Three-dimensional modeling device and three-dimensional modeling method

A technology for three-dimensional modeling and three-dimensional objects, which is applied in the directions of manufacturing auxiliary devices, processing and manufacturing, and manufacturing tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

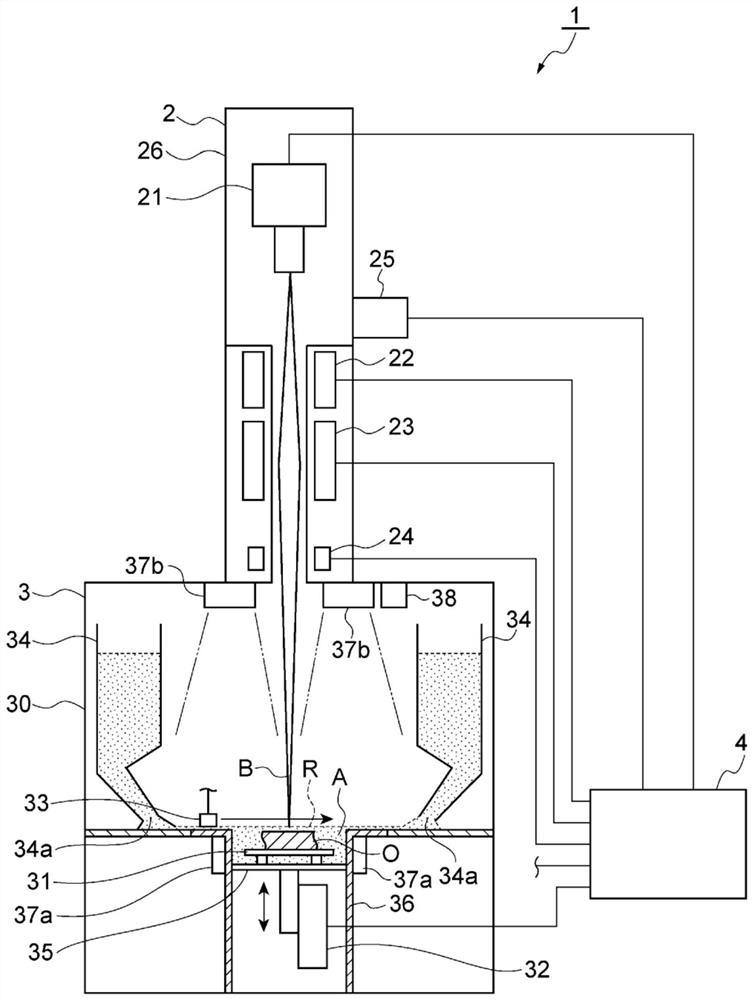

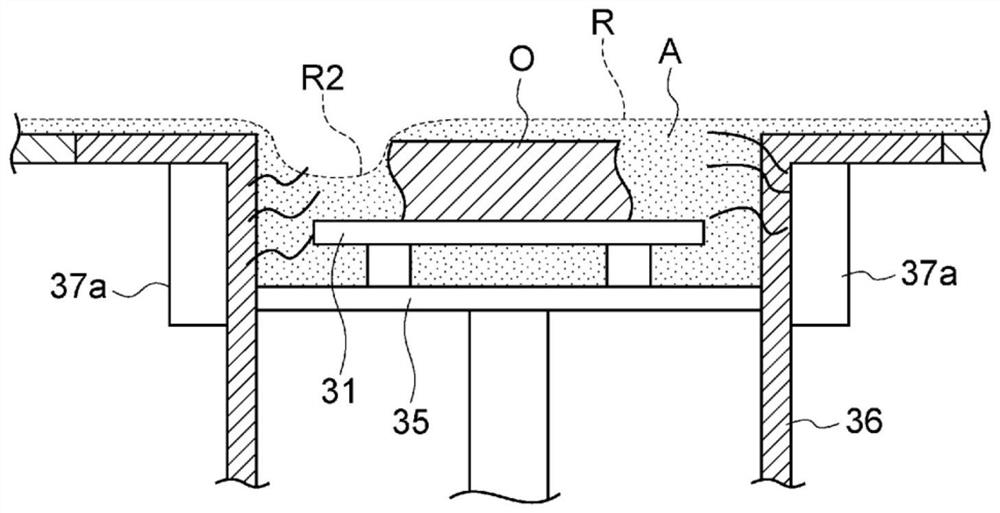

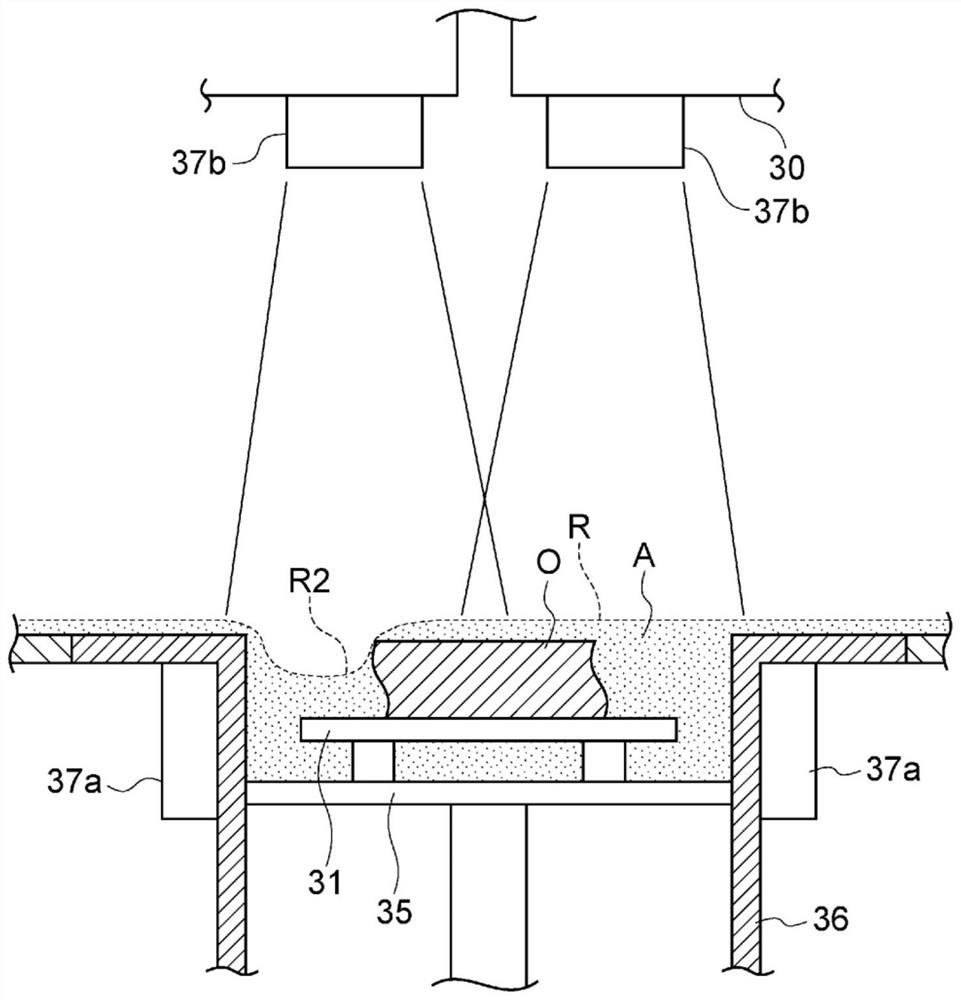

[0018] A three-dimensional modeling device according to one aspect of the present invention supplies and spreads a powder material to an irradiation area of a charged particle beam, irradiates the powder material with a charged particle beam, melts the powder material, and shapes a three-dimensional object. The three-dimensional modeling device includes: a charged particle beam that emits a charged particle beam and irradiates the powder material with the charged particle beam; a detection unit that detects that the powder material is scattered due to the irradiation of the charged particle beam on the powder material; and a heating unit. , which heats the irradiated area. The heating unit heats the irradiated area before supplying new powder material to the irradiated area when it is detected by the detection unit that the powder material is scattered during the modeling of the object. When the powder material is detected to be scattered, the irradiation of the charged part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com