Walking robot control method and system

A technology of walking robot and control method, which is applied in control/adjustment system, two-dimensional position/channel control, non-electric variable control, etc., can solve the problems of insufficient work area traversal and repetitive work, and achieve improved ergodicity, The effect of improving work efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

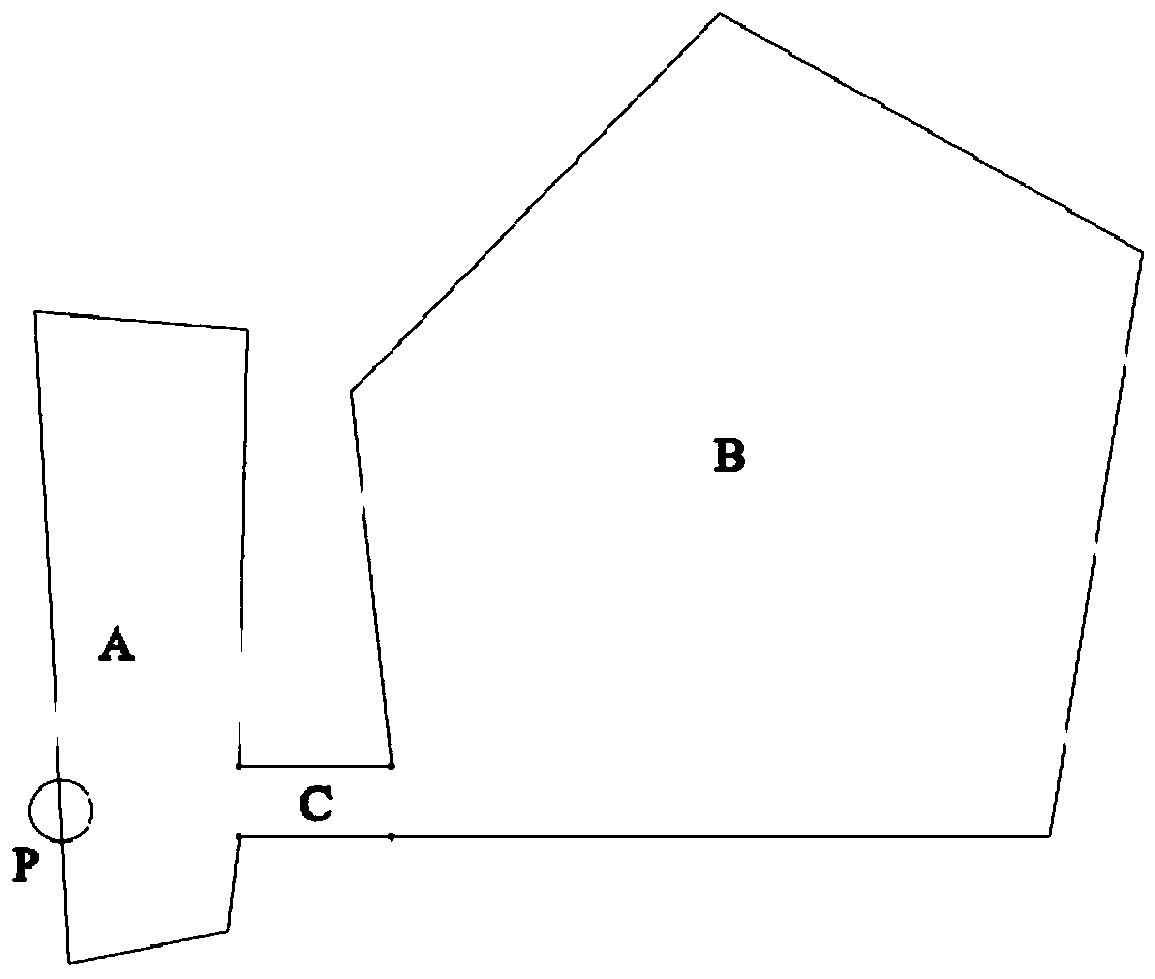

[0030] The walking robot of the present invention can be an automatic lawn mower, or an automatic vacuum cleaner, etc., which automatically walks in the working area to perform work such as mowing and vacuuming. In the specific example of the present invention, a lawnmower is used as an example for the specific description. Correspondingly, the working area may be a lawn. Of course, walking robots are not limited to lawn mowers and vacuum cleaners, and can also be other equipment, such as spraying equipment, snow removal equipment, monitoring equipment, etc., which are suitable for unattended equipment.

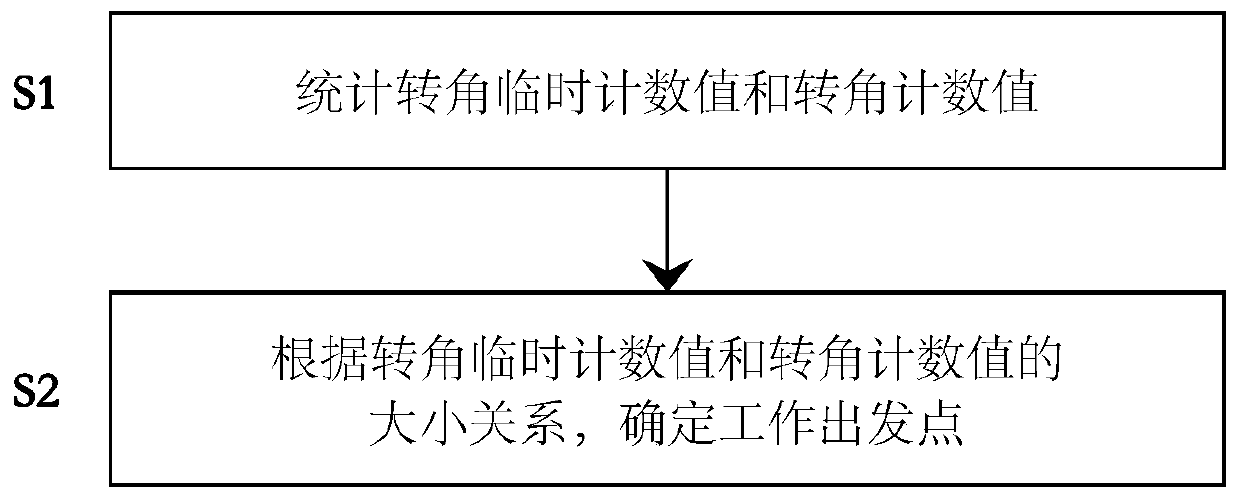

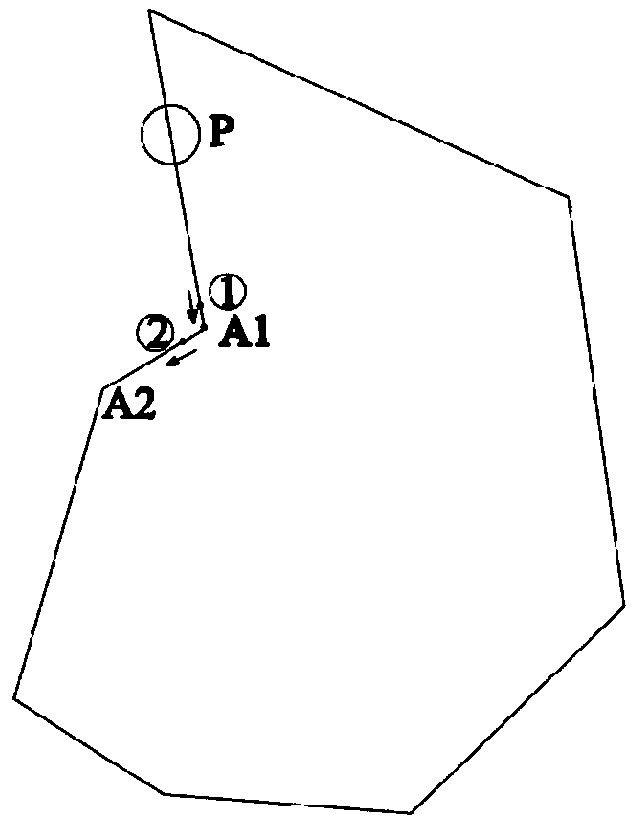

[0031] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com