An all-in-one drying and screening machine for crop production

A technology of crops and all-in-one machines, applied in the agricultural field, can solve problems such as affecting agricultural production capacity and poor work continuity, and achieve the effects of avoiding blockage, avoiding pollution, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

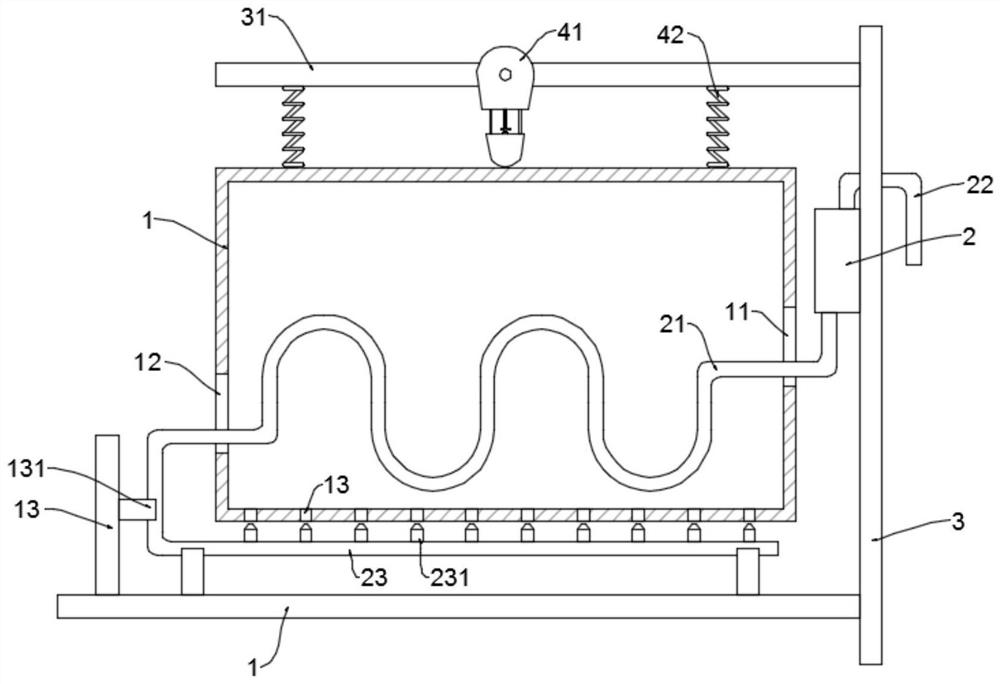

[0024] see Figure 1~3 , in an embodiment of the present invention, an integrated drying and screening machine for crop production, including a box body 1 and a base 6, the bottom of the box body 1 is evenly distributed with sieve holes 13; the box body 1 is located above the base 6 The top of the box body 1 is fixed with a vertical support 3, and the top of the vertical support 3 is fixed with a horizontal support 31. Hot air blower 2; the output end and the input end of described hot air blower 2 are respectively connected with air outlet pipe 21 and air inlet pipe 22, and wherein air outlet pipe 21 stretches in the box body 1, and there are supply outlet pipes on both sides of the box body 1. The inlet 11 and outlet 12 where the air pipe 21 enters and exits. When the vibration drive component drives the box 1 to vibrate to screen crops, the air outlet pipe 21 inside the box 1 will continuously come into contact with the crops, thereby drying the crops. , so that screening ...

Embodiment 2

[0032] see Figure 4~5 The difference between this embodiment of the present invention and Embodiment 1 is that in this embodiment, a filter box 5 is also fixed on the vertical support 3, and the filter box 5 is connected to the air intake pipe 22, so that the filter box 5 can be used to The air extracted by the hot air blower 2 is purified to prevent impurities from polluting the crops in the box body 1 .

[0033] Specifically, in this embodiment, the filter box 5 includes a housing 51 and a filter plate 52 disposed in the housing 51. A slot 511 is integrally formed on the inner wall of the housing 51, and one end of the filter plate 52 is slidably inserted into the Set in the card slot 511 and connected to the inner wall of the housing 51 through the connecting spring 53, the other end of the filter plate 52 slides through the shell wall of the housing 51 and is connected with a pull ring 54; the filter plate 52 is close to the card slot 511 One side is connected with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com