Garbage incineration device

A waste incineration and combustion disk technology, which is applied in the field of boiler equipment manufacturing and waste incineration devices, can solve the problems of high energy consumption and incomplete combustion of ash in the incineration process, and achieve the effects of reducing difficulty, increasing porosity, and accelerating feed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The waste incineration device of the present invention can be made of the following materials, and is not limited to the following materials, for example: stainless steel, refractory ceramics, motors, shaped steel, slag extractors, feeders, etc.

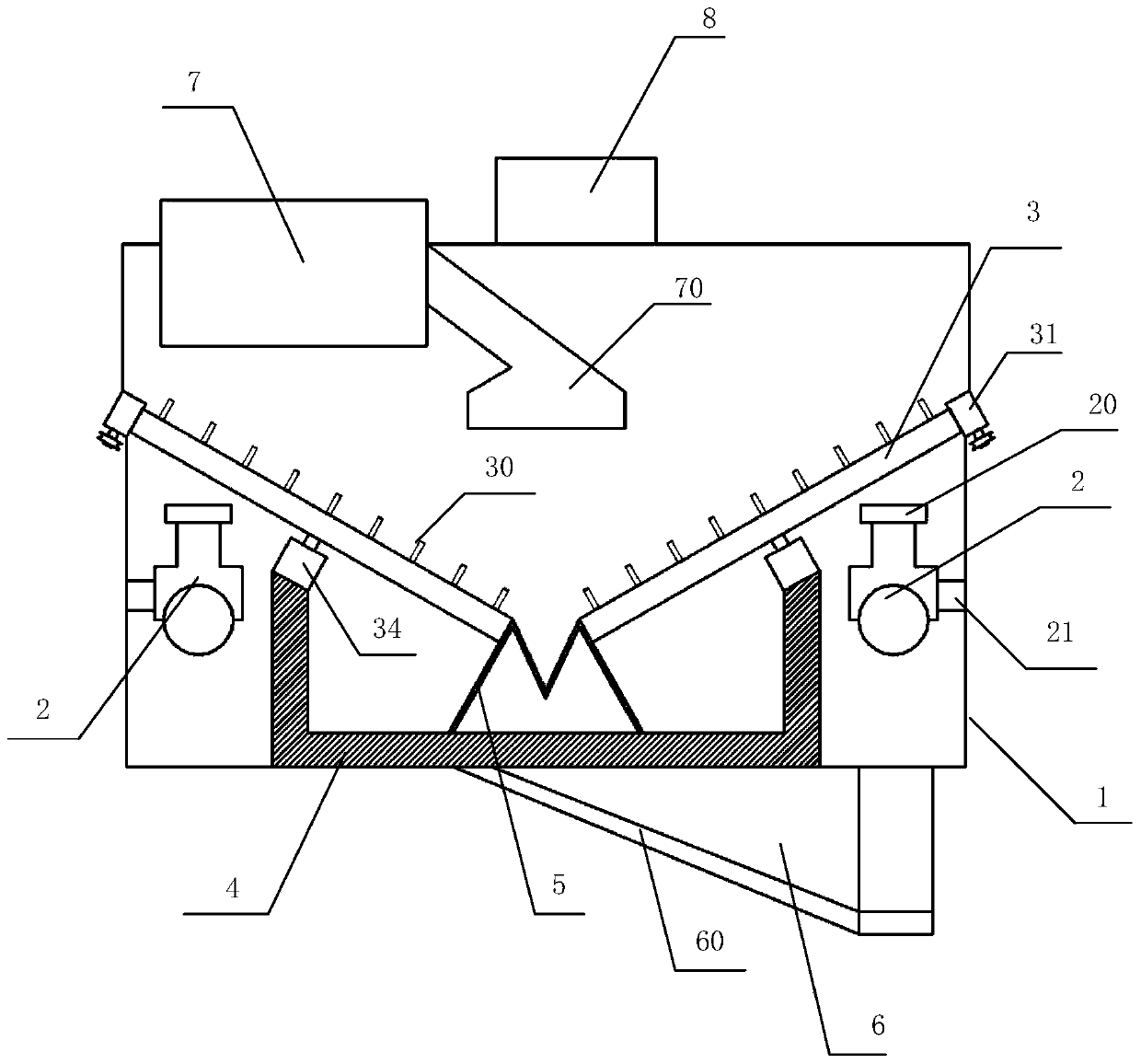

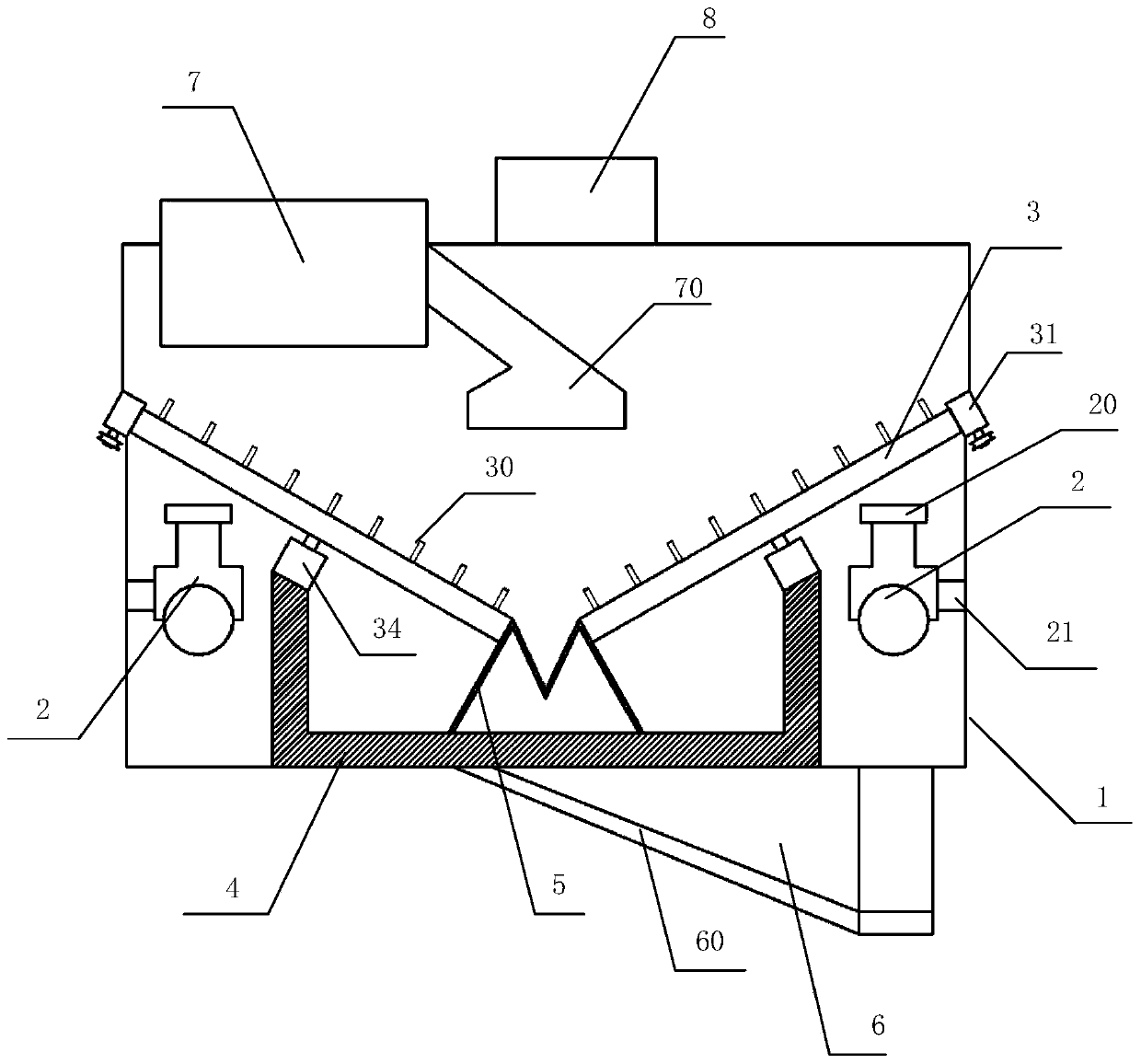

[0020] Such as figure 1 Shown is the side structural view of the waste incineration device of the embodiment of the present invention; the waste incineration device of the embodiment of the present invention includes: a furnace body 1; the furnace body 1 is a closed cavity, and the top of the furnace body 1 is arranged There is a feed inlet 70 and a smoke exhaust outlet 8, and a slag outlet 6 is provided at the bottom of the furnace body 1 .

[0021] Generally, a feeding device 7 is provided at the front end of the feeding port 70, so as to ensure that garbage can continuously enter the furnace body from above the furnace body for combustion.

[0022] There is a flue gas guide pipe on the outside of the smoke exhaust port 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com