Resonant cavity structure based on magneto-optical effect and laser

A magneto-optical effect and resonant cavity technology, applied in the field of lasers, can solve problems such as troublesome operation, and achieve the effect of improving stability and changing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

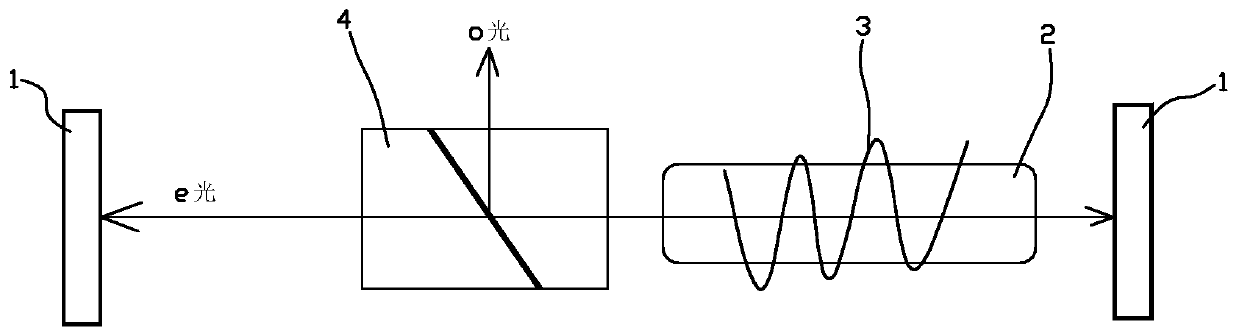

[0021] refer to figure 1 As shown, a kind of resonant cavity structure based on the magneto-optical effect provided by the present embodiment includes: two laser high reflection mirrors 1 arranged at intervals and a polarization device and a magnetic field generator ( not shown) and magneto-optical material body 2. Specifically, the resonant cavity is a linear resonant cavity, and the two laser high-reflection mirrors 1 are arranged opposite to each other. The incident beam is reflected by the two laser high-reflection mirrors 1 to oscillate and amplify in the resonant cavity to form an oscillating beam (ie, e-light). The polarizer is a Glan-Taylor prism 4 , and the oscillating light beam (ie, e-light) can propagate through the Glan-Taylor prism 4 and the magneto-optical material body 2 .

[0022] The magnetic field generator corresponds to the magneto-optical material body 2, and the magnetic field 3 generated by the magnetic field generator has a certain component in the di...

Embodiment 2

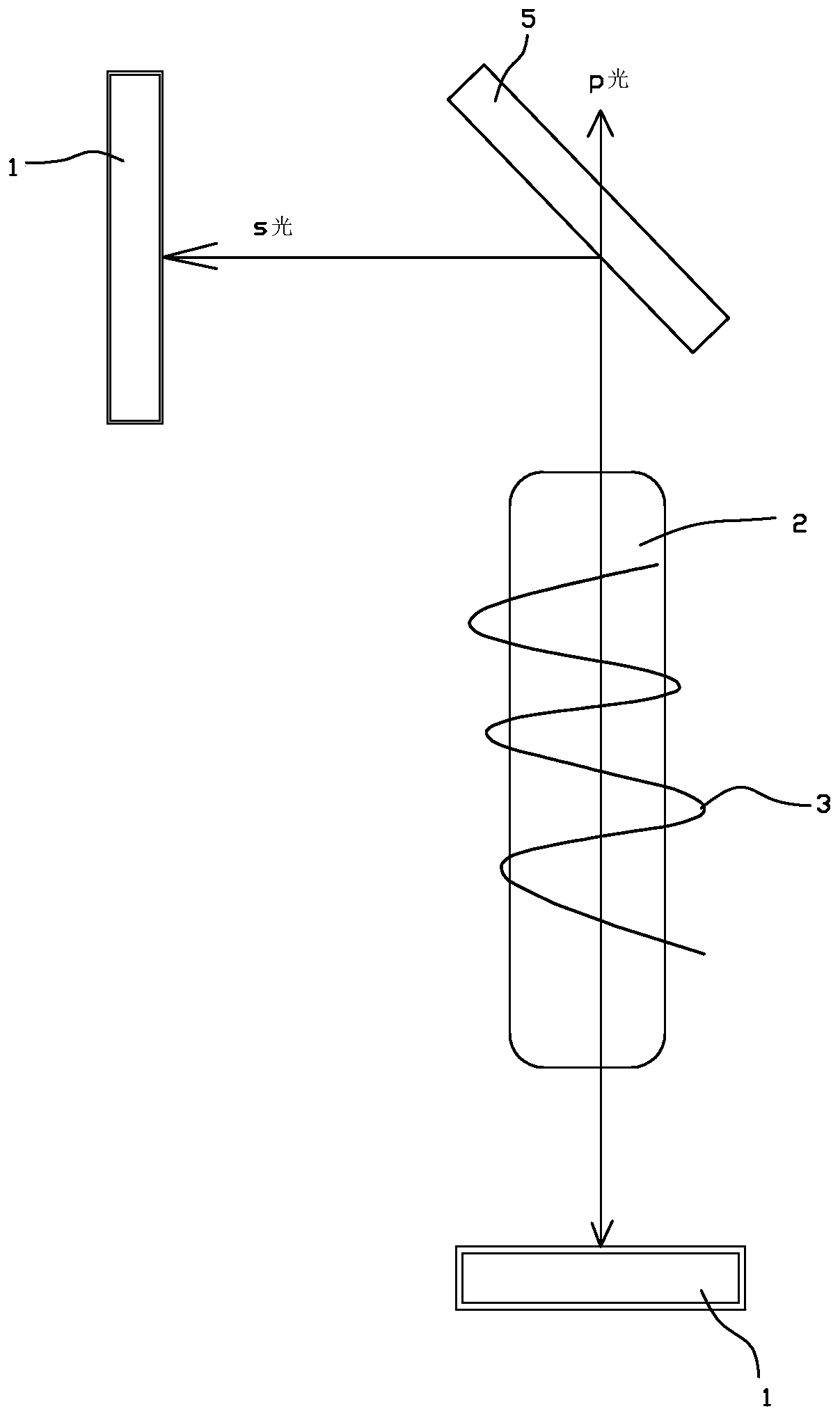

[0030] refer to figure 2 As shown, a kind of resonant cavity structure based on the magneto-optical effect provided by the present embodiment includes: two laser high reflection mirrors 1 arranged at intervals and a polarization device and a magnetic field generator ( not shown) and magneto-optical material body 2. Specifically, the resonant cavity is an "L" shaped resonant cavity, and two high-reflection laser mirrors 1 are respectively arranged at the two ends of the "L" shaped resonant cavity, and the polarizing device is a polarizing beam splitter 5, and the polarizing beam splitting mirror 5 is set At the corner position of the "L" shaped resonator. The incident light beam is refracted by the polarizing beam splitter 5, so as to reflect and oscillate back and forth between the two laser high reflection mirrors 1 to form an oscillating light beam (s-ray in this embodiment).

[0031] The magnetic field generator corresponds to the magneto-optical material body 2, and the...

Embodiment 3

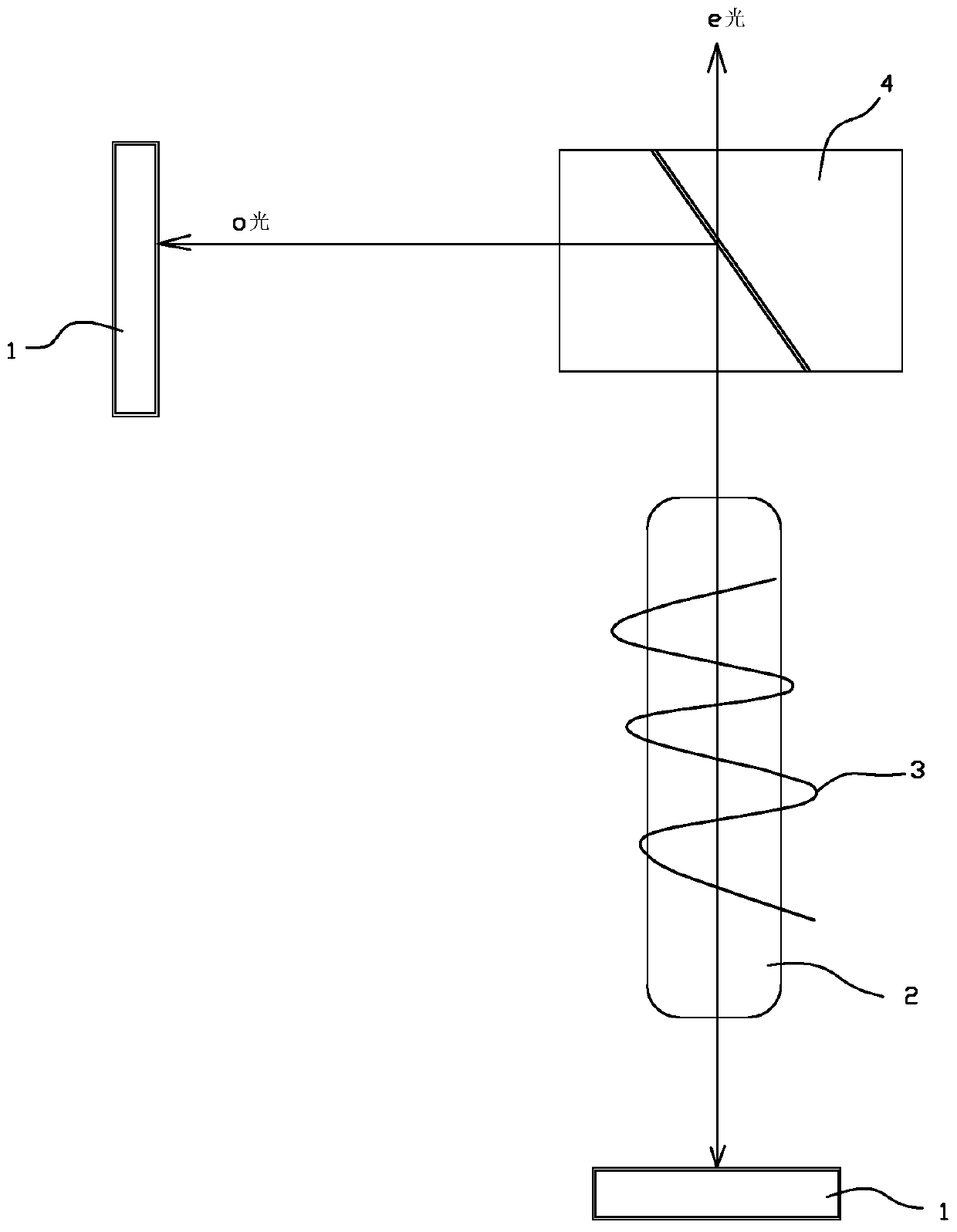

[0040] refer to image 3 As shown, a kind of resonant cavity structure based on the magneto-optical effect provided by the present embodiment includes: two laser high reflection mirrors 1 arranged at intervals and a polarization device and a magnetic field generator ( not shown) and magneto-optical material body 2. Specifically, the resonant cavity is an "L" shaped resonant cavity, two laser high reflection mirrors 1 are respectively arranged at the two ends of the "L" shaped resonant cavity, the polarizing device is a Glan Taylor prism 4, and the Glan Taylor prism 4 is set at the corner position of the "L" shaped resonant cavity. The incident light beam is refracted by the Glan-Taylor prism 4, so as to reflect and oscillate back and forth between the two laser high reflection mirrors 1 to form an oscillating light beam (o-ray in this embodiment).

[0041] The magnetic field generator corresponds to the magneto-optical material body 2, and the magnetic field 3 generated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com