Ternary cementitious system support mortar

A support mortar and system technology, applied in the field of building materials, can solve the problems of low surface strength, poor volume stability, separation and segregation of support mortar, etc., and achieve good working performance and simple use

Inactive Publication Date: 2020-05-29

PANZHIHUA CITY JIYUAN TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The basic requirements for the mix ratio design of bearing mortar materials need to meet the industry standard TB / T2332-2013 "Basin Bearings for Railway Bridges" issued by the Ministry of Railways. Internal flow performance, etc., the existing patent CN101486545-expansion controllable super early strength bearing mortar material discloses a bearing mortar that can control expansion. It has micro-expansion filling properties. During use, in order to improve the working performance, the slurry often needs to have high fluidity. High fluidity will easily cause the support mortar to be divided into segregation, which will lead to uneven strength development, poor volume stability, and surface Problems such as low strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

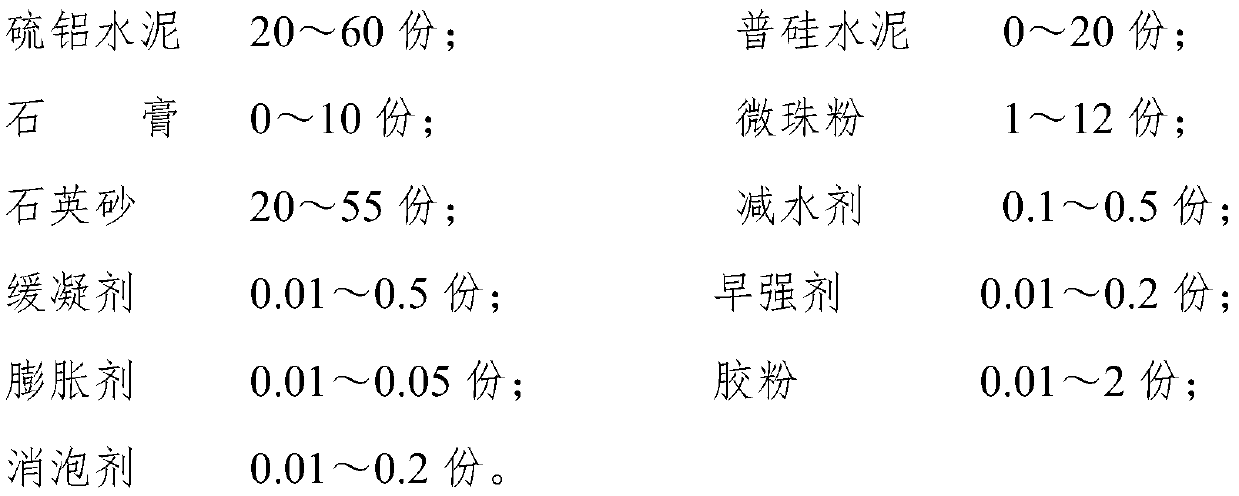

[0032] A ternary cementitious system bearing mortar, comprising the following components, in parts by weight:

[0033]

Embodiment 2

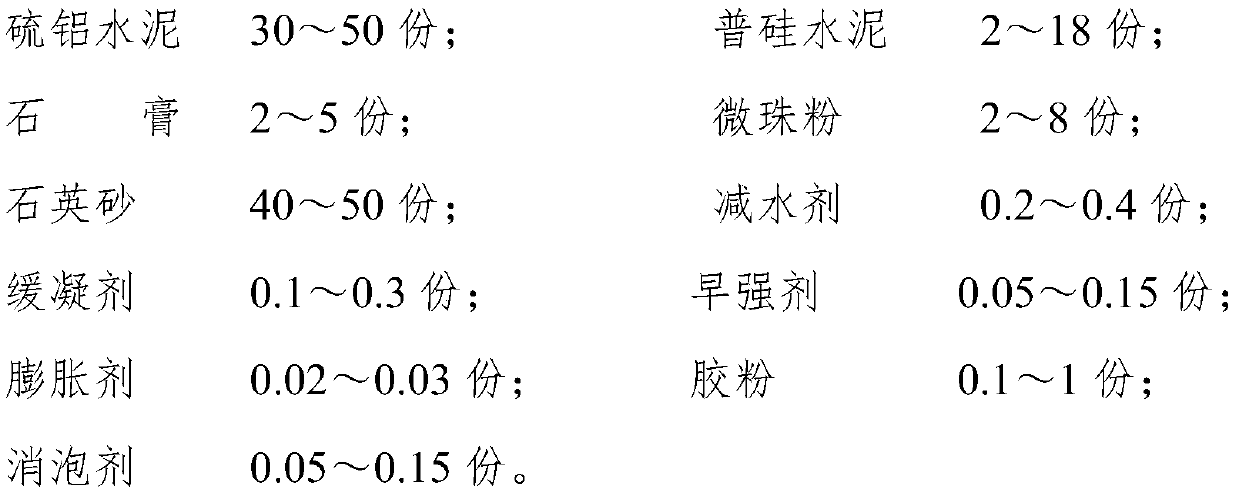

[0035] A ternary cementitious system bearing mortar, comprising the following components, in parts by weight:

[0036]

Embodiment 3

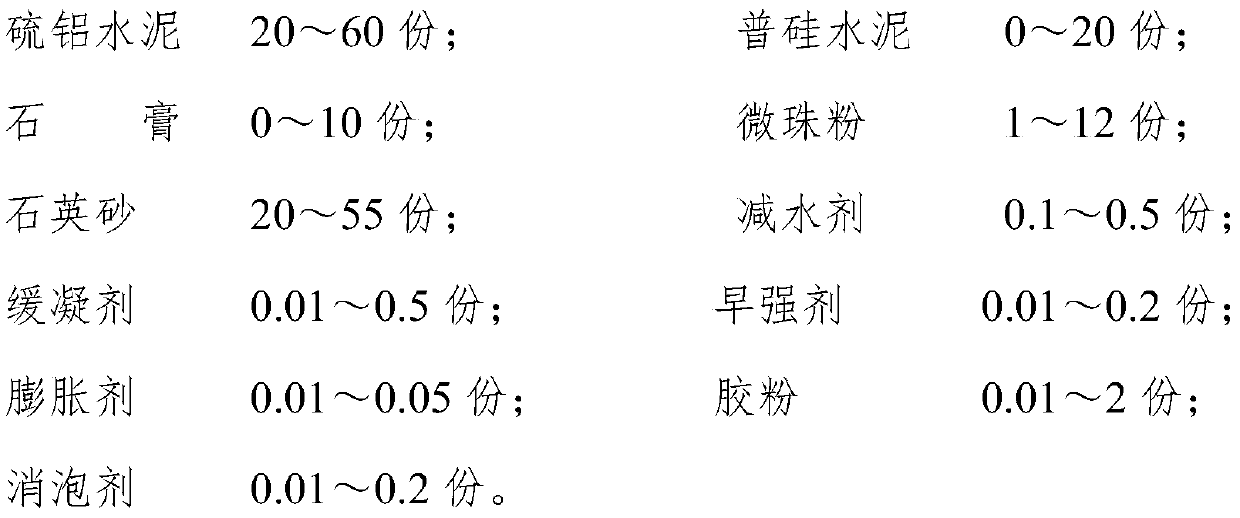

[0038] A ternary cementitious system bearing mortar, comprising the following components, in parts by weight:

[0039]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides ternary cementitious system support mortar which comprises the following components in parts by weight: 20 to 60 parts of sulphoaluminate cement, 0 to 20 parts of ordinary portland cement, 0 to 10 parts of gypsum, 1 to 12 parts of microbead powder, 20 to 55 parts of quartz sand, 0.1 to 0.5 part of a water reducing agent, 0.01 to 0.5 part of a retarder, 0.01 to 0.2 part of anearly strength agent, 0.01 to 0.05 part of an expanding agent, 0.01 to 2 parts of rubber powder, and 0.01 to 0.2 part of an antifoaming agent. According to the invention, the sulphoaluminate cement,the ordinary portland cement and the gypsum are used as a ternary gelling system; additives such as the microbead powder, the water reducing agent, the retarder, the early strength agent, the expanding agent, rubber powder and the defoaming agent are added into the ternary gelling system, so that the support mortar material can meet the performance requirements of 'pot bearings for railway bridges', and particularly, after the microbead powder is added and has a synergistic effect, the prepared support mortar has good properties of segregation resistance, high early strength, high flow state and the like.

Description

technical field [0001] The invention relates to the technical field of building materials, in particular to a ternary cement system bearing mortar. Background technique [0002] Support mortar is a high-performance modified cement-based grouting material. It uses a variety of organic and inorganic additives. It has the characteristics of high strength, no shrinkage, and good durability. The support mortar can be leveled by itself and has a long operating time. After completion, the surface is smooth and flat, which overcomes the shortcomings of traditional mortar such as unevenness, easy cracking, peeling and powdering. [0003] In the bridge design of high-speed railways and railway passenger dedicated lines, for the installation of cast-in-place beam basin rubber bearings and cylindrical rigid bearings, the bearing mortar material needs to meet high durability, high strength, good working performance and economical considerations. sex. [0004] The basic requirements for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/14

CPCC04B28/14C04B2201/50C04B7/32C04B7/02C04B14/22C04B14/06C04B2103/302C04B2103/22C04B2103/12C04B24/125C04B24/129C04B24/085C04B2103/0045C04B2103/50

Inventor 古朝建李宣富张毕军

Owner PANZHIHUA CITY JIYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com