A kind of preparation method of low refractive index fluorine-containing styrene dimer chain transfer agent

A styrene dimer chain and low refractive index technology, which is applied in the field of preparation of low refractive index fluorine-containing styrene dimer chain transfer agents, can solve the problem of poor molecular weight adjustment effect, poor product miscibility, and sensitive addition amount and other problems to achieve the effect of overcoming expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

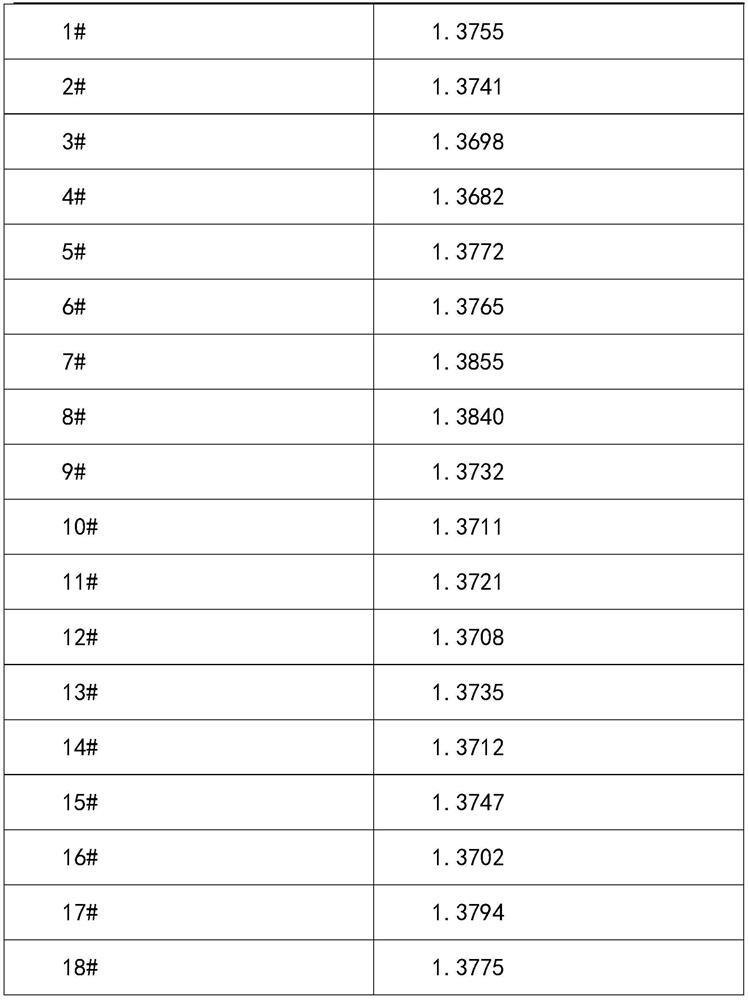

Examples

Embodiment 1

[0022] Preparation of fluorine-containing styrene dimer chain transfer agent: Add 40g of styrene dimer and 100g of butyl acetate into the reactor, heat up and stir, raise the temperature to 121°C and keep it for 0.5h, add benzoyl peroxide, drop Add 20gG01, drop it for 3 hours, keep it warm for 3 hours, lower the temperature to 70°C, and vacuum it for 1 hour, the vacuum pressure is 0.06Mpa-0.07Mpa, and the material is discharged to obtain the fluorine-containing styrene dimer chain transfer agent number Y-1.

Embodiment 2

[0024] Preparation of fluorine-containing styrene dimer chain transfer agent: Add 60g of styrene dimer and 100g of butyl acetate into the reactor, heat up and stir, raise the temperature to 121°C and keep it for 0.5h, add benzoyl peroxide, drop Add 20gG03, drop it for 3 hours, keep it warm for 3 hours, lower the temperature to 70°C, reduce the pressure and vacuum for 1 hour, the vacuum pressure is 0.06Mpa-0.07Mpa, and the material is discharged to obtain the fluorine-containing styrene dimer chain transfer agent number Y-2.

Embodiment 3

[0026] Preparation of fluorine-containing styrene dimer chain transfer agent: add 55g styrene dimer and 100g butyl acetate into the reactor, heat up and stir, raise the temperature to 121°C and keep it for 0.5h, add benzoyl peroxide, drop Add 35gG01, drop it for 3 hours, keep it warm for 3 hours, lower the temperature to 70°C, reduce the pressure and vacuum for 1 hour, the vacuum pressure is 0.06Mpa-0.07Mpa, and the material is discharged to obtain the fluorine-containing styrene dimer chain transfer agent number Y-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com