Honeycomb paper core cutting device

A honeycomb paper core and cutting technology, which is applied in metal processing and other directions, can solve the problems of unfavorable enterprise development and increase of enterprise purchase cost, and achieve the effect of cost saving and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

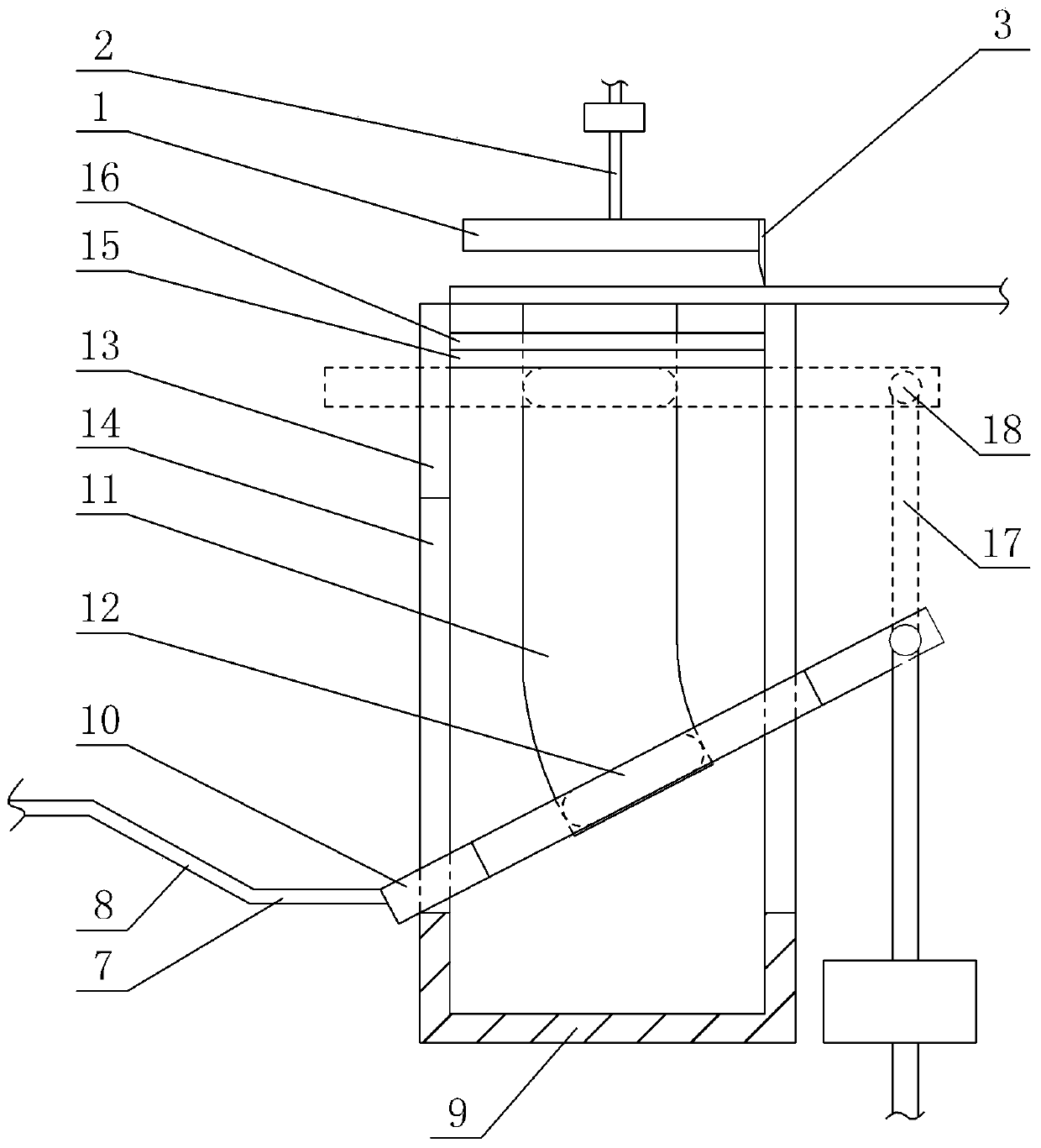

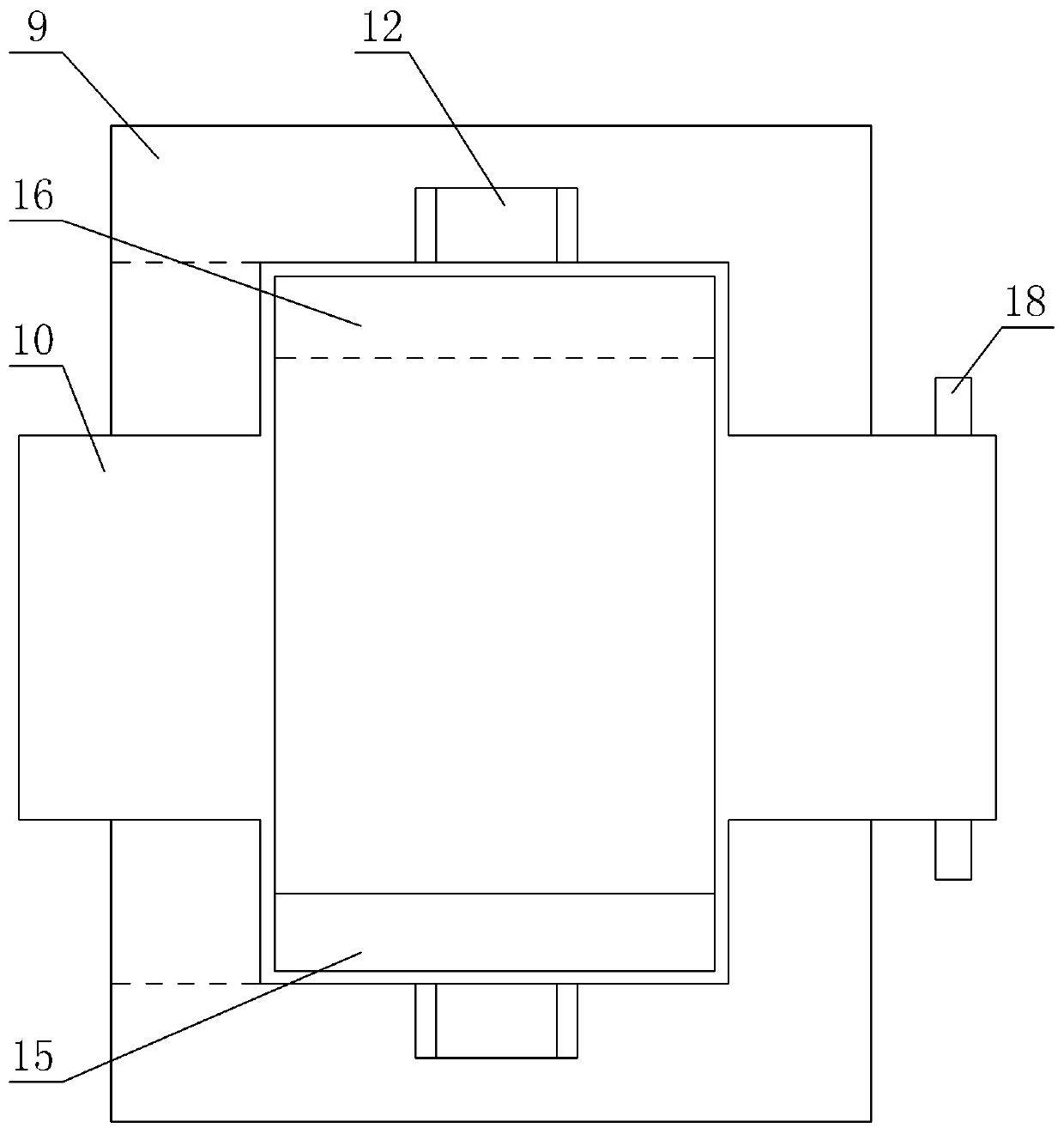

[0023] Embodiment 1 is basically as attached Figure 1-3 Shown: as figure 1 The honeycomb paper core cutting device shown includes a frame, a pressing box 1, a driving mechanism and a feeding mechanism. The motor is fixed on the frame by bolts, the turntable is welded coaxially with the output shaft of the servo motor, and a toggle rod is eccentrically welded on the turntable; the lifting rod 2 is slidably set on the frame, and the lower end of the lifting rod 2 is welded to the pressing box 1. The right side wall of the pressing box 1 is welded with a cutting knife 3; one end of the connecting rod is hinged with the toggle lever through a pin, and the other end of the connecting rod is also hinged with the upper end of the elevating rod 2 through a pin.

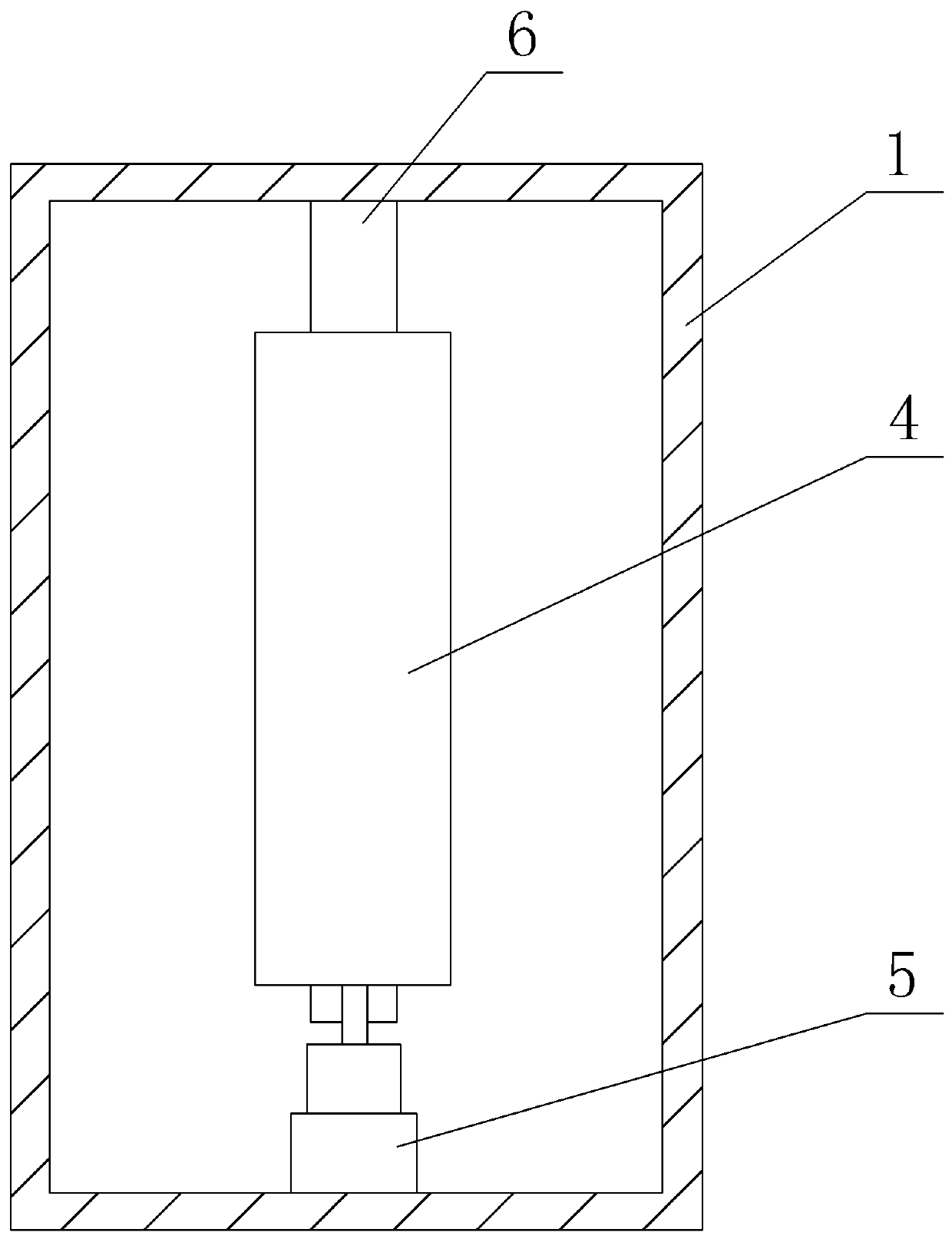

[0024] Press box 1 is provided with such as figure 2 As shown in the suction box 4, the suction box 4 is placed in the pressing box 1, and a negative pressure fan is installed in the suction box 4 through bolts, and the n...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 As shown, the feeding mechanism also includes a support rod 17, a round hole is provided on the frame, the support rod 17 is slidably arranged in the round hole, and a rubber pad is glued on the support rod 17. The support plate 10 is provided with a through hole, and a rotating rod 18 is arranged for rotation in the through hole, and the upper end of the supporting rod 17 is welded with the rotating rod 18 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap