A method for producing 5554 aluminum alloy welding wire by continuous casting and rolling

An aluminum alloy welding wire, continuous casting and rolling technology, applied in welding equipment, welding medium, metal rolling and other directions, can solve the problems of large energy loss, low production efficiency, large diameter deviation, etc. The effect of stable quality and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

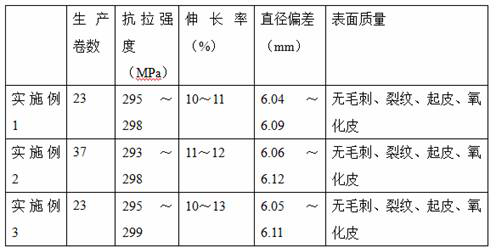

Examples

Embodiment 1

[0035] The method for producing 5554 aluminum alloy welding wire by continuous casting and rolling of the present embodiment is carried out as follows:

[0036] In the tipping smelting furnace, the aluminum liquid with the aluminum content of 99.84% is installed, and the temperature is controlled at 785 ℃; the aluminum liquid with the aluminum content of 99.84% in the tipping smelting furnace is added metal magnesium and 75% chromium agent 75% manganese agent It is alloyed with 75% titanium agent, and the aluminum liquid of Mg: 2.73%; Cr: 0.16%; Mn: 0.92%; Ti: 0.17% is prepared. The molten aluminum was electromagnetically stirred for 26 minutes to make the alloy composition and temperature of the molten aluminum uniform; the molten aluminum was refined by spraying with argon (refining agent) for 21 minutes, and the scum on the surface of the molten aluminum was cleaned up after the refining; , wait for the standing time of 87 minutes and the converter after the temperature mee...

Embodiment 2

[0043] The method for producing 5554 aluminum alloy welding wire by continuous casting and rolling of the present embodiment is carried out as follows:

[0044] A molten aluminum with an aluminum content of 99.82% is placed in the tipping smelting furnace, and its temperature is controlled at 800°C.

[0045] Aluminum liquid alloying, adding metal magnesium, 75% chromium agent, 75% manganese agent and 75% titanium agent to the aluminum liquid with the aluminum content of 99.82% in the tilting melting furnace to prepare Mg: 2.8%; Cr: 0.17% ; Mn: 0.94%; Ti: 0.18% of molten aluminum.

[0046] The molten aluminum was electromagnetically stirred for 25 minutes to make the alloy composition and temperature of the molten aluminum uniform.

[0047] The aluminum liquid is refined, and the argon powder (refining agent) is used for refining for 27 minutes. After the refining is completed, the scum on the surface of the aluminum liquid is removed.

[0048] The molten aluminum converter, ...

Embodiment 3

[0054] The method for producing 5554 aluminum alloy welding wire by continuous casting and rolling of the present embodiment is carried out as follows:

[0055] A molten aluminum with an aluminum content of 99.82% is placed in the tipping smelting furnace, and its temperature is controlled at 790°C.

[0056] Aluminum liquid alloying, adding metal magnesium, 75% chromium agent, 75% manganese agent and 75% titanium agent to the aluminum liquid with the aluminum content of 99.82% in the tilting melting furnace to prepare Mg: 2.67%; Cr: 0.15% ; Mn: 0.94%; Ti: 0.18% of molten aluminum.

[0057] The molten aluminum was electromagnetically stirred for 23 minutes to make the alloy composition and temperature of the molten aluminum uniform.

[0058] The aluminum liquid is refined, and it is refined with argon powder (refining agent) for 24 minutes. After the refining is completed, the scum on the surface of the aluminum liquid is cleaned up.

[0059]The molten aluminum converter, wai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com