A sand removal and homogenization device suitable for anaerobic fermentation slurry and its process

An anaerobic fermentation and slurry technology, which is applied to specific-purpose bioreactors/fermenters, fermentation, biochemical cleaning devices, etc., can solve the problems of accumulation of impurities in anaerobic fermentation tanks, reduction of anaerobic biogas production rate, Conveying pump wear and other problems, to achieve the effect of prolonging the use and maintenance time, compact device structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

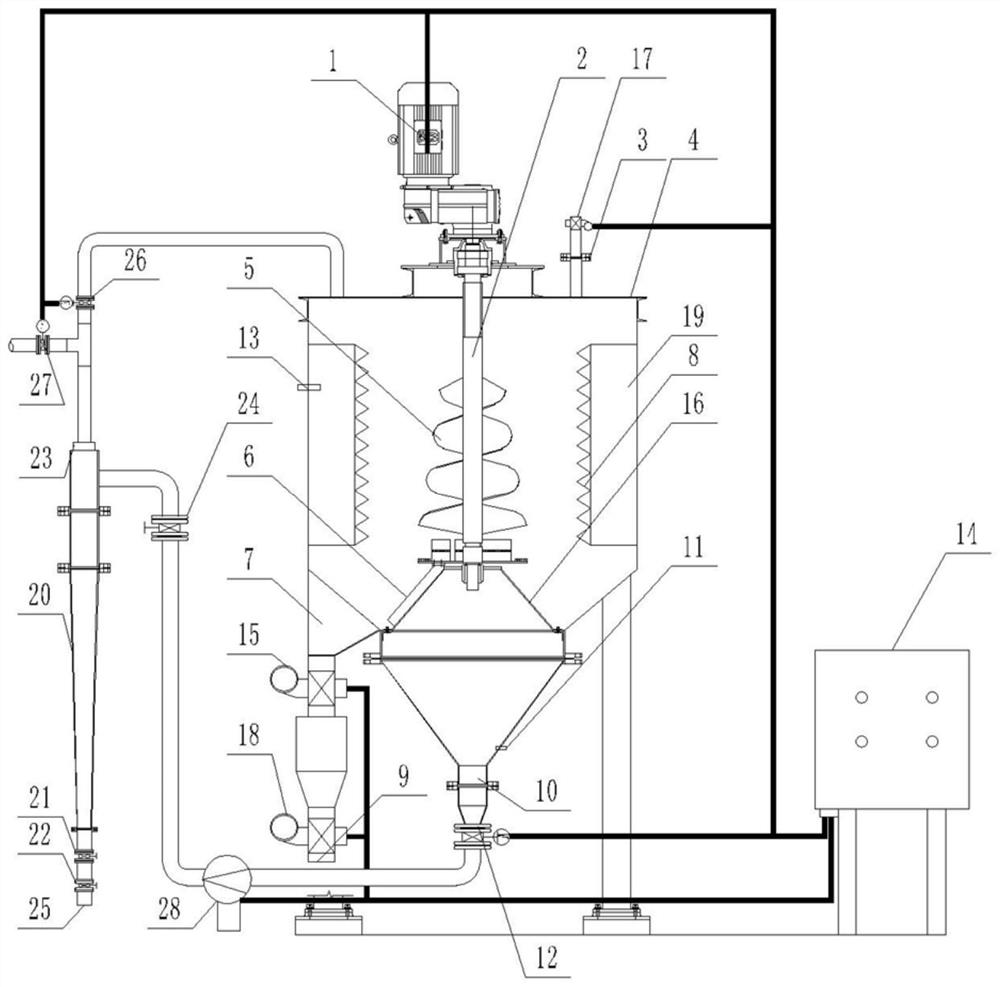

[0032] like figure 1As shown, a desanding and homogenizing device suitable for anaerobic fermentation slurry comprises a desanding tank 4, a driving device 1 is arranged above the desanding tank 4, a transmission shaft 2 is connected below the driving device 1, and the lower part of the transmission shaft 2 There is a swirl stirring paddle 5, which is located in the middle of the sand removal tank 4, and the top of the sand removal tank 4 is communicated with the feed port 3 with the feeding valve group 17, and the bottom of the sand removal tank 4 is connected. There is a filter screen 16 in the center of the filter screen, and a screen cleaner 6 is arranged on the filter screen 16; The rear end of the slurry outlet 10 is connected to the swirl desanding section 20 by a pump 28. The swirl desanding section 20 is communicated with the desanding tank 4 through the upper discharge port 23 and the return valve 26. The upper discharge port 23 and the return flow A bypass with a d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap