Double-wire middle value pulse MIG welding power system and control method thereof

A power supply system and power supply technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve the effect of reducing influence, speeding up speed and optimizing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

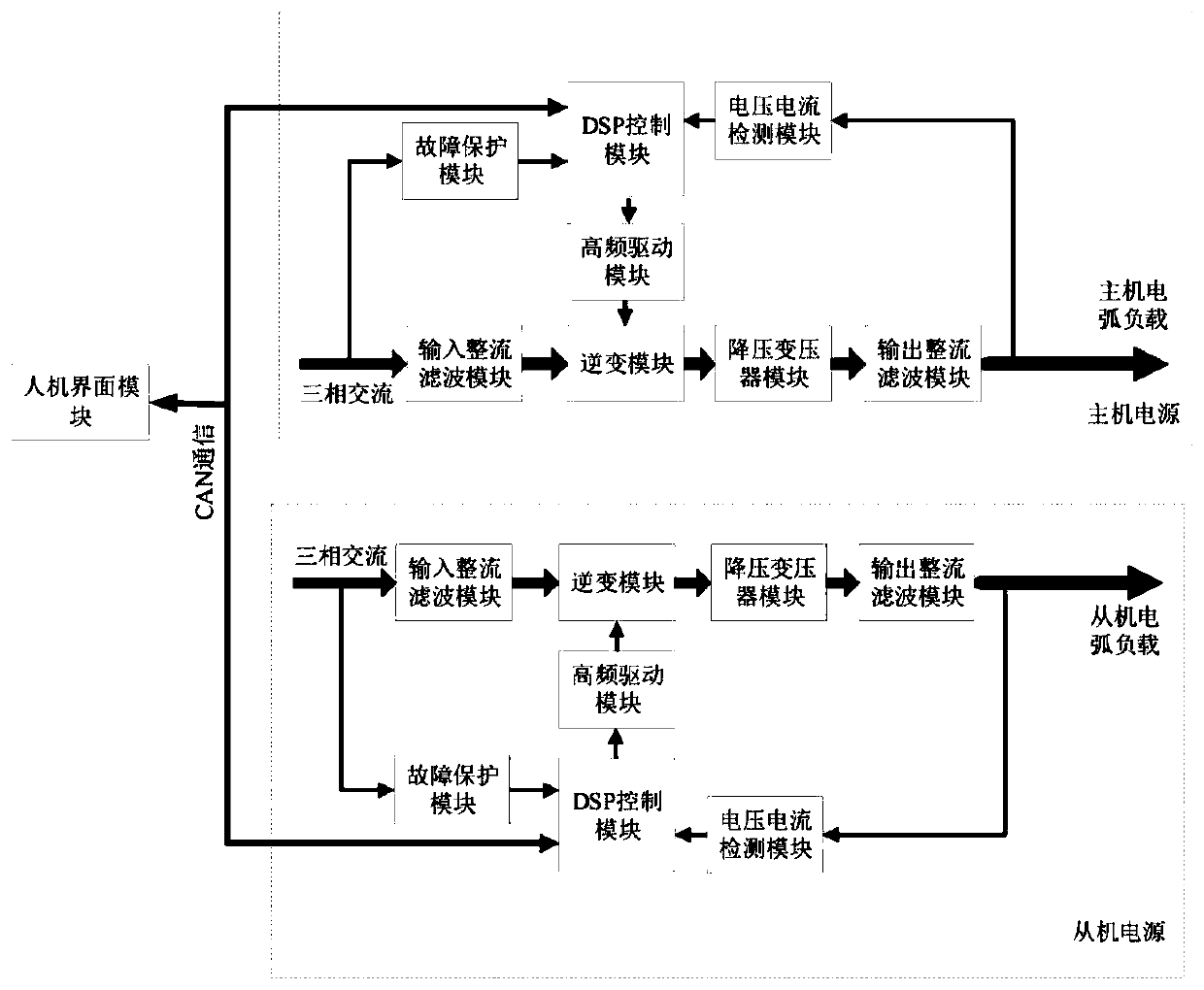

[0056] Such as figure 1 As shown, a dual-wire median pulse MIG welding power system includes a three-phase AC input power grid, a master power supply, a slave power supply, a man-machine interface and an arc load;

[0057] One end of the master power supply is connected to the three-phase AC input grid, and the other end is connected to the arc load; one end of the slave power supply is connected to the three-phase AC input grid, and the other end is connected to the arc load;

[0058] The host power supply and the slave power supply have the same structure, and both include a main circuit, a high-frequency drive module, a DSP control module, a fault protection module, and a voltage and current detection module;

[0059] The main circuit includes an input rectifying and filtering module, an inverter module, a step-down transformer module, and an output rectifying and filtering module connected in sequence; Hard switching or LLC resonant soft switching can be selected as the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com