Glaze material for forming purple glaze, glaze material and preparation method of purple glaze

A glaze, purple mouth technology, applied in the field of ceramics, can solve problems such as poor color rendering effect, achieve good color rendering effect, improve color rendering effect, reduce ripple or cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

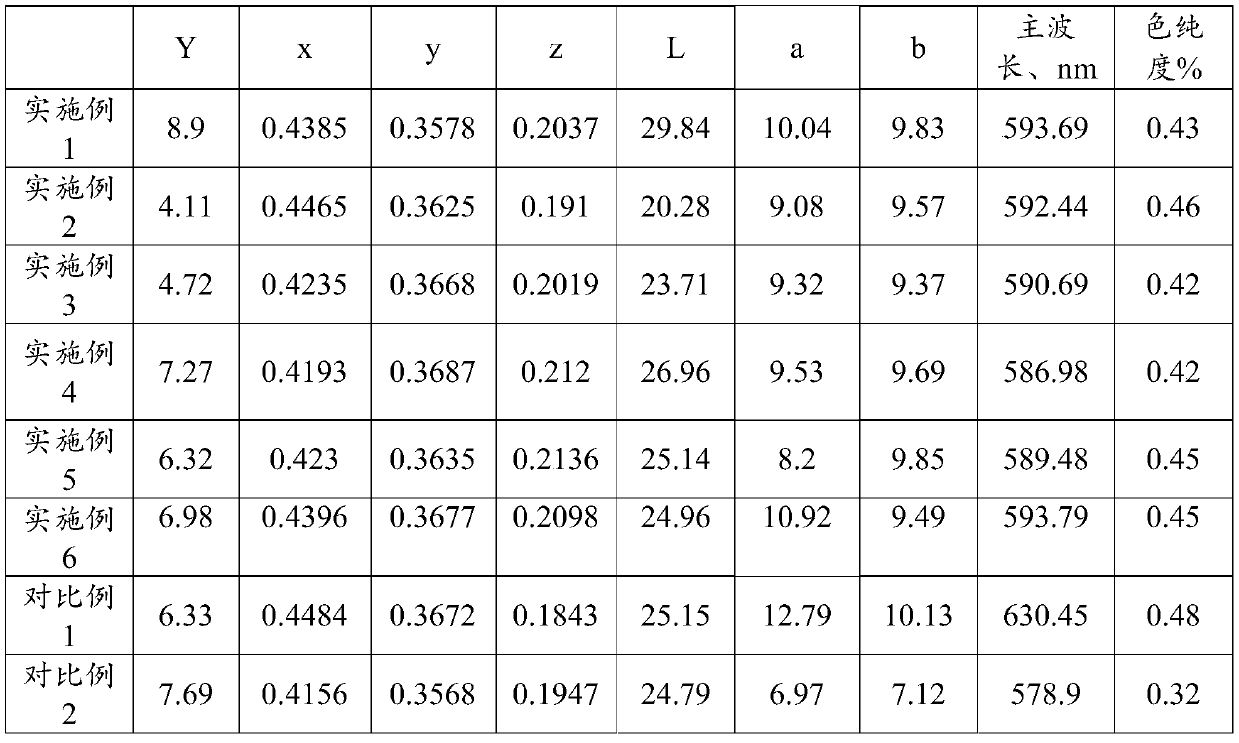

Examples

Embodiment 1

[0037] The present embodiment provides a kind of purple mouth glaze, and its preparation method is as follows:

[0038] Weigh 28kg of potassium feldspar, 46kg of boric acid, 8kg of strontium carbonate, 8kg of zinc oxide, 2kg of calcium borate and 9kg of zircon, mix them uniformly, and then melt them at 1250°C to obtain frit A, which is crushed for later use;

[0039] Weigh 72kg of borax, 8kg of limestone and 24kg of quartz respectively, mix them uniformly, and then melt at 1270°C to obtain frit B, which is pulverized for later use;

[0040] Weigh 21kg of the above pulverized frit A, 64kg of pulverized frit B, 14kg of purple gold soil, and 0.8kg of ferric oxide, and then put them into a ball mill tank for wet ball milling for 40 minutes. After ball milling, the particle size is 10,000 pores Sieve residue ≤ 0.05%; wherein the mixture of pulverized frit A, pulverized frit B, purple gold soil and ferric oxide: ball: water is 1:2:0.8;

[0041] The ball-milled material is dried to ...

Embodiment 2

[0045] The present embodiment provides a kind of purple mouth glaze, and its preparation method is as follows:

[0046] Weigh 35kg of potassium feldspar, 39kg of boric acid, 6kg of strontium carbonate, 10kg of zinc oxide, 7kg of calcium borate and 5kg of zircon, mix them uniformly, and then melt them at 1300°C to make frit A, crush them for later use;

[0047] Weigh 68kg of borax, 16kg of limestone and 12kg of quartz respectively, mix them evenly, and then melt them at 1230°C to make frit B, pulverize them for later use;

[0048] Weigh 26kg of the above pulverized frit A, 53kg of pulverized frit B, 20kg of purple gold soil, and 1.3kg of ferric oxide, and then put them into a ball mill tank for wet ball milling for 20 minutes. After ball milling, the particle size is 10,000 pores Sieve residue ≤ 0.05%; wherein the mixture of pulverized frit A, pulverized frit B, purple gold soil and ferric oxide: ball: water is 1:2:0.5;

[0049] The ball-milled material is dried to a water con...

Embodiment 3

[0053] The present embodiment provides a kind of purple mouth glaze, and its preparation method is as follows:

[0054] Weigh 30kg of potassium feldspar, 43kg of boric acid, 7kg of strontium carbonate, 9kg of zinc oxide, 5kg of calcium borate and 6kg of zircon, mix them uniformly, and then melt them at 1270°C to make frit A, crush them for later use;

[0055] Weigh 69kg of borax, 15kg of limestone and 15kg of quartz respectively, mix them evenly, and then melt them at a temperature of 1250°C to make frit B, crush them for later use;

[0056] Weigh respectively 25kg of the crushed frit A, 57.8kg of the crushed frit B, 16kg of purple gold soil, and 1.2kg of ferric oxide, and then put them into a ball mill tank for wet ball milling for 25min. After ball milling, the particle fineness is 10,000 Hole sieve residue ≤ 0.05%; wherein the mixture of pulverized frit A, pulverized frit B, purple gold clay and ferric oxide:ball:water is 1:2:0.6;

[0057] The ball-milled material is dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap