Catalyst ignition stage torque distribution method, system and device

A technology of torque distribution and catalytic converter, applied in transportation and packaging, combustion engines, internal combustion piston engines, etc., can solve the problems of accelerated catalytic converter aging, high CO and HC emissions, battery feeding, etc., to improve fuel economy, The effect of avoiding long heating time and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

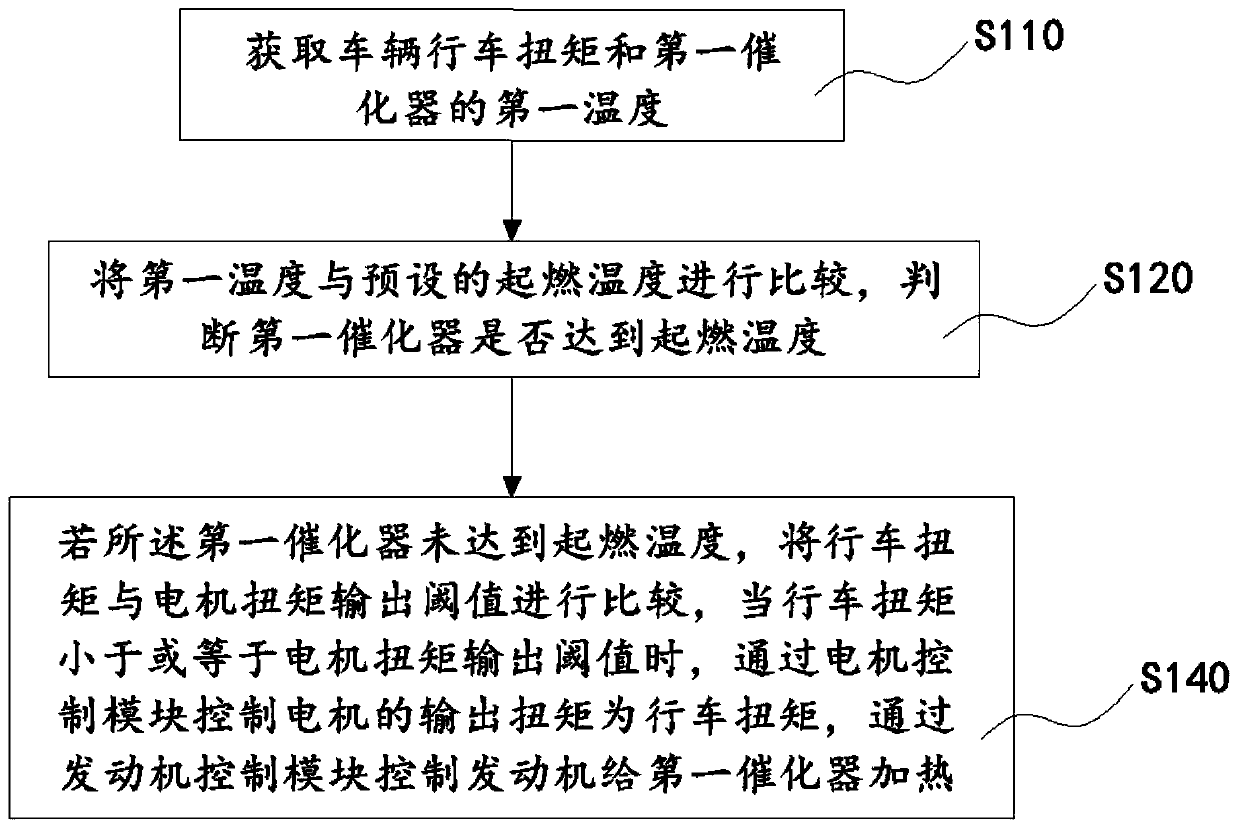

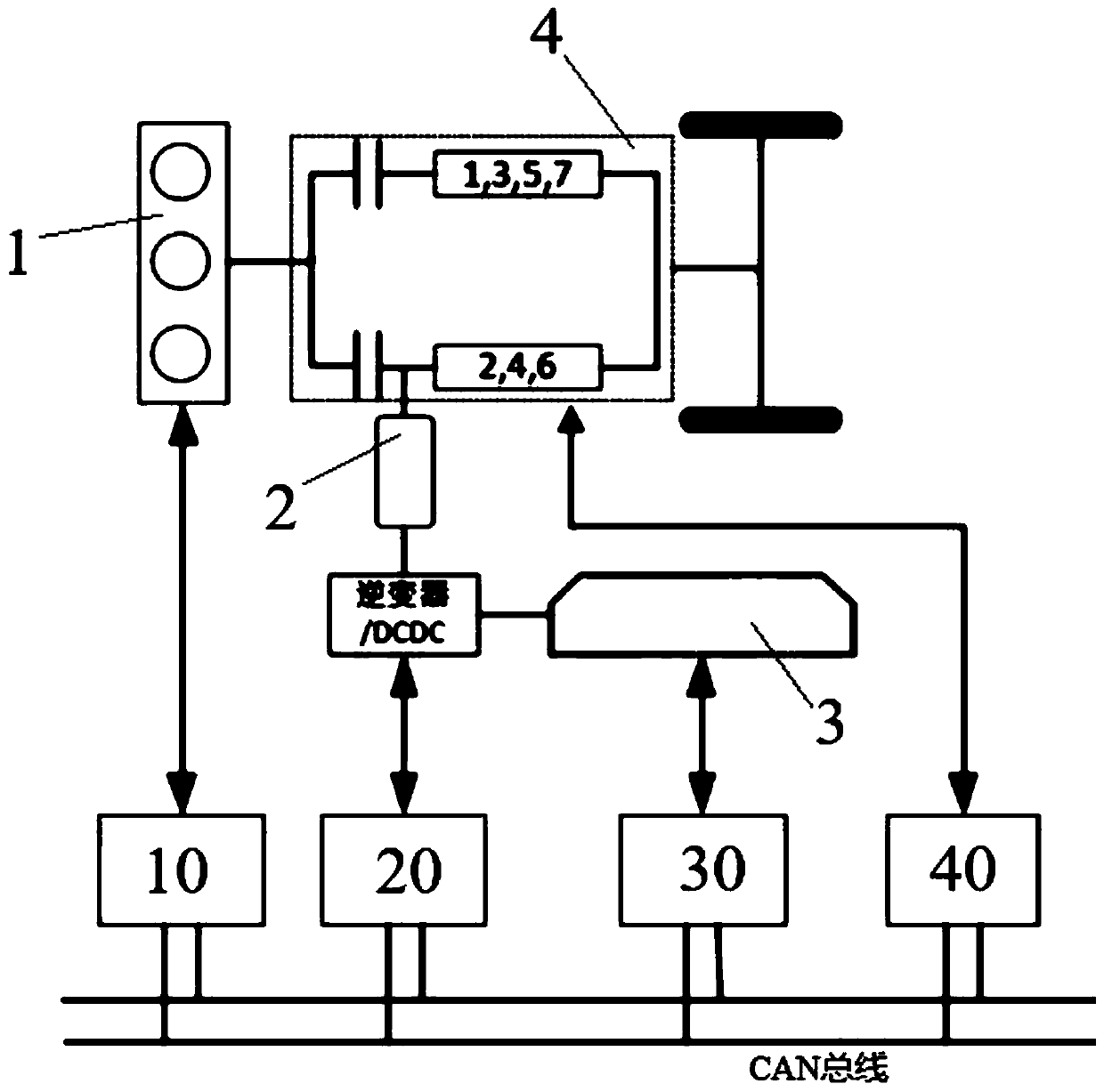

[0061] Please refer to figure 1 with image 3 , the embodiment of this specification provides a torque distribution method for catalytic converter light-off phase, the method is applied to a hybrid vehicle, the hybrid vehicle includes an engine 1, a motor 2, a battery 3 and a transmission clutch 4, the hybrid The vehicle also includes a control system and an exhaust system, the control system includes an engine control module 10 and a motor control module 20, the exhaust system includes an exhaust pipe and a first catalytic converter, and the exhaust pipe is connected to the exhaust pipe of the engine 1 The first catalytic converter is arranged on the exhaust pipe, and the first catalytic converter is connected to the exhaust pipe for purifying CO, HC and NOx in the exhaust gas produced by the engine operation and other harmful gases, the methods include:

[0062] S110: Acquiring the driving demand torque of the vehicle and the first temperature of the first catalytic conver...

Embodiment 2

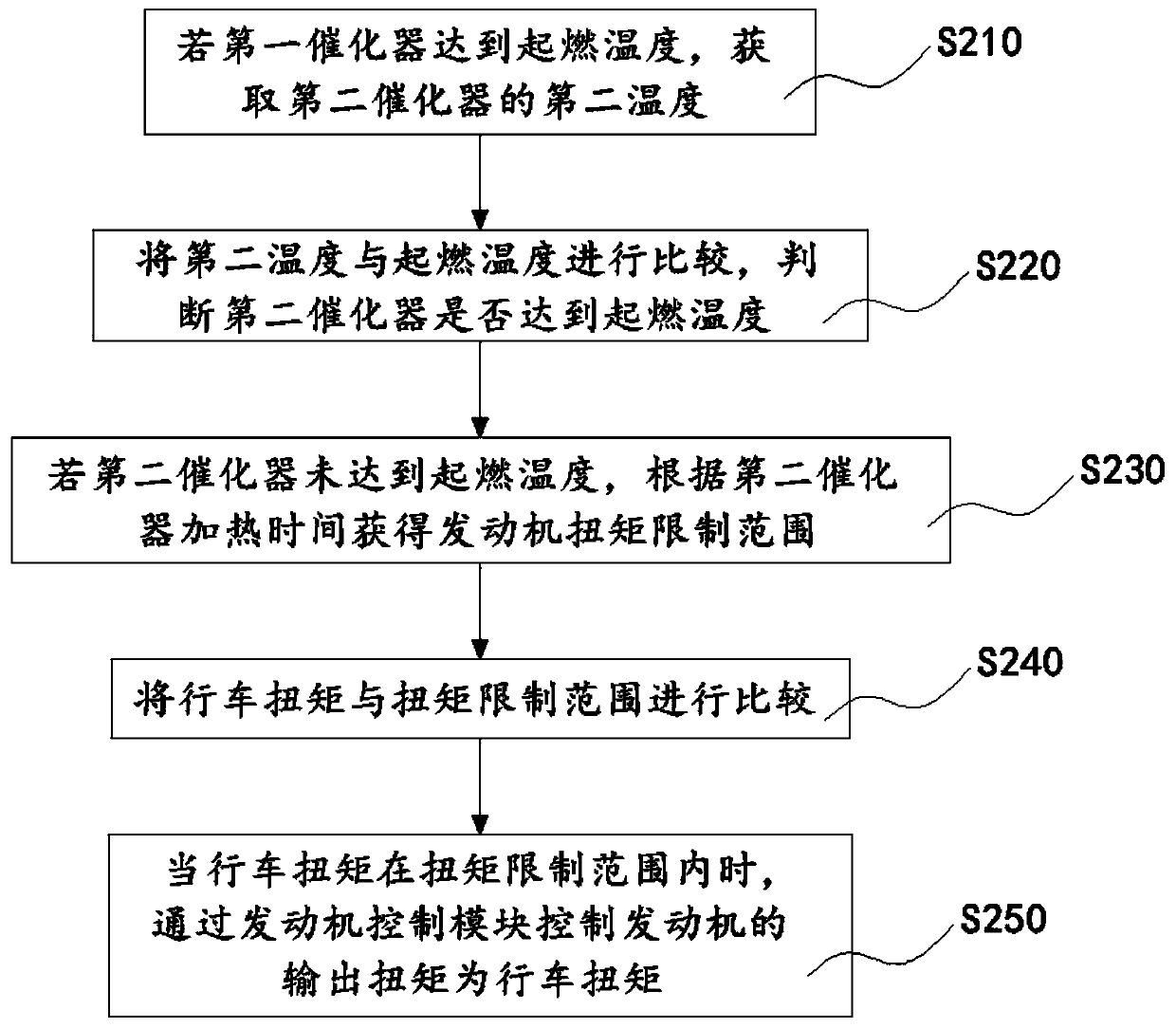

[0077] Please refer to figure 2 with image 3 , the embodiment of this specification provides a torque distribution method in the light-off stage of the catalytic converter. The torque distribution method provided by this embodiment is applied to a hybrid vehicle including a control system and an exhaust system. The difference between this embodiment and Embodiment 1 is: The exhaust system further includes a second catalytic converter, the second catalytic converter is disposed on the exhaust pipe, and the second catalytic converter is disposed on a side of the first catalytic converter away from the exhaust port of the engine. side, that is, the exhaust gas discharged from the engine exhaust port first passes through the first catalytic converter and then passes through the second catalytic converter, so that the unpurified exhaust gas of the first catalytic converter reaches the second catalytic converter through the exhaust pipe. At the catalytic converter, further purifi...

Embodiment 3

[0110] The embodiment of this specification provides a torque distribution system in the light-off stage of the catalytic converter, including:

[0111] a first acquiring unit, configured to acquire the vehicle running demand torque and the first temperature of the first catalytic converter;

[0112] a first judging unit, configured to compare the first temperature with a preset light-off temperature, and judge whether the first catalytic converter has reached the light-off temperature;

[0113] A first control unit, configured to compare the driving demand torque with a motor torque output threshold when the first catalytic converter has not reached the light-off temperature, and when the driving demand torque is less than or equal to the motor torque output threshold , the output torque of the motor is controlled to be the driving demand torque by controlling the motor control module, and the engine is controlled by the engine control module to heat the first catalytic conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com