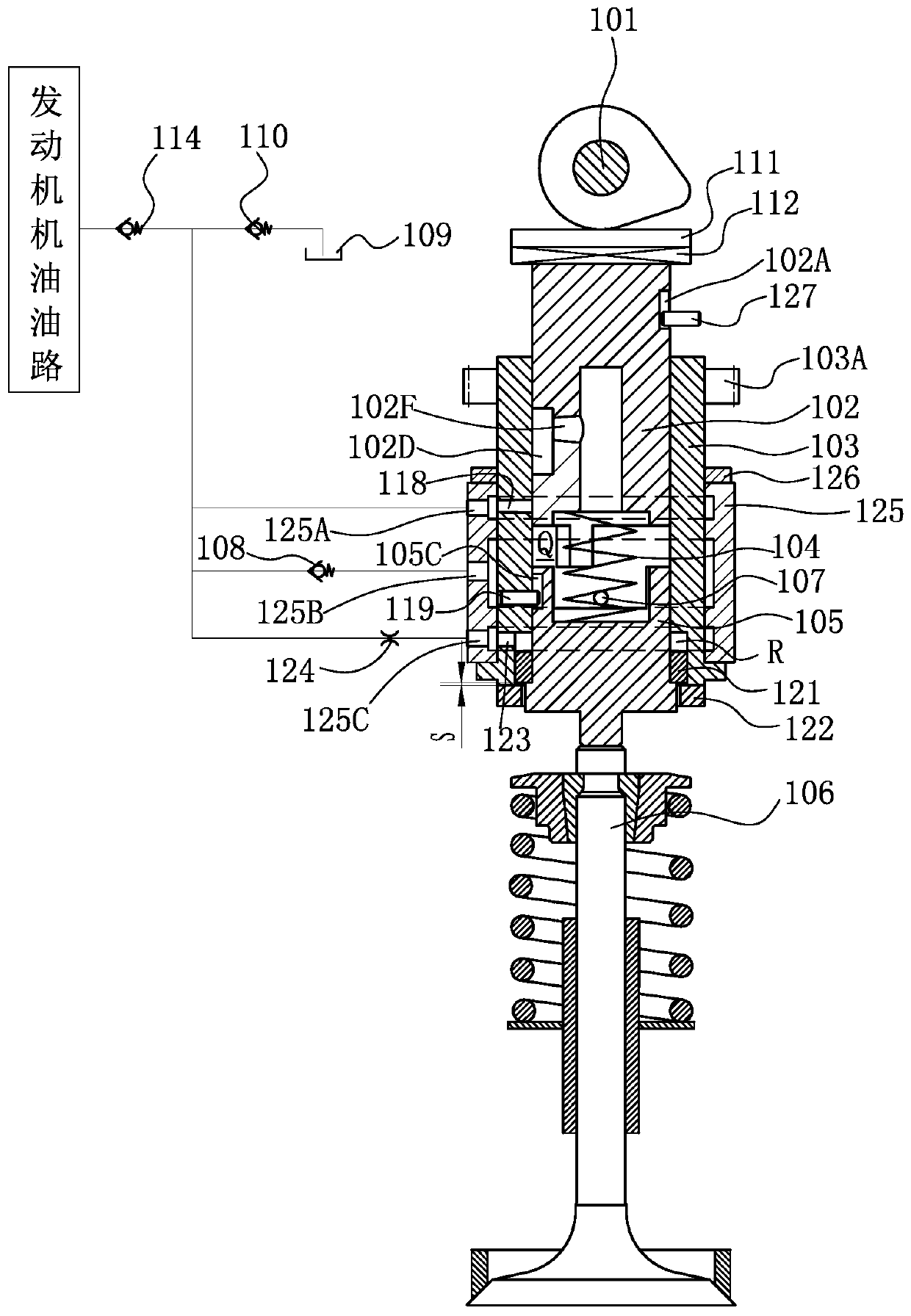

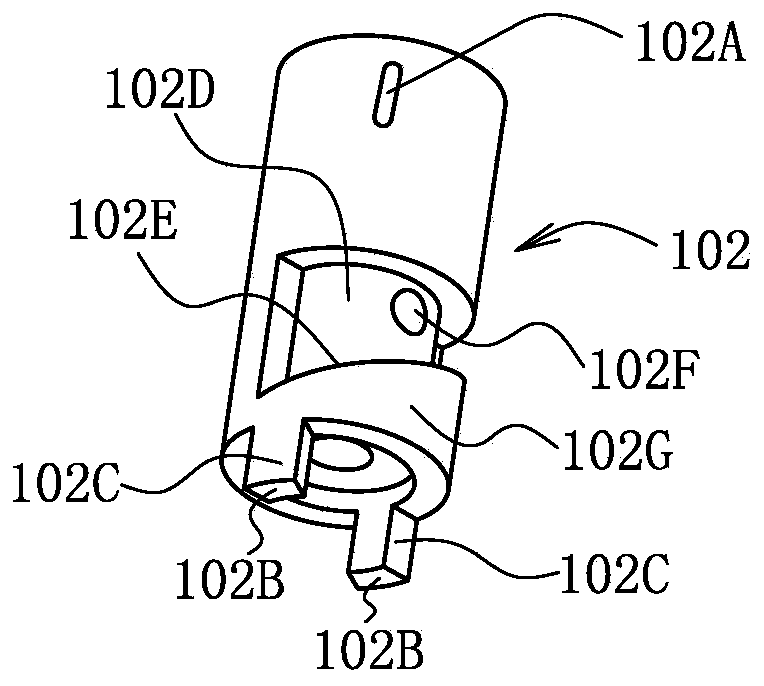

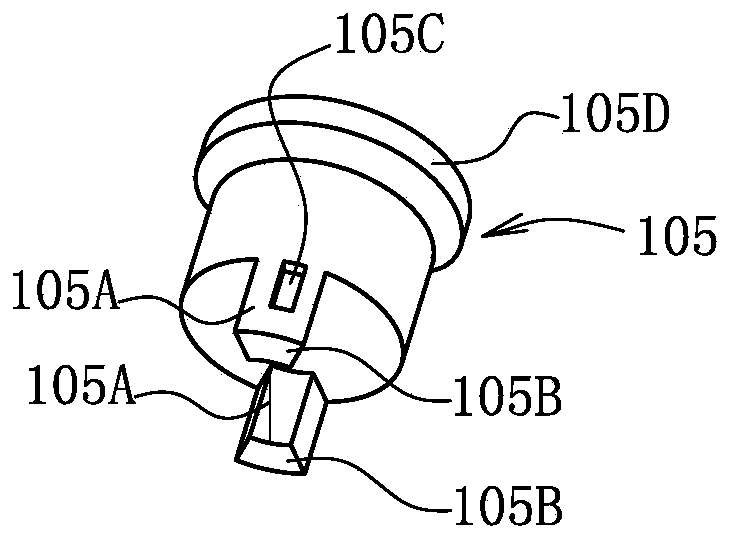

[0034] Such as figure 1 As shown, a fully variable electro-hydraulic valve system, a limit sleeve 125 is arranged outside the sliding sleeve 103, the limit sleeve 125 is fixed relative to the engine, the sliding sleeve 103 and the limit sleeve 125 are rotatably installed and the sliding sleeve 103 is limited by the axial direction. The constraints of the position structure, in the present embodiment, the axial limit structure is the retaining ring 126 and the flange located at the two ends of the limit sleeve 125, the flange and the sliding sleeve 103 are set as one, and the retaining ring 126 is fixedly connected with the sliding sleeve 103, Of course, for the purpose of making the sliding sleeve 103 only rotate but not move relative to the limiting sleeve 125 , other axial limiting structures can also be used, which will not be repeated here.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com