Composite plate structure and box structure thereof

A technology for composite plates and boxes, applied in rigid containers, flexible coverings, containers, etc., can solve the problems of reduced state and strength, complicated manufacturing process, weak resistance to moisture of boxes, etc., and achieves manufacturing cost and material cost. Lowering, stable structure and strength, and the effect of being conducive to repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

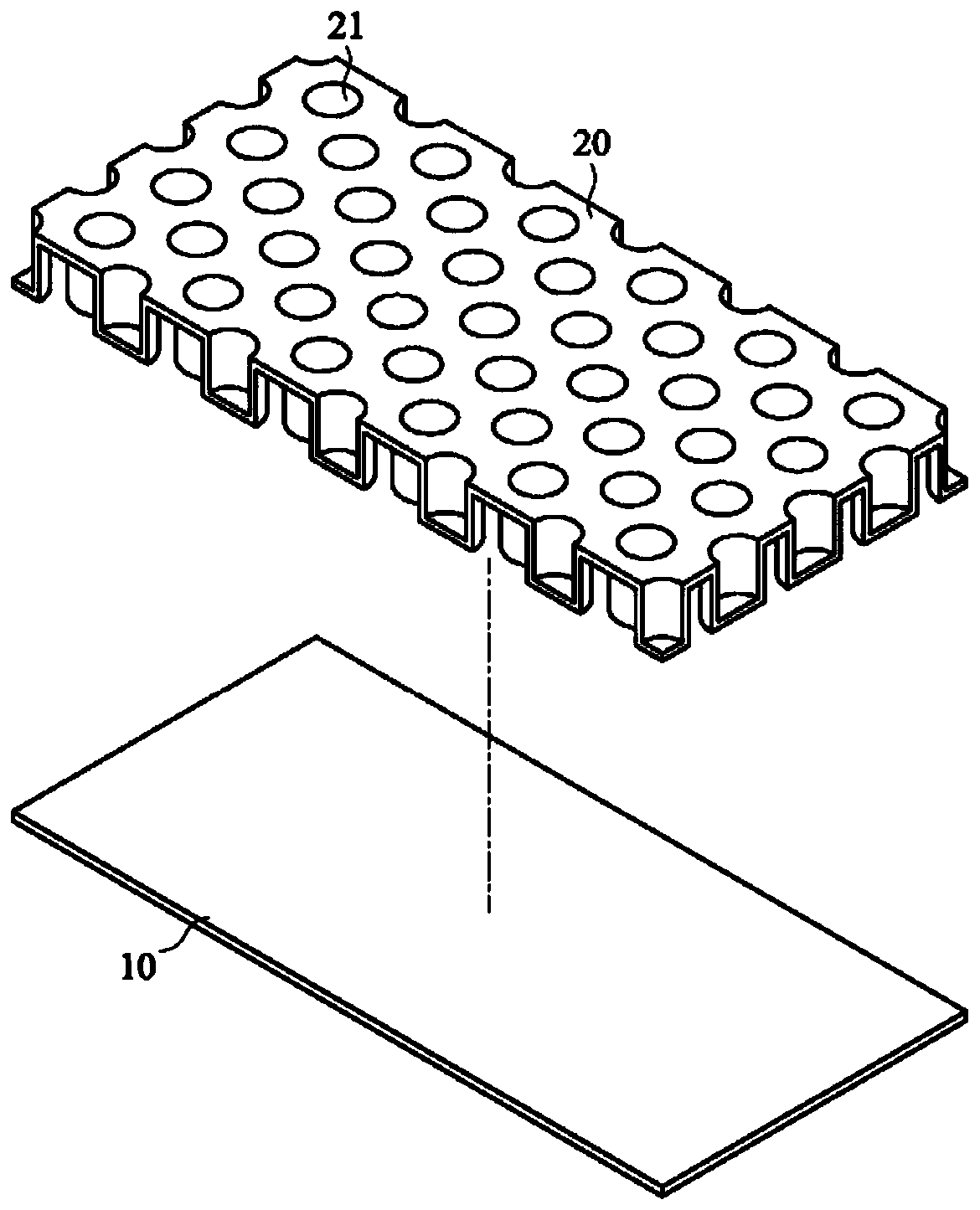

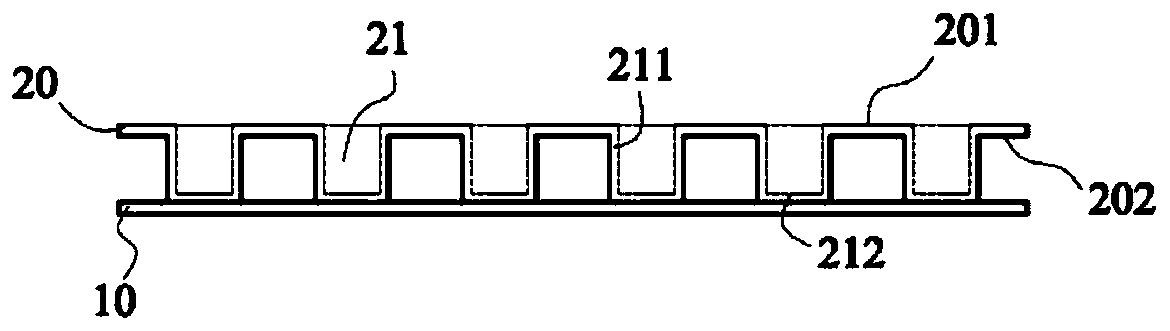

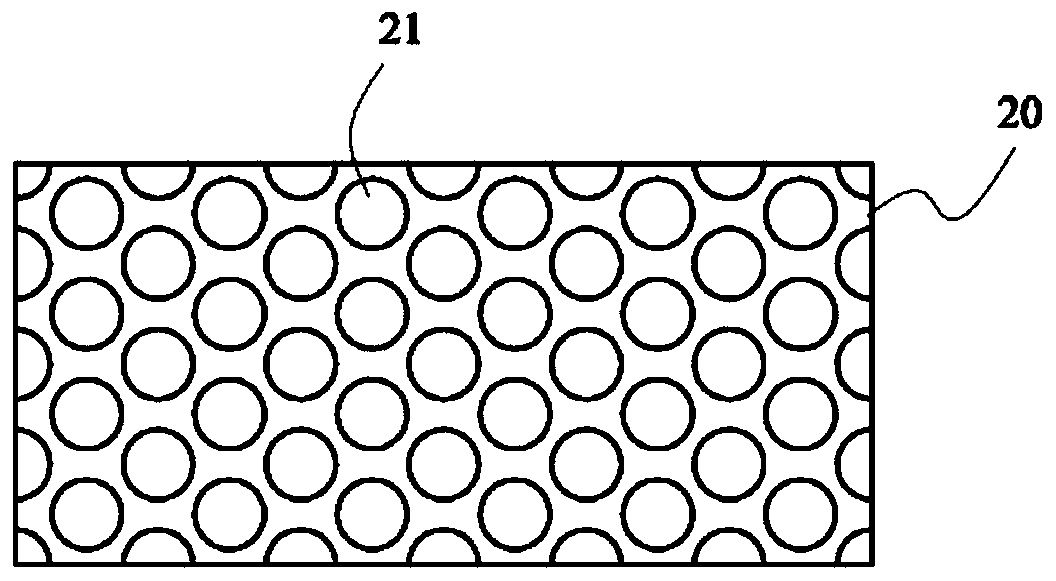

[0041] According to the disclosed composite plate structure and its box structure of the present invention, first please refer to Figure 1A , Figure 1B , the composite plate structure includes a supporting base plate 10 and a structural plate 20, the supporting base plate 10 is slightly flat, and the structural plate 20 has a plurality of pits 21, so the plate side 201 and the pits are defined on the structural plate 20 side 202, and the pit 21 will include a pit wall 211 and a pit bottom 212 according to its structure; Various methods such as bonding, ultrasonic bonding, thermocompression bonding, snap-fitting, etc., mainly depend on the material and the occasion of use; but the above are only examples, and are not limited to these methods. The material can be plastic, paper, foam material, polymer material, metal, or a combination of more than one of the above materials.

[0042] Therefore, the composite plate formed after the support base plate 10 and the structural pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com