Distributed exposure dose control system and method

A technology of exposure dose and control system, applied in the field of integrated circuit equipment manufacturing, which can solve the problems of inaccurate compensation, time lag, and dependence on accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0069] The present invention is an implementation system of an exposure dose control system and related methods. The following describes the detailed implementation cases of related structures and steps of the present invention.

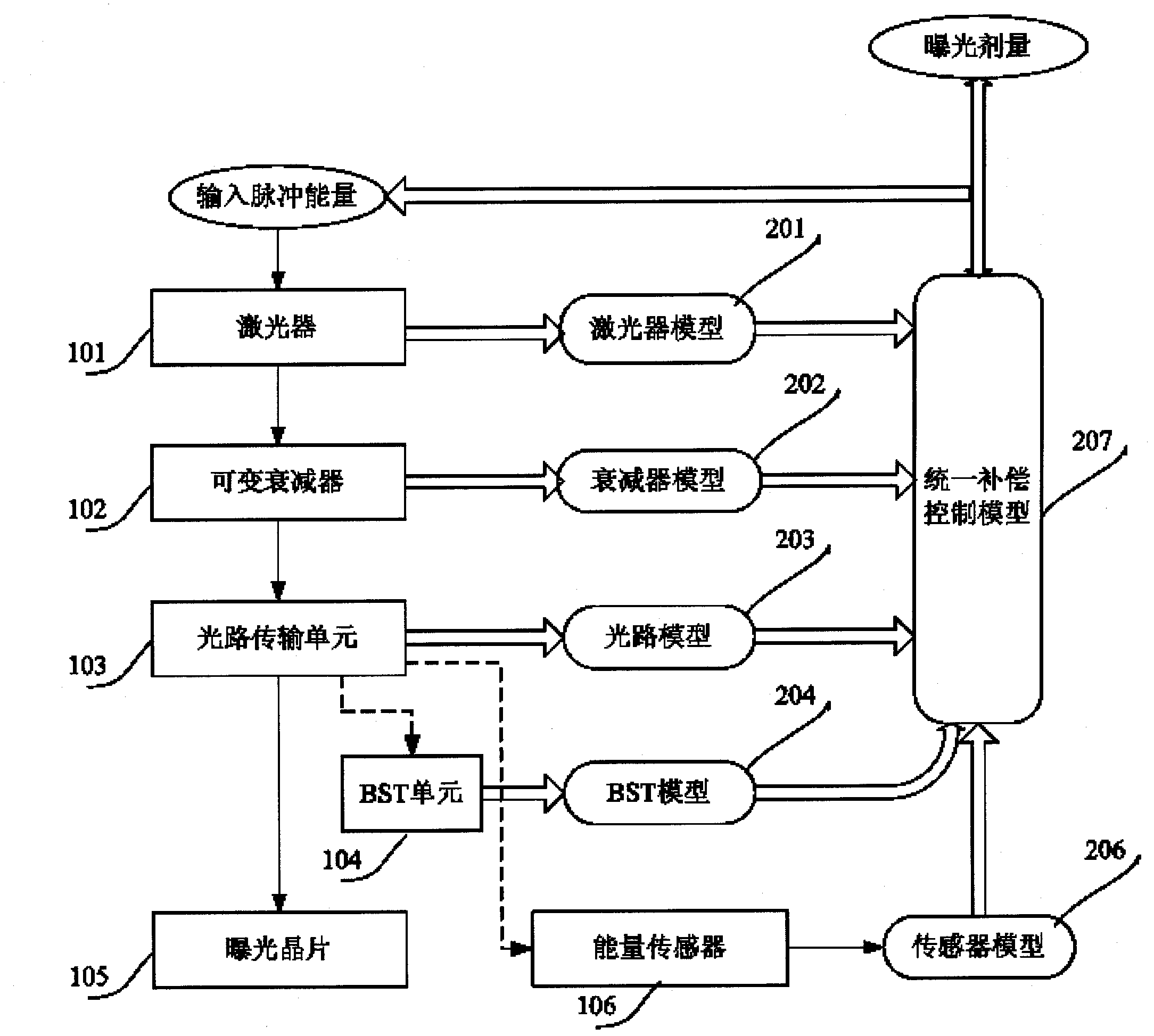

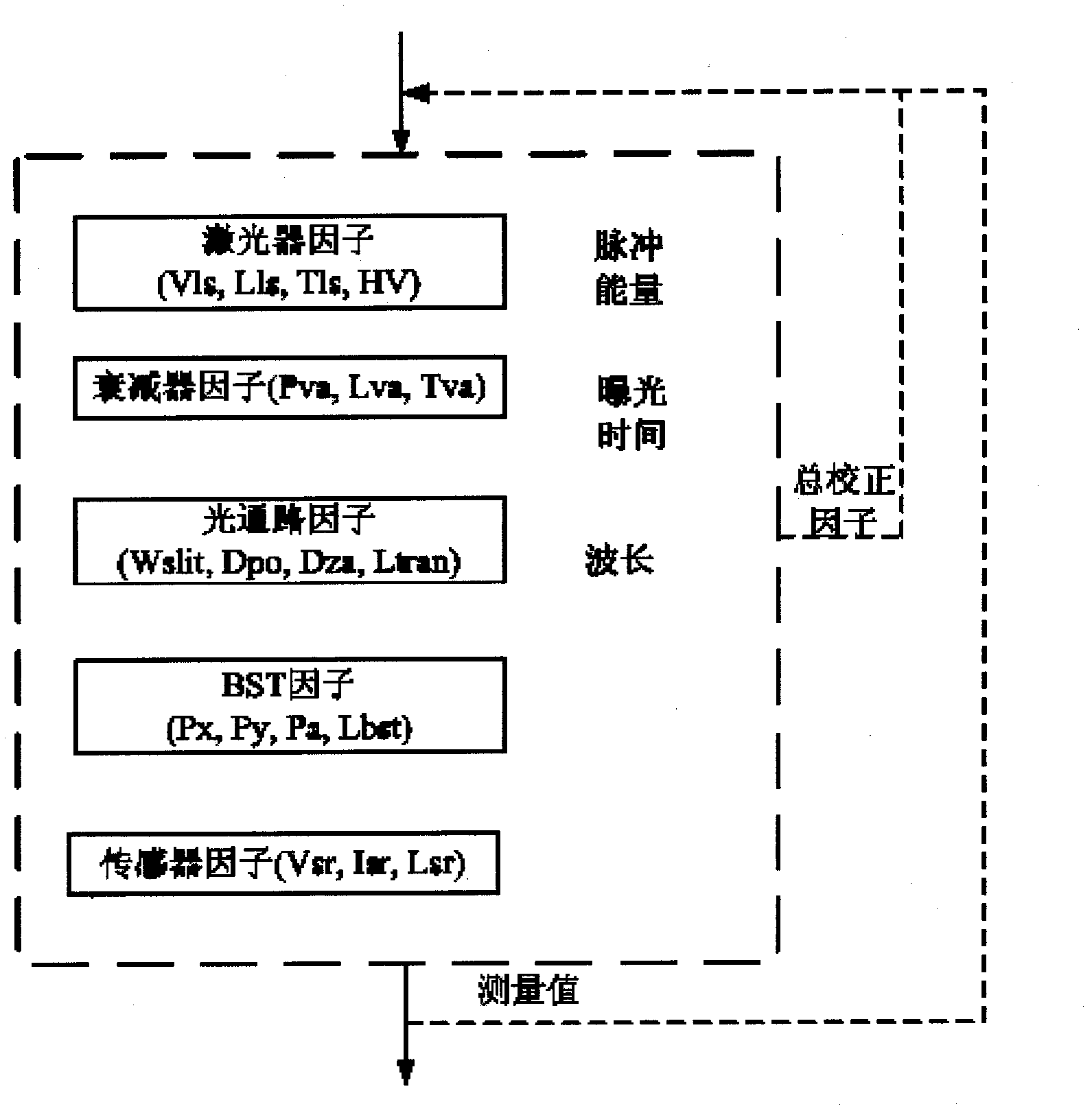

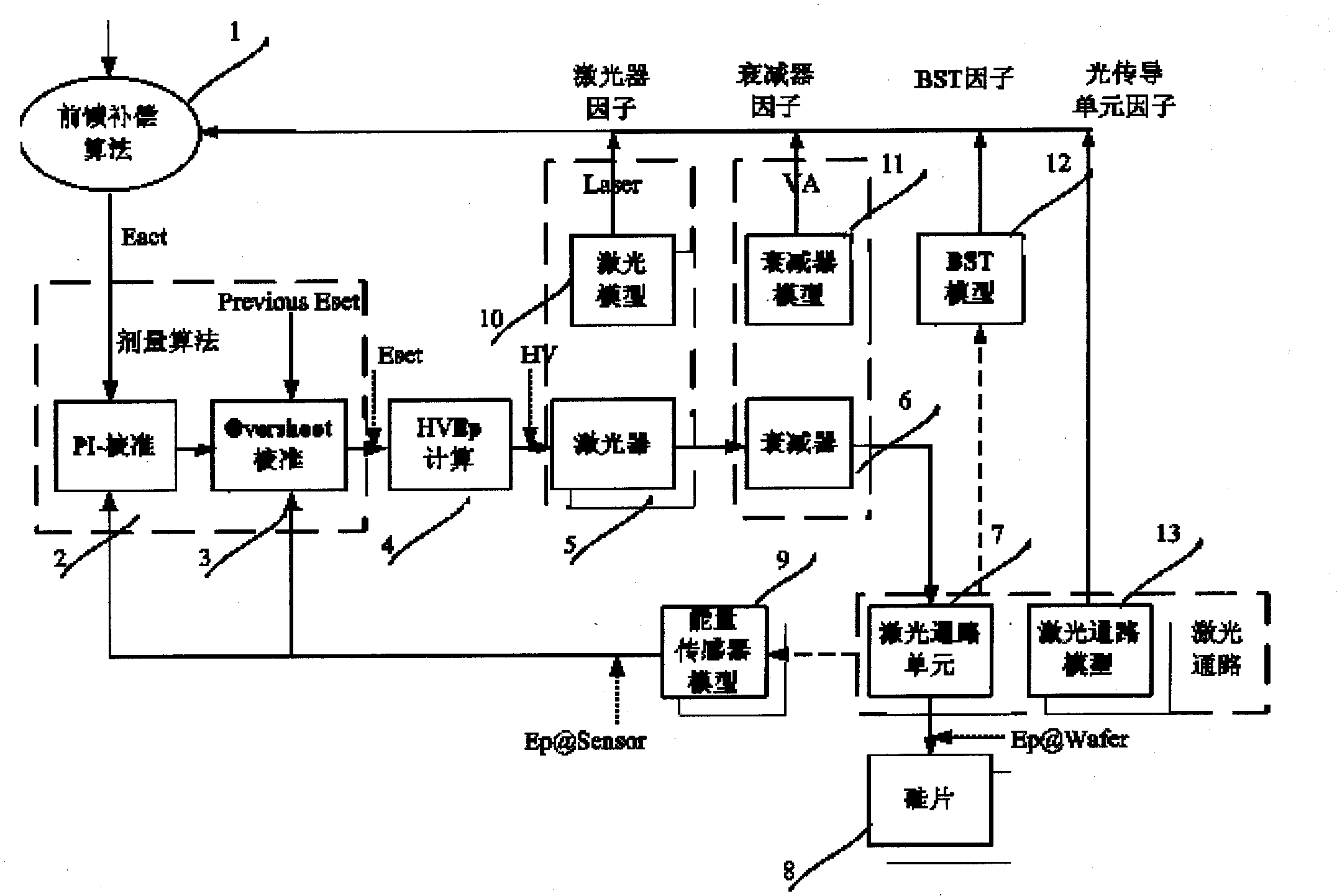

[0070] The method is based on an exposure dose control system, so first a brief description of the exposure dose control system is given. Such as figure 1 As shown, the input pulse energy value is first sent to the laser 101, and then the laser triggers the laser pulse. After the laser pulse is sent out, it will pass through the variable attenuator VA (102 and the optical path transmission unit 103, and reach the wafer 105 to realize exposure. The real value will be measured by the energy sensor 106 in the optical path and reflected to the system. Based on the aforementioned exposure process, when the system receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com