Material circulation type flexible stator assembling machine

A material circulation and stator group technology, which is used in the manufacture of stator/rotor bodies, electromechanical devices, electric components, etc., can solve the automatic production work that cannot be competent for multi-variety and small batch production, and the software and hardware such as manipulators cannot be easily changed and assembled. Poor timeliness, assembly temperature and other issues, to achieve the effect of high-precision fully automated production, reasonable internal structure design and layout, and improved assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

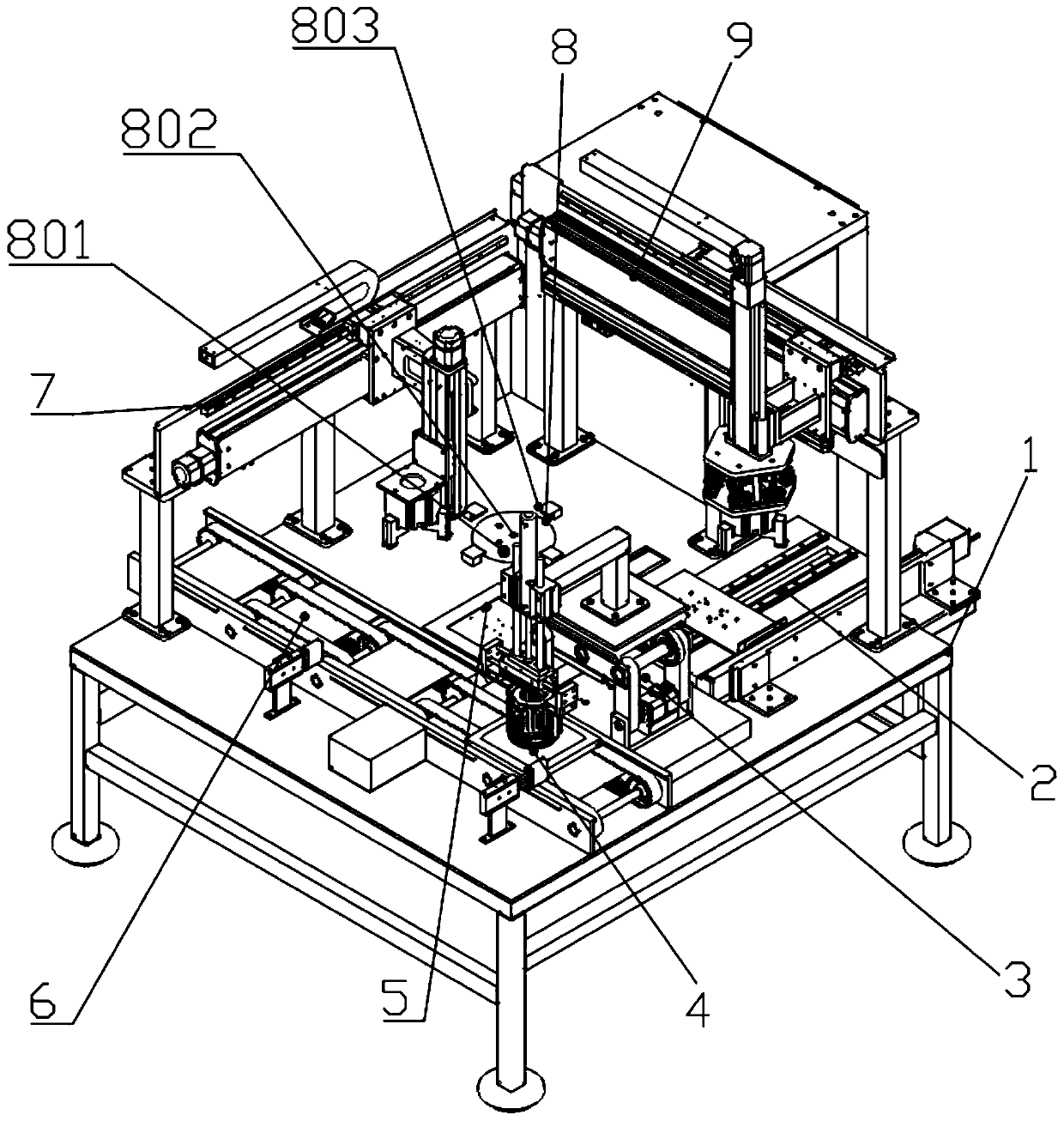

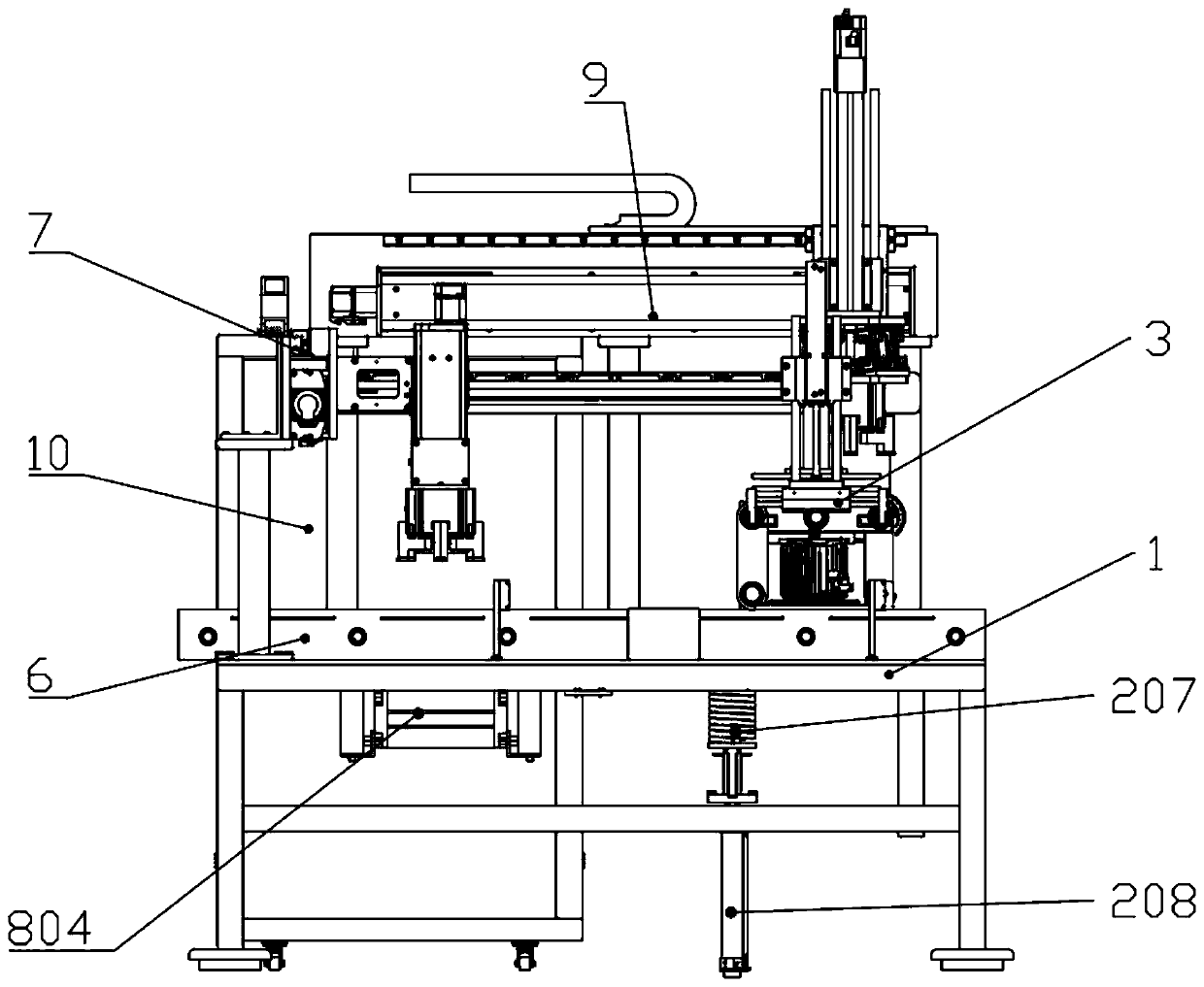

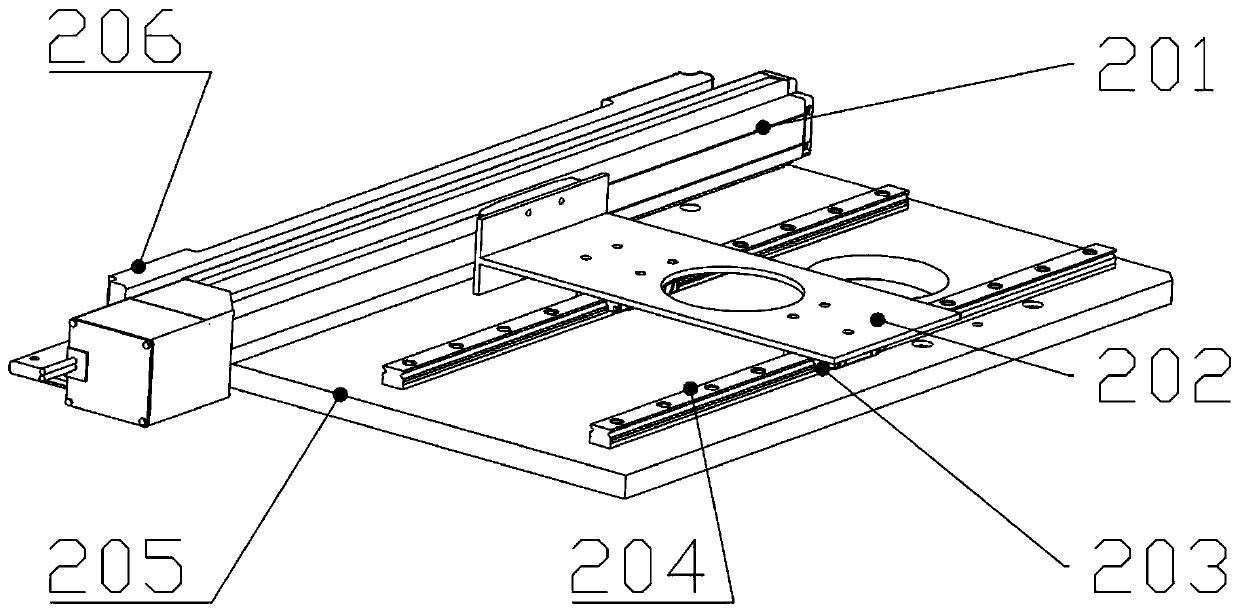

[0051] The invention provides a material circulation type flexible stator assembly machine (referred to as assembly machine, see Figure 1-15 ), including a frame 1; it is characterized in that the assembly machine also includes a casing feeding mechanism 2, a rotating lifting mechanism 3, an accompanying fixture 4, a feeding mechanism 5, a synchronous belt feeding mechanism 6, a stator handling mechanism 7, and a fixing mechanism 8 and the casing transporting and pressing mechanism 9; the casing loading mechanism 2, the rotary lifting mechanism 3, the unloading mechanism 5, the synchronous belt feeding mechanism 6, the stator handling mechanism 7, the fixing mechanism 8 and the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com