Converter steelmaking online monitoring and early warning system and method based on cloud platform

A converter steelmaking and early warning system technology, applied in the transmission system, closed-circuit television system, alarm, etc., can solve the problems of lack of scientific and systematic real-time monitoring system, prone to safety accidents, and no forming system, etc., to improve the enterprise Scientific and intelligent management level, strong scalability, and the effect of saving monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

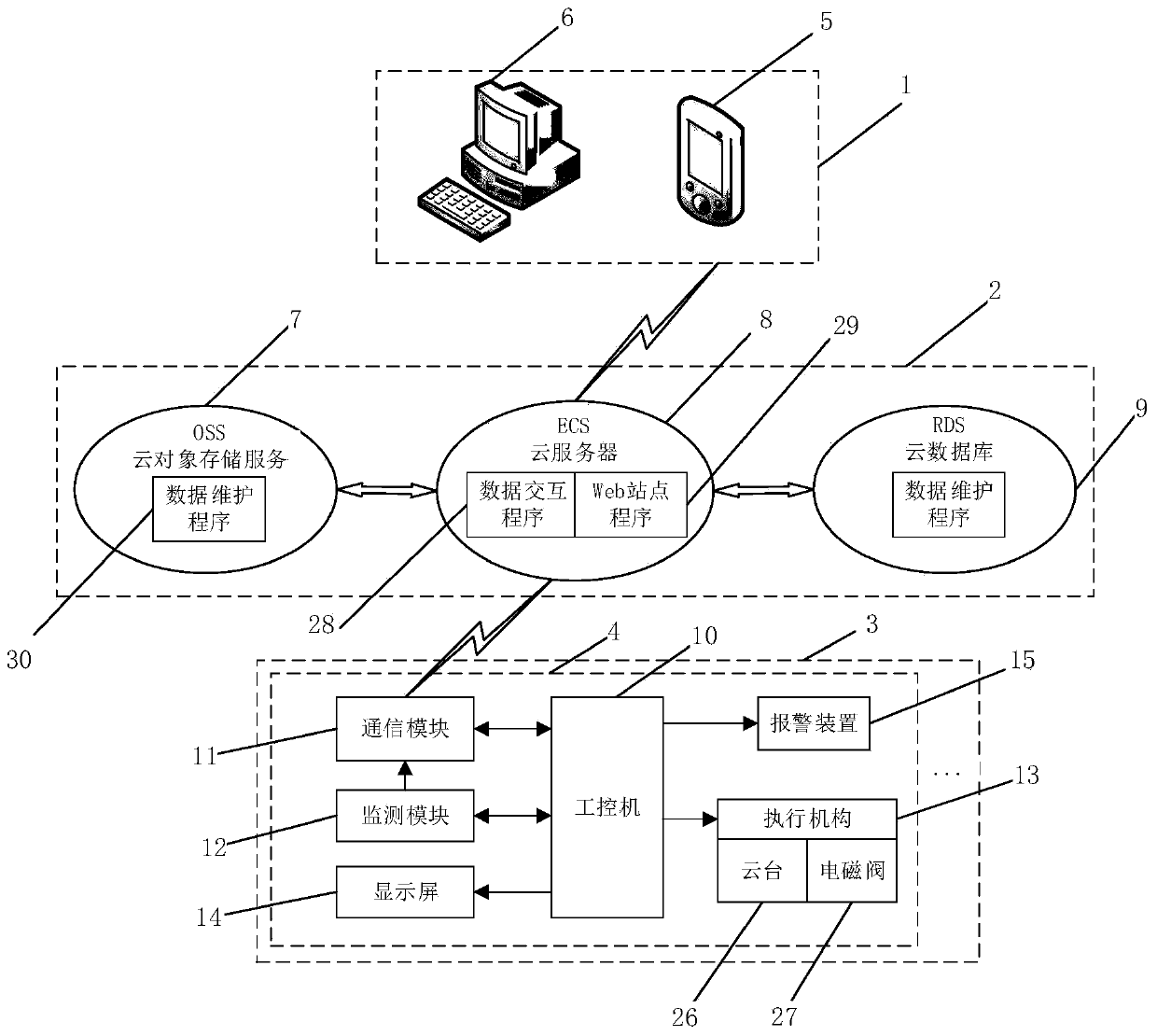

[0034] to combine figure 1 , the present invention is an online monitoring and early warning system for converter steelmaking based on a cloud platform, including a user mobile terminal 1, a cloud platform 2 and an environmental information collection and processing system 3;

[0035] Described user mobile terminal 1 comprises mobile terminal 5 and PC6;

[0036] Described cloud platform 2 comprises cloud server ECS8, cloud database 9 and cloud object storage 7;

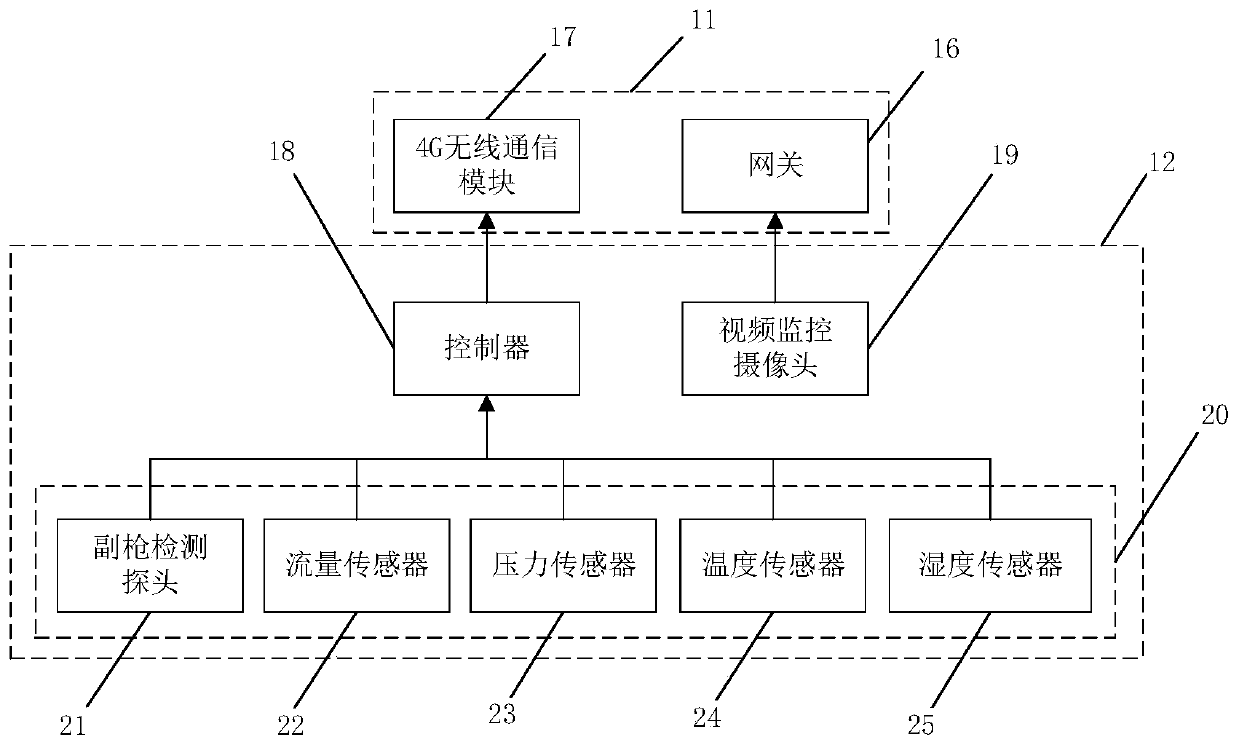

[0037] Described environmental information collection and processing system 3 is made up of a plurality of enterprise nodes 4, and each enterprise node 4 comprises industrial computer 10, and the communication module 11 that links to each other with industrial computer 10, executive mechanism 13, display screen 14, alarm device 15, and A monitoring module 12 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com