Ultrafine anti-segregation grouting material and preparation method thereof

A grouting material and anti-segregation technology, applied in the field of grouting materials, can solve problems such as easy precipitation, easy agglomeration, and large loss of fluidity over time, so as to improve fluidity and fluidity retention, and good corrosion resistance Excellent performance, durability, and low loss of fluidity over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

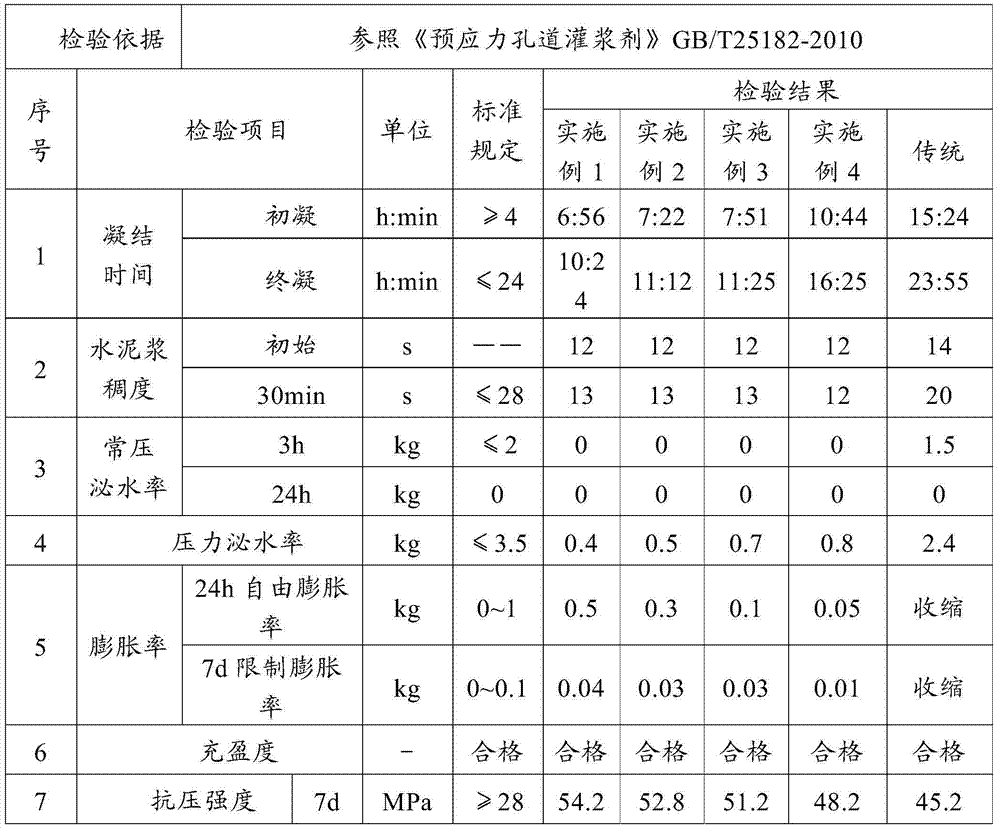

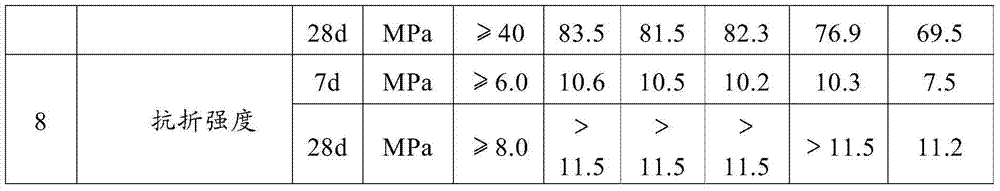

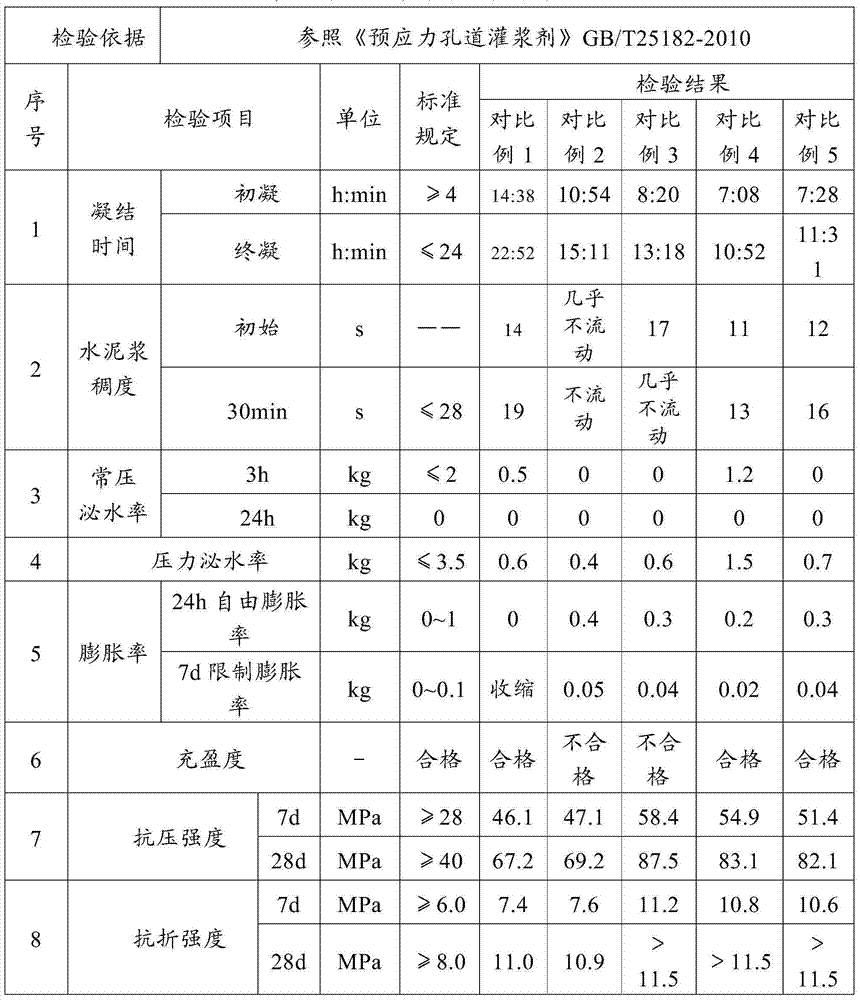

Examples

Embodiment 1

[0041] P·O52.5 cement: 76.56kg; 42.5 grade low-alkali sulfoaluminate cement: 6.8kg; CA50 aluminate cement: 2.3kg; desulfurized gypsum: 1.16kg; silica fume: 6.0kg; ultrafine mineral powder: 6.0 kg; naphthalene-based superplasticizer: 0.9kg; sulfamate-based superplasticizer containing carboxylic acid groups: 0.094kg; sodium gluconate: 0.05kg;

[0042] Sodium tripolyphosphate: 0.12kg; hydroxypropyl methylcellulose ether: 0.009kg; sodium bicarbonate: 0.007kg.

[0043] The above components are fully mixed in a mixer with a flying knife for 5 minutes to 10 minutes.

Embodiment 2

[0045]P O52.5 cement: 81.39kg; 42.5 grade low-alkali sulfoaluminate cement: 5.02kg; CA50 aluminate cement: 1.71kg; desulfurized gypsum: 0.85kg; silica fume: 5.0kg; ultrafine mineral powder: 5.0 kg; naphthalene-based superplasticizer: 0.8kg; sulfamate-based water-reducer containing carboxylic acid groups: 0.076kg; sodium gluconate: 0.04kg; sodium tripolyphosphate: 0.1kg; Cellulose ether: 0.008kg; sodium bicarbonate: 0.006kg.

[0046] The above components are fully mixed in a mixer with a flying knife for 5 minutes to 10 minutes.

Embodiment 3

[0048] P O52.5 cement: 86.24kg; 42.5 grade low-alkali sulfoaluminate cement: 3.21kg; CA50 aluminate cement: 1.11kg; desulfurized gypsum: 0.54kg; silica fume: 4.0kg; ultrafine mineral powder: 4.0 kg; naphthalene-based superplasticizer: 0.7kg; sulfamate-based water-reducer containing carboxylic acid groups: 0.068kg; sodium gluconate: 0.03kg; sodium tripolyphosphate: 0.09kg; hydroxypropylmethyl Cellulose ether: 0.007kg; sodium bicarbonate: 0.005kg.

[0049] The above components are fully mixed in a mixer with a flying knife for 5 minutes to 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com